Solid-core polymer foaming building template and production method thereof

A construction formwork and production method technology, applied in the production of solid polymer foamed construction formwork, in the field of solid core polymer foamed construction formwork, can solve problems such as inconvenient reinforcement, achieve good product quality, ensure market demand, save The effect of time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

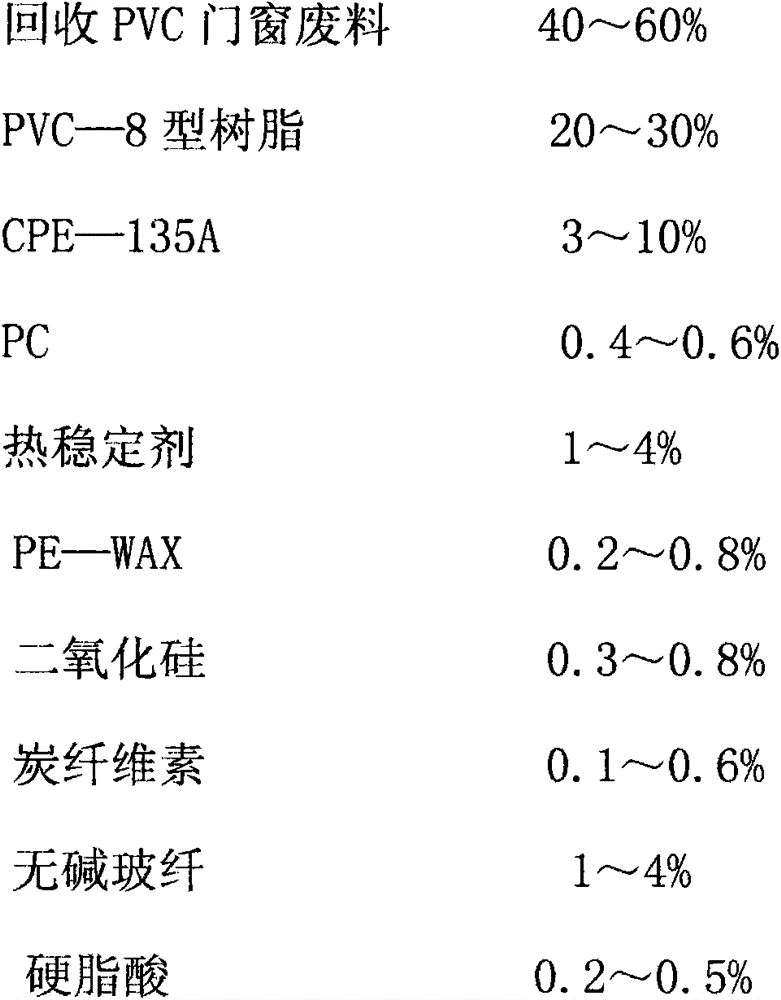

[0024] A solid polymer foam building formwork, comprising the following components and their respective mass fractions:

[0025]

[0026]

[0027] The production method of the above solid polymer foam building formwork includes mixing preparation, extrusion molding and cooling steps, and finally enters the traction. After traction, it is produced according to the length of the required formwork according to the mold size. The selected mold size is 200mm× 15mm; the extrusion molding step is to use a 65 / 132 twin-screw extruder to extrude after heating; the heating temperature is: 170°C in the first zone, 170°C in the second zone, 183°C in the third zone, and 198°C in the fourth zone , 190°C in the fifth zone, and 147°C in the confluent core.

[0028] Among them, the cooling step is to use electric heating water to cool and set the shape. Specifically, the extruded template enters the special water cooling water tank for the setting mold.

[0029] On the basis of the modif...

