Classification and Treatment of High Liquid Limit Soil in Subgrade Engineering

A high-liquid-limit soil and treatment method technology, which is applied in infrastructure engineering, soil protection, roads, etc., can solve the problems of high-liquid-limit soil with high fine particle content, high natural moisture content, high liquid limit, etc., and achieve reduction The effect of spoiling or borrowing soil quantity, improving project quality and saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below through specific examples, but the use and purpose of these exemplary embodiments are only used to exemplify the present invention, and do not constitute any form of any limitation to the actual protection scope of the present invention, nor will the present invention The scope of protection is limited to this.

