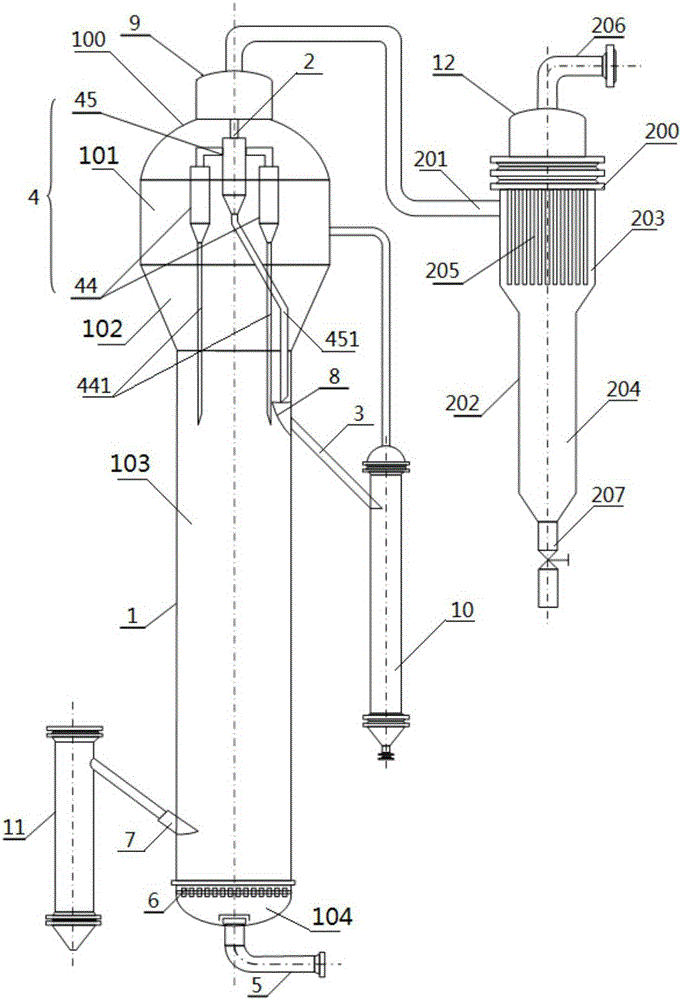

An adsorption desulfurization reaction device and an adsorption desulfurization method

An adsorption desulfurization and reaction device technology, applied in chemical instruments and methods, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of aggravating catalyst particle wear, low catalyst mechanical strength, and increasing device operating costs, and achieves good reaction effects, The effect of less wear and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

