Special material for copper pollution resistant sockets and preparation method thereof

A technology for special materials and sockets, which is applied in the field of preparation of special materials for anti-copper damage sockets, can solve problems such as copper damage resistance, and achieve the effects of easy insulation, good dispersibility, and good oil extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

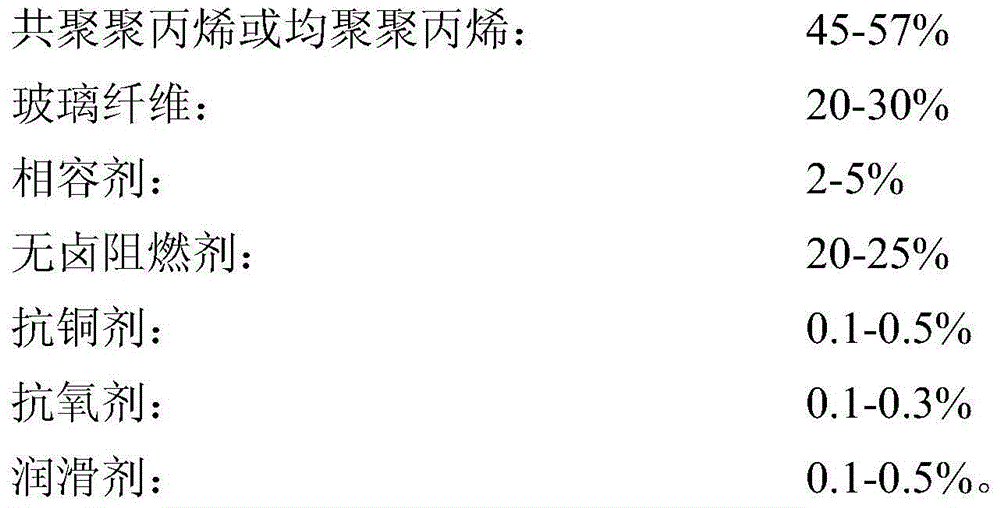

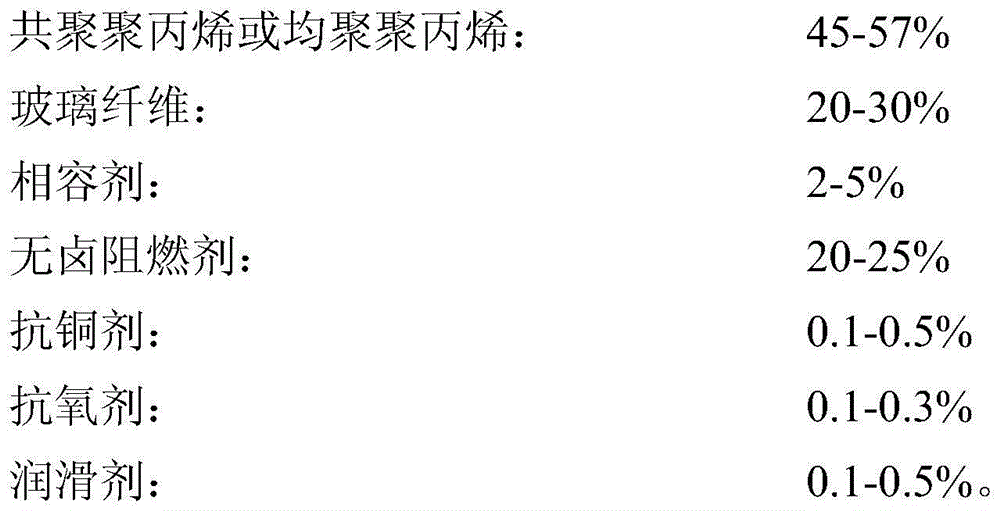

preparation example Construction

[0030] Its preparation method comprises the following steps:

[0031] (1) Weigh the raw materials according to the weight ratio; (2) the above-mentioned materials are extruded and granulated by a twin-screw extruder, the rotating speed of the screw machine is 180-600 rpm, the temperature is 185-205 ° C, and the cold water traction The temperature is 10-40°C

