A gallium-based liquid alloy with low temperature fluidity, preparation process and thermometer

A low-temperature fluidity, liquid alloy technology, used in thermometers, thermometers based on material expansion/contraction, instruments, etc., can solve problems such as difficulty in ensuring stable operation, temperature limitations of gallium-based alloys, etc., to ensure normal use and stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The liquid alloy composition and proportion (weight percent) of the present embodiment are as follows:

[0035]

[0036] The preparation process is:

[0037] Five high-purity metals (purity above 99.9%) of gallium, indium, tin, bismuth and silver are prepared according to the above formula requirements, and put into a vacuum induction melting furnace (the crucible of which is a quartz crucible, which can avoid contamination of the alloy melt) ), and then vacuumize the vacuum induction melting furnace, so that the pressure in the furnace is 2*10 -3 Pa; start the heating process, heat the metal mixture to 1000°C, and melt all kinds of metals into a whole; at this time, reduce the heating power, refine the melted alloy at 750°C for one minute to achieve complete homogenization, and then Turn off the heating power; after cooling, remove the vacuum to take out the liquid alloy to reduce the degree of oxidation. The surface layer of the obtained liquid alloy in contact w...

Embodiment 2

[0043] The liquid alloy composition and proportion (weight percent) of the present embodiment are as follows:

[0044]

[0045]

[0046] The preparation process is:

[0047] Five high-purity metals (purity above 99.9%) of gallium, indium, tin, bismuth and silver are prepared according to the above formula requirements, and put into a vacuum induction melting furnace (the crucible of which is a quartz crucible, which can avoid contamination of the alloy melt) ), and then vacuumize the vacuum induction melting furnace, so that the pressure in the furnace is 2*10 -3 Pa; start the heating process, heat the metal mixture to 1200°C, and melt various metals into a whole; at this time, reduce the heating power, refine the melted alloy at 800°C for one minute to achieve complete homogenization, and then Turn off the heating power; after natural cooling, the vacuum is released to take out the liquid alloy.

