Cutting method and cutting tool of glass substrate of flexible organic light-emitting diode display

A technology for light-emitting displays and glass substrates, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of forming nicks on glass substrates, unable to effectively cut flexible materials, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate a further understanding of the method, structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

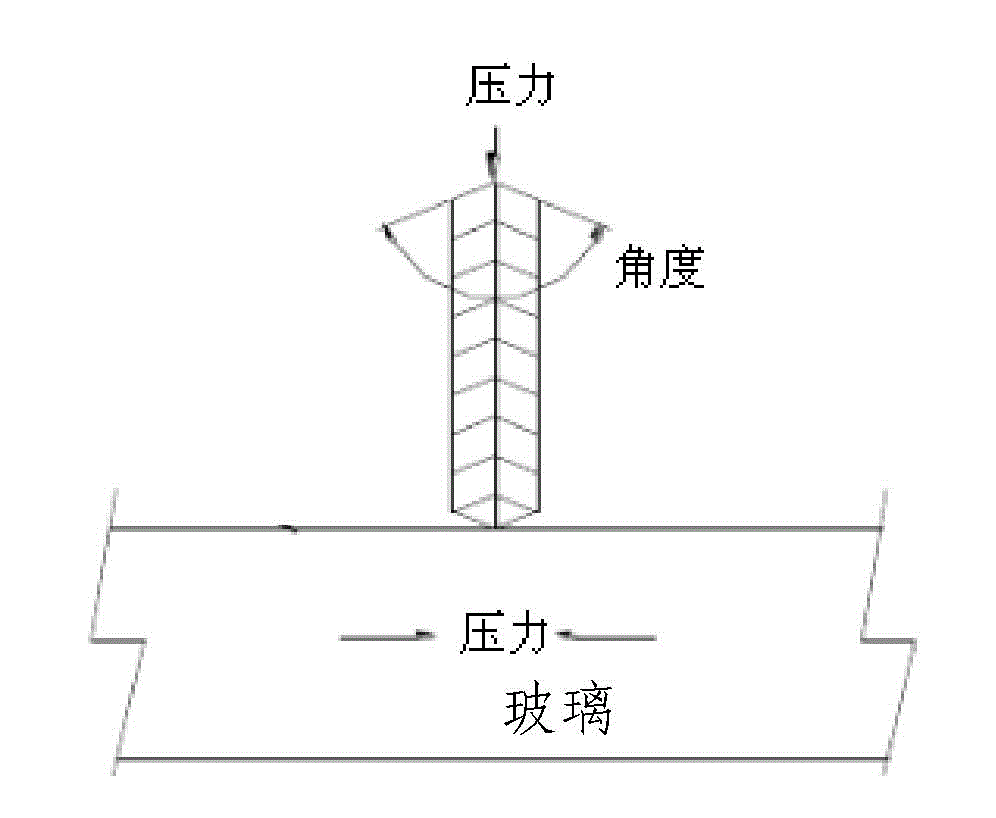

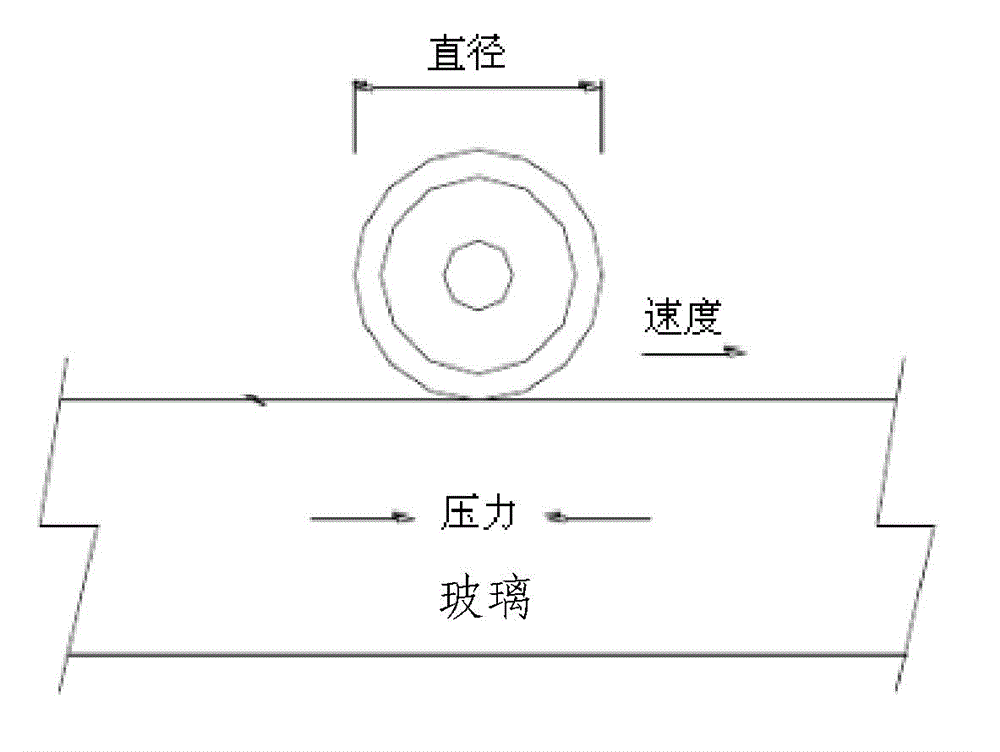

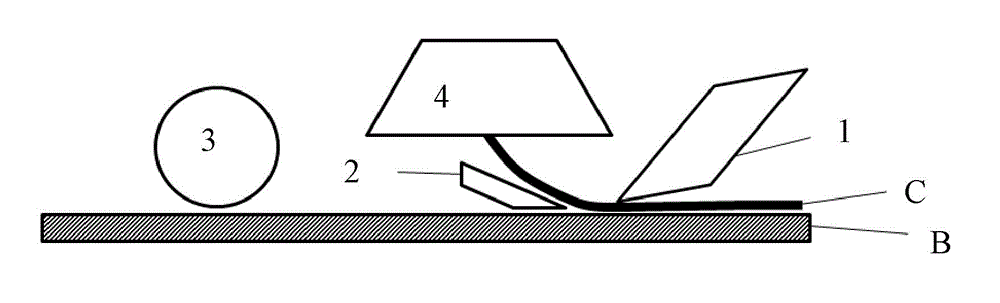

[0032] Such as image 3 and Figure 4 As shown, the cutting tool of the present invention is a combined tool, which includes a pair of blades 1 , a blade 2 and a blade wheel 3 , and the blade 2 is located between the blade 1 and the blade 3 . The cutting tool is used for cutting the glass substrate B of the flexible organic light emitting display and the flexible material C (such as image 3 shown in B and C). The width of the interval between the two blades 1 is adjustable, the distance is 0.3-1.0mm, generally 0.5mm is suitable, and the blade of the blade 1 is at an acute angle, so as to cut the flexible material easily. The flexible material located in the middle part of the two blades 1, after being cut by the blades 1, the edge of the cutting plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com