An adsorption desulfurization reaction device and an adsorption desulfurization method

An adsorption desulfurization and reaction device technology, which is applied in the petroleum industry, multi-stage series refining process treatment, hydrocarbon oil treatment, etc. And the effect of stable reaction effect, reduction of operating cost and good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

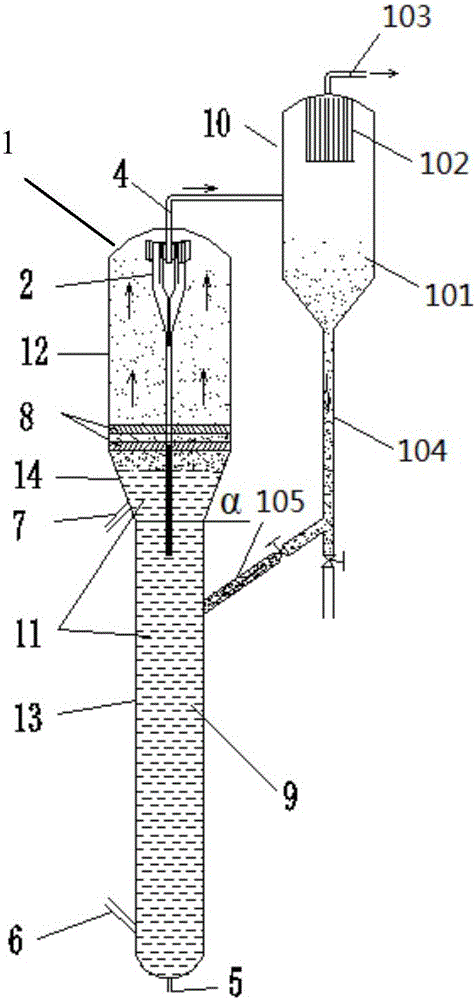

[0103] In this example, the structure of the fluidized bed reactor is as follows.

