Closing method for passageway bus bar

A busbar and aisle technology, applied in the field of electrolyzers, can solve problems such as heavy workload and labor intensity of workers, great influence on the normal production of electrolyzers, and potential safety hazards of power supply equipment, so as to reduce operation items, shorten power outage time, and reduce operation risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

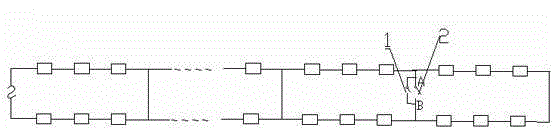

[0009] Such as figure 1 As shown, the present invention comprises the following steps: 1. A discharge device is set between the two ends A and B of the busbar, and the discharge switch 1 of the discharge device is in an off state; 2. After the series electrolyzer 3 is powered off, switch 1 is turned on ; 3. Discharge by the discharge device. The discharge by the discharge device reaches a voltage drop of less than 0.1V at the breakout point, completing the short-circuit discharge. 4. Close the aisle bus switch 2 .

[0010] The discharge device is connected in parallel to both sides of the aisle bus break.

[0011] The discharge device is a circuit breaker, and the circuit breaker controlled remotely is equipped with a power consumption load.

[0012] By installing a short-circuit discharge device on both sides of the short-circuit port of the channel bus, it can quickly balance the voltage, and the closing operation can be performed directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com