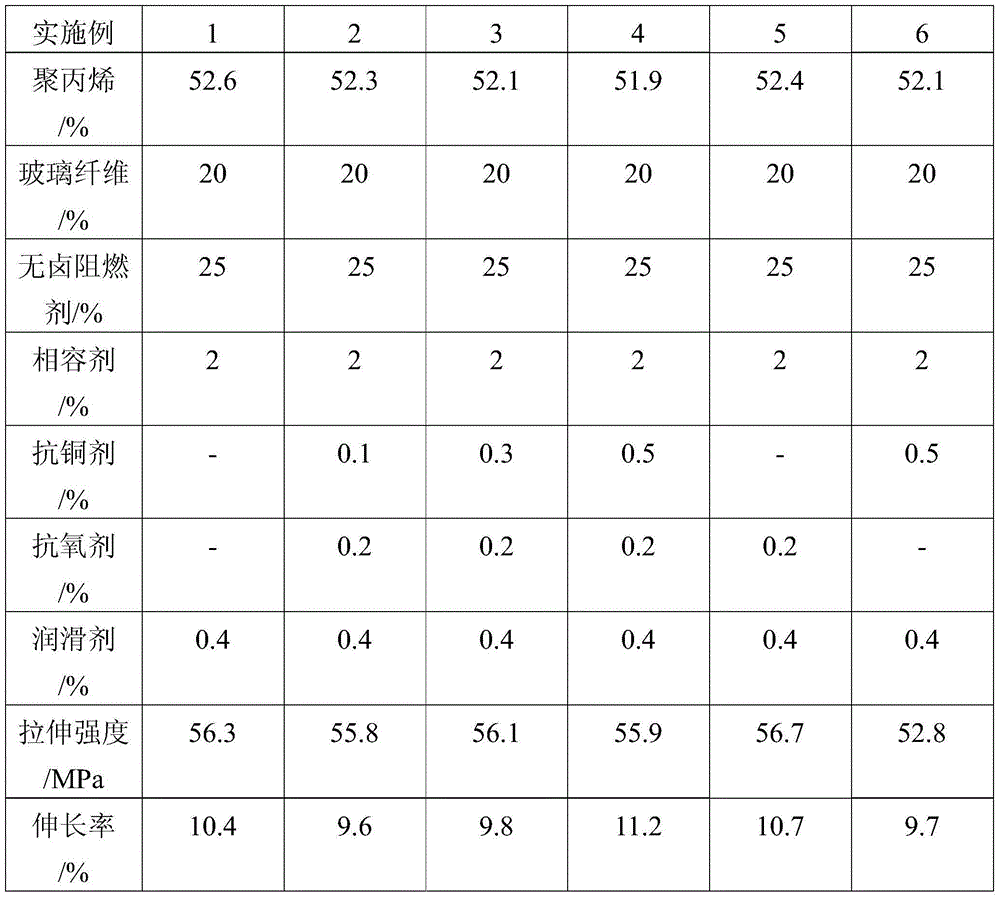

Embodiment 1

[0033] (1) Weigh raw materials according to weight ratio: copolymerized polypropylene or homopolypropylene: 52.6%, glass fiber: 20%, halogen-free flame retardant: 25%, lubricant: 0.4%. Compatibilizer: 2%.

[0034] (2) Blend the above-mentioned raw materials in a high-speed mixer for 5 minutes, and then extrude them from a twin-screw extruder. grain.

Embodiment 2

[0036] (1) Weigh raw materials according to weight ratio: copolymerized polypropylene or homopolypropylene: 52.3%, glass fiber: 20%, halogen-free flame retardant: 25%, compatibilizer: 2%, anti-copper agent (MDA -5): 0.1%, antioxidant (1010 / 168): 0.2% / 0.2%, lubricant: 0.4%.

[0037] (2) Blend the above-mentioned raw materials in a high-speed mixer for 5 minutes, and then extrude them from a twin-screw extruder. grain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com