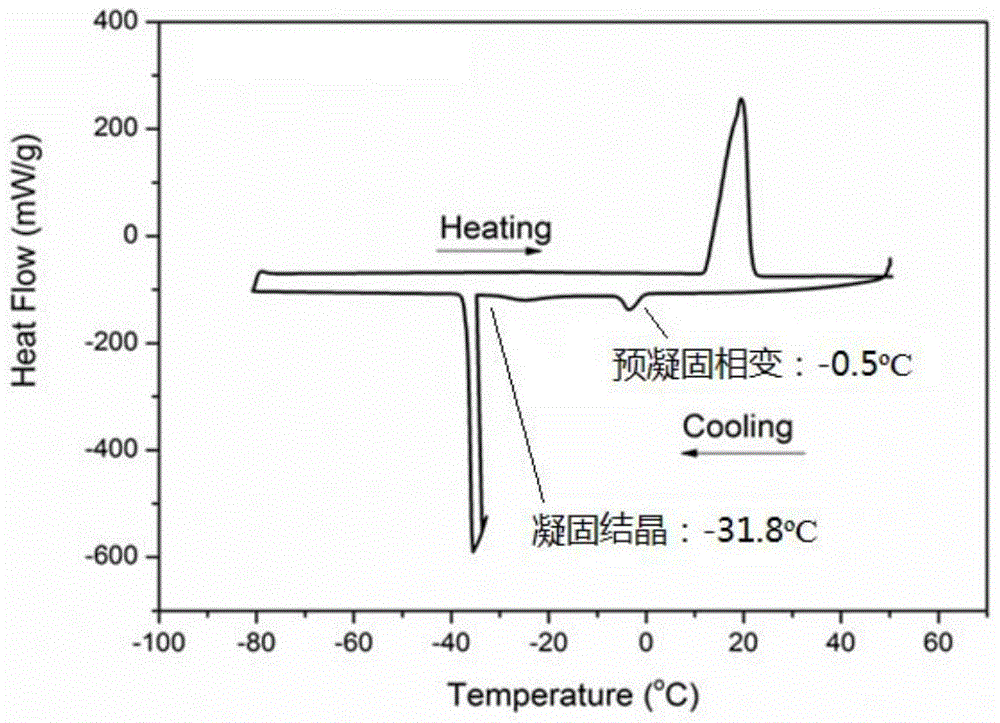

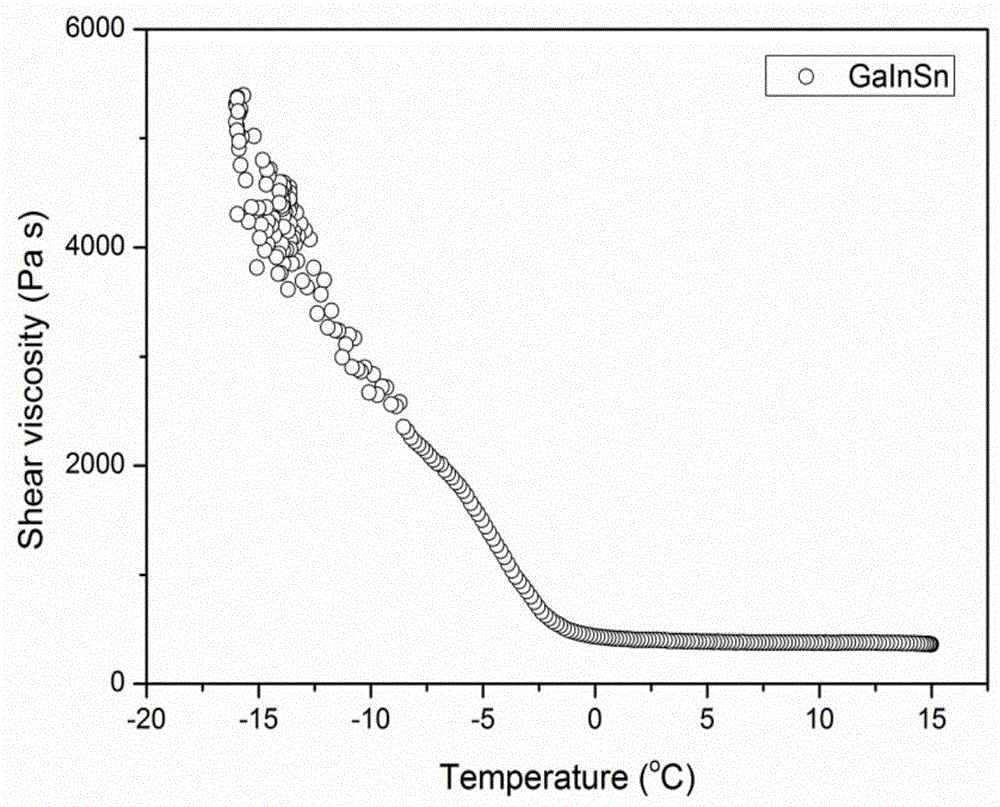

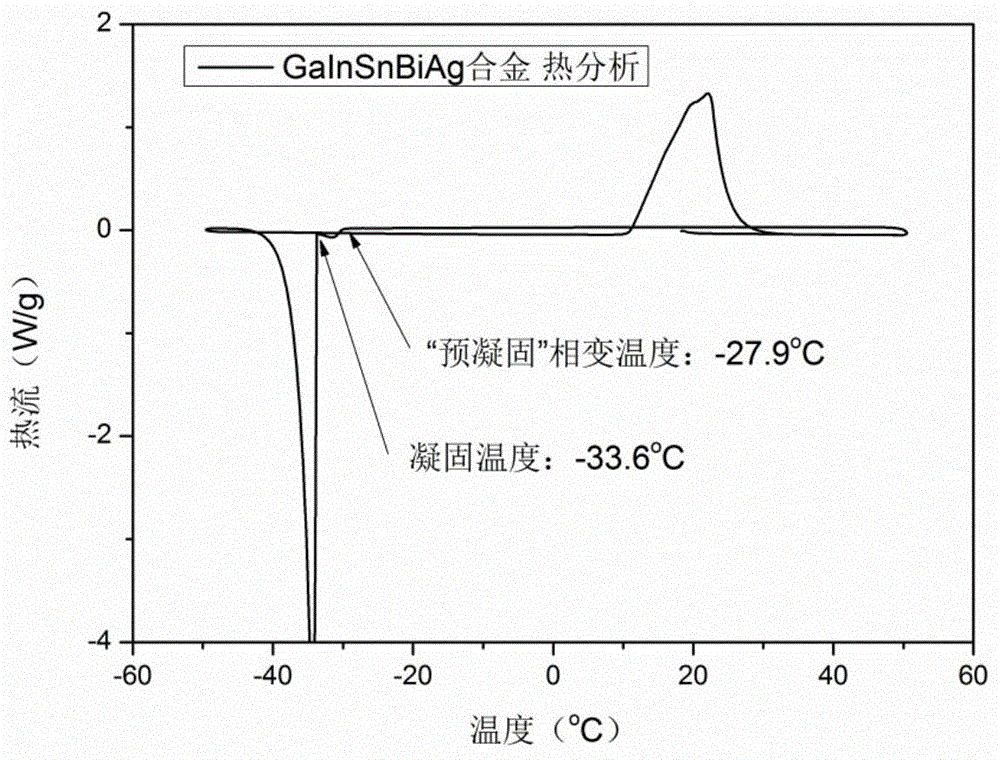

[0048] Its phase transition temperature was measured by differential scan...

Embodiment 3

[0051] The liquid alloy composition and proportion (weight percent) of the present embodiment are as follows:

[0052]

[0053] The preparation process is:

[0054] Five high-purity metals (purity above 99.9%) of gallium, indium, tin, bismuth and silver are prepared according to the above formula requirements, and put into a vacuum induction melting furnace (the crucible of which is a quartz crucible, which can avoid contamination of the alloy melt) ), and then vacuumize the vacuum induction melting furnace, so that the pressure in the furnace is 2*10 -3 Pa; start the heating process, heat the metal mixture to 1150°C, and melt various metals into a whole; at this time, reduce the heating power, refine the melted alloy at 750°C for one minute to achieve complete homogenization, and then Turn off the heating power; only after it has completely cooled, release the vacuum to take out the liquid alloy.

[0055] Its phase transition temperature was measured by differential scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com