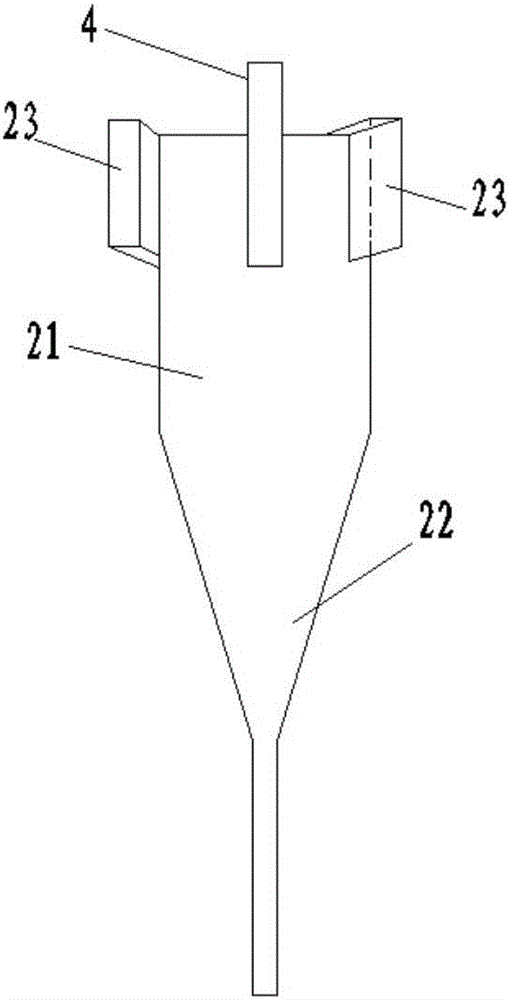

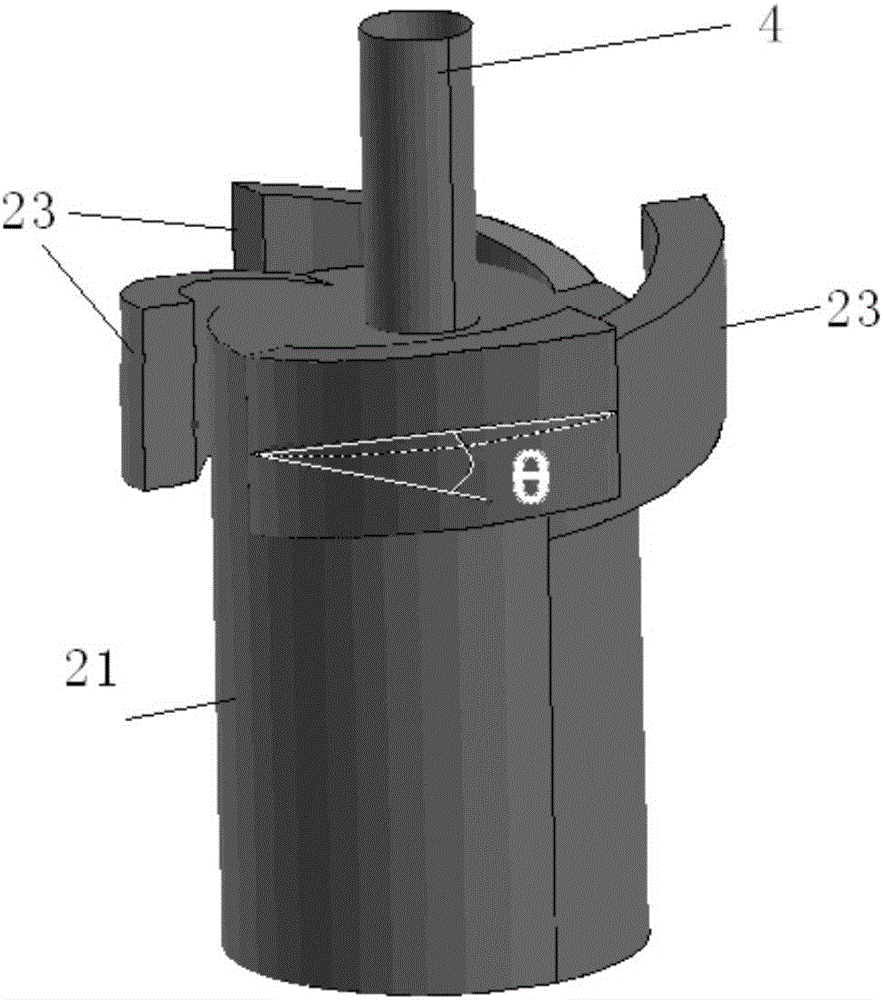

[0104] (1) The upper part of the settling zone is provided with a nested first cyclone gas-solid separator and a second cyclone gas-solid separator, the top of the first cyclone gas-solid separator is connected with the second cyclone gas-solid separator. The tops of the solid separators are connected, wherein, the straight cylinder areas of the two cyclone gas-solid separators are respectively provided with 4 guide air inlet passages along the tangential direction, and the circumferential direction of the guide air inlets in the straight cylinder areas is set evenly;

[0105] (2) The cross-section of the air-guiding channel is square and the outline of the air-guiding channel is a logarithmic spiral curve. From a point on the inlet end of the air-guiding channel and between the air-guiding channel and the straight cylinder The angle θ between the straight line determined by the point correspo...

Embodiment 2

[0127] Adsorption desulfurization was carried out in the same manner as in Example 1, except that no internals were set between the reaction zone and the settling zone.

[0128] Continuously for 500 hours. During the reaction process, the following indicators are monitored: (1) The composition of the obtained oil and gas products; (2) The average particle size of the catalyst in the catalyst fine powder storage tank and the catalyst dense bed in the fluidized bed reactor; (3) Fluidization The dilute phase density in the settling zone of the bed reactor, the results are listed in Table 4.

[0129] After reacting for 500 hours, the content of the catalyst having a particle size of less than 30 μm in the catalyst in the dense-phase bed in the fluidized bed reactor was 5.9% by weight. After 500 hours, 2.5 kg of catalyst fine powder was collected in the catalyst fine powder storage tank.

[0130] Table 4

[0131]

[0132] *: Based on the antiknock index of sulfur-containing g...

Embodiment 3

[0148] Adopt the method identical with embodiment 1 to carry out adsorption desulfurization, difference is:

[0149] The included angle between the straight line determined by a point on the inlet end of the guide air inlet channel and the point corresponding to the point on the port where the guide air inlet channel meets the straight barrel area and the horizontal plane is 5°;

[0150] The area of the inlet end leading to the air inlet channel is A 231 =200mm 2 , the area of the port where the guide air inlet channel connects with the straight barrel area is A 232 , A 231 / A 232 =2;

[0151] Adsorption desulfurization conditions include: the contact temperature is 420°C, the pressure is 4MPa in absolute pressure, the sulfur-containing hydrocarbon feedstock enters the reactor at a speed of 0.3m / s, and the oil mixture in the settling zone flows at a speed of 3.5m / s Enter the guide air intake channel.

[0152] Continuously for 500 hours. During the reaction process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com