Hydroprocessing method of coker gasoline

A technology of coking gasoline and hydrotreating, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of main reactor temperature rise impact, difficult operation control, economic loss, etc., and achieve quality improvement and reduction Severity, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

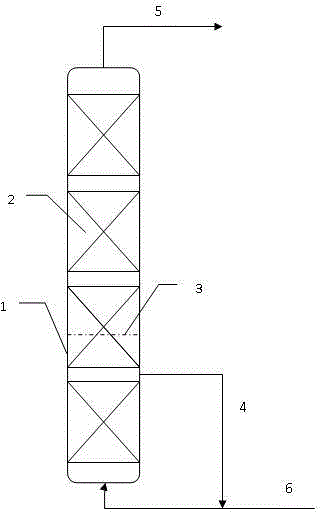

[0029] according to figure 1 In the reactor structure shown, the catalyst bed gradation decreases from bottom to top in order of particle size, and the void ratio of the catalyst bed also decreases in order. The three catalysts are FH-40C, FHRS-1, and FZC-102B developed and produced by Fushun Petrochemical Research Institute. Hydrogen protectant. The main properties of the catalyst are shown in Table 1. The volume ratio of the three catalyst beds of FZC-102B, FHRS-1 and FH-40C is 2:2:6. The raw material oil is coker gasoline, and the circulating oil is coking diesel oil. The properties of raw material oil and circulating oil are shown in Table 2. The process conditions and product properties after 2 months of operation are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com