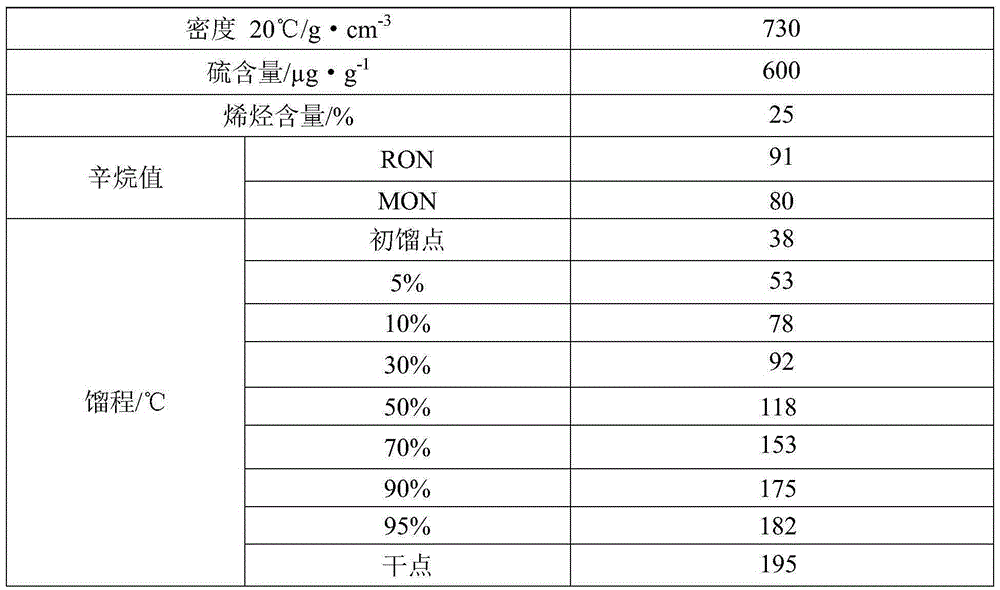

Embodiment 1

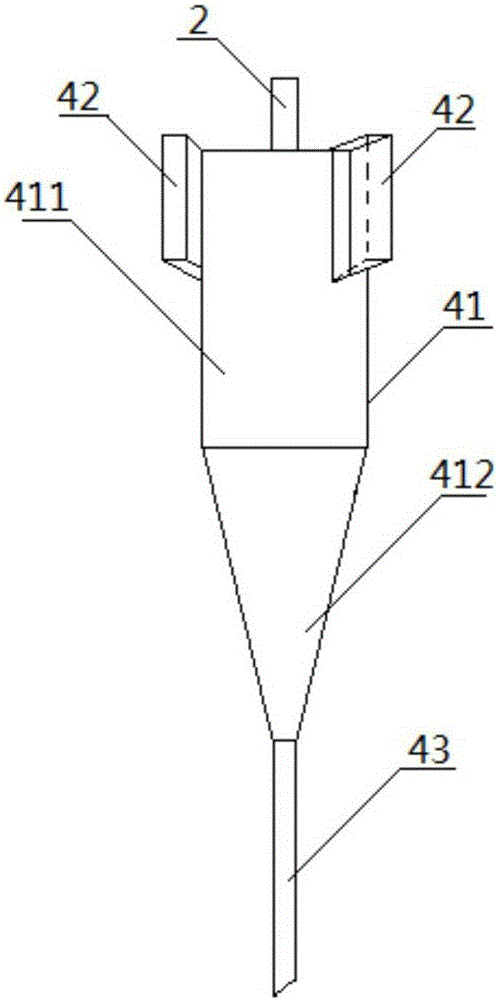

[0088] In this embodiment, the cyclone separator includes a first cyclone separator and a second cyclone separator, the number of material introduction channels of the second cyclone separator and the number of the first cyclone separator are two, and the first cyclone separator Each of the material introduction channels is connected with a first cyclone separator.

[0089] In the cyclone separator used, the cross-section of the material introduction channel is square, arranged along the tangential direction of the hollow body of the cyclone separator, and the number of material introduction channels is 3, and the 3 material introduction channels are along the outer side wall of the straight cylinder area The circumference is set symmetrically; the ratio of the total area of the cross-section perpendicular to the material flow direction of the material introduction channel to the horizontal cross-section area of the separation section is 1:5; the area of each material int...

Embodiment 2

[0103] Adsorption desulfurization is carried out in the same method as in Example 1, the difference is that the number of material introduction channels is 2, and the two material introduction channels are arranged symmetrically along the circumference of the outer side wall of the straight cylinder area; the edge of the material introduction channel is perpendicular to The ratio of the total area of the section where the material flows to the area of the horizontal section of the separation section is 1:24, A 2 / A 1 =6,A 3 / A 2 =0.5;

[0104] The linear velocity of the mixture of sulfur-containing hydrocarbon feedstock and hydrogen in the reaction section is 0.5m / s;

[0105] The linear velocity of the oil mixture at the material introduction channel of the first cyclone separator is 8m / s.

[0106] Continuously for 500 hours. During the reaction, the composition of the obtained oil and gas products was monitored, and the results are listed in Table 4.

[0107] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com