A kind of method for hydrothermal cracking of high acid crude oil

A hydrothermal cracking, high acid crude oil technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of difficult sewage treatment, complex device design, high processing cost, reduce coking and save operating costs , the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

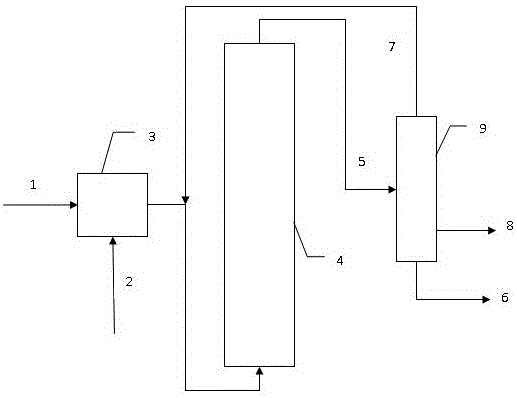

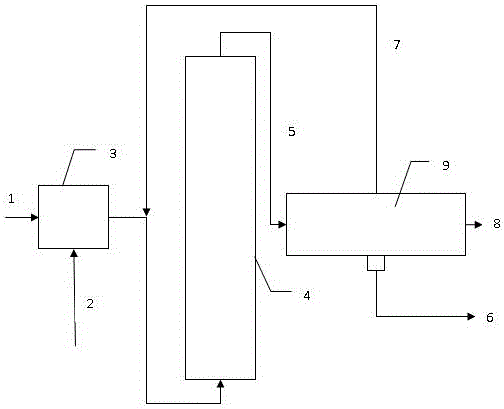

Image

Examples

Embodiment 1

[0036] This example is an implementation of the processing of high sour crude oil.

[0037] The properties of the raw materials used in the test are listed in Table 1. It can be seen from Table 1 that the acid value of the raw material is 4.58 mgKOH / g, which belongs to high-acid crude oil. The mixing valve in the electric desalination process is used as the oil-water mixer, and the oil-water mixing conditions are shown in Table 2.

[0038] The hydrogen hydrothermal cracking reactor is a circular straight cylindrical high temperature and high pressure reactor with no reactor components inside. The reaction conditions and results of hydrogen hydrothermal cracking are shown in Table 2.

Embodiment 2

[0040] This example is an implementation of the processing of high sour crude oil.

[0041] The properties of the raw materials used in the test are listed in Table 1. The mixing valve in the electric desalination process is used as the oil-water mixer, and the oil-water mixing conditions are shown in Table 2.

[0042] The hydrogen hydrothermal cracking reactor is a circular straight cylindrical high temperature and high pressure reactor with no reactor components inside. Using a vertical high-pressure separator, the hydrothermal cracking reaction conditions and results are shown in Table 2.

[0043] Table 1 Properties of high sour crude oil

[0044] project data Density (20℃), g / cm 3

[0045] Table 2 Experimental conditions and results

[0046] project Example 1 Example 2 oil-water mixing condition Water injection volume, mass% 18.0 30.0 Mixing strength, MPa 0.05 0.05 Hydrothermal Cracking Reaction Conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com