Embodiment 2

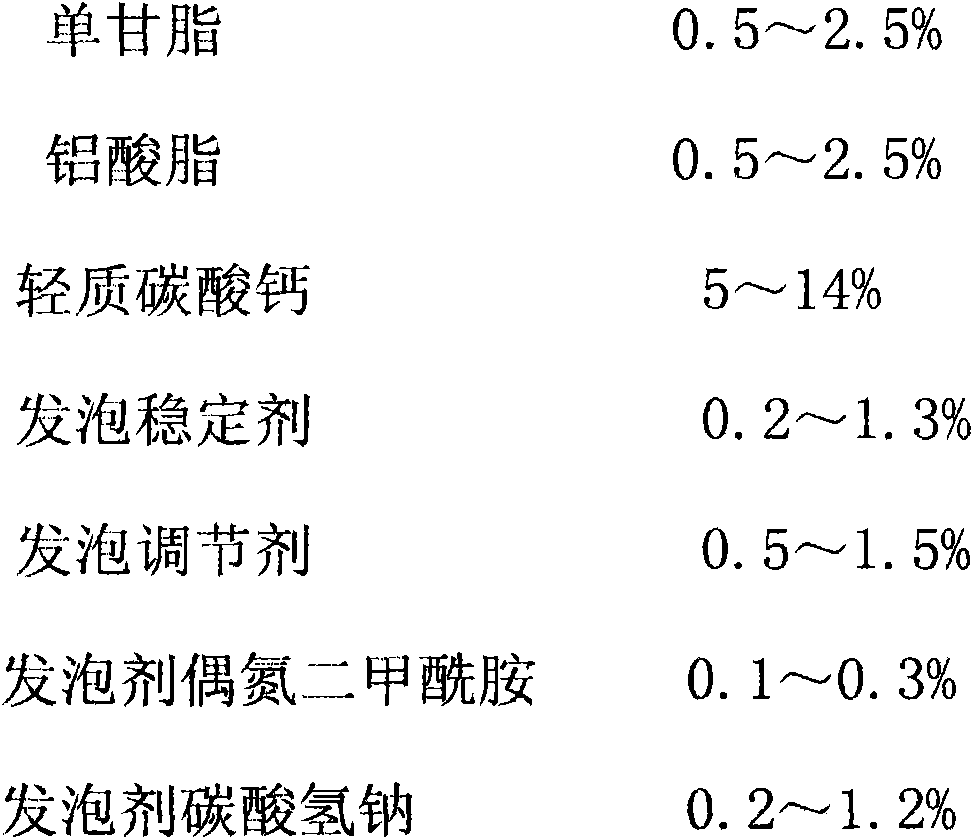

[0031] A solid polymer foam building formwork, comprising the following components and their respective mass fractions:

[0032]

[0033]

[0034] The above production method of solid polymer foamed building formwork includes mixing preparation, extrusion molding and cooling steps, and finally enters traction. After traction, it is produced according to the length of the required formwork according to the length of the mold. The selected mold size is 300mm× 15mm; the extrusion molding step is to use a 65 / 132 twin-screw extruder to extrude after heating; the heating temperature is: 170°C in the first zone, 175°C in the second zone, 180°C in the third zone, and 175°C in the fourth zone , confluence core 165 ℃.

[0035] Among them, the cooling step is to use electric heating water to cool and set the shape. Specifically, the extruded template enters the special water cooling water tank for the setting mold.

[0036] On the basis of the modified PVC formula in this example,...

Embodiment 3

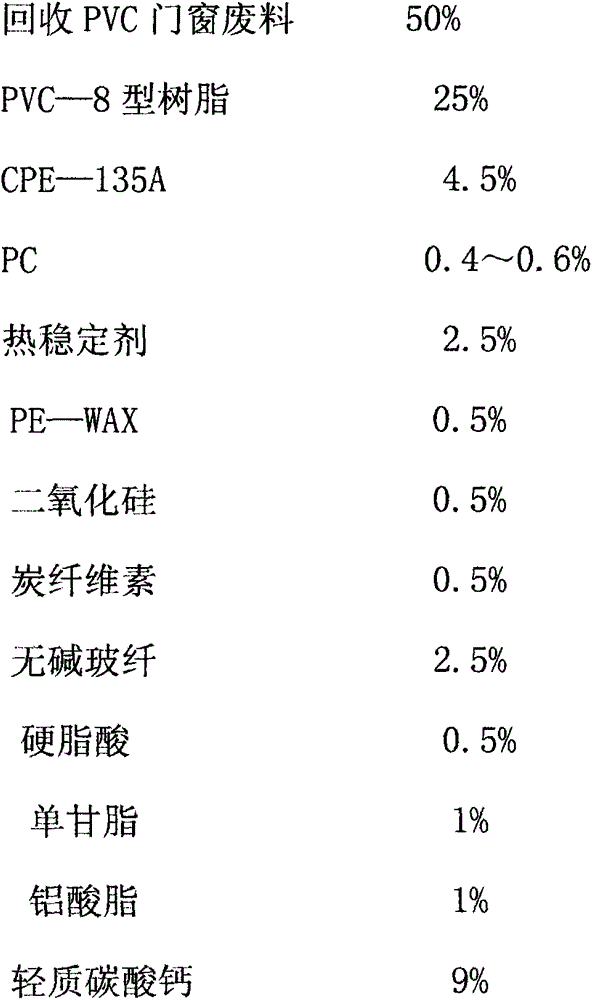

[0038] A solid polymer foam building formwork, comprising the following components and their respective mass fractions:

[0039]

[0040]

[0041] The production method of the above solid polymer foam building formwork includes mixing preparation, extrusion molding and cooling steps, and finally enters the traction. After traction, it is produced according to the length of the required formwork according to the mold size. The selected mold size is 450mm× 15mm; the extrusion molding step is to use a 65 / 132 twin-screw extruder to extrude after heating; the heating temperature is: 170°C in the first zone, 175°C in the second zone, 180°C in the third zone, and 175°C in the fourth zone , confluence core 165 ℃.

[0042] Among them, the cooling step is to use electric heating water to cool and set the shape. Specifically, the extruded template enters the special water cooling water tank for the setting mold.

[0043] The PVC modified formula in this example has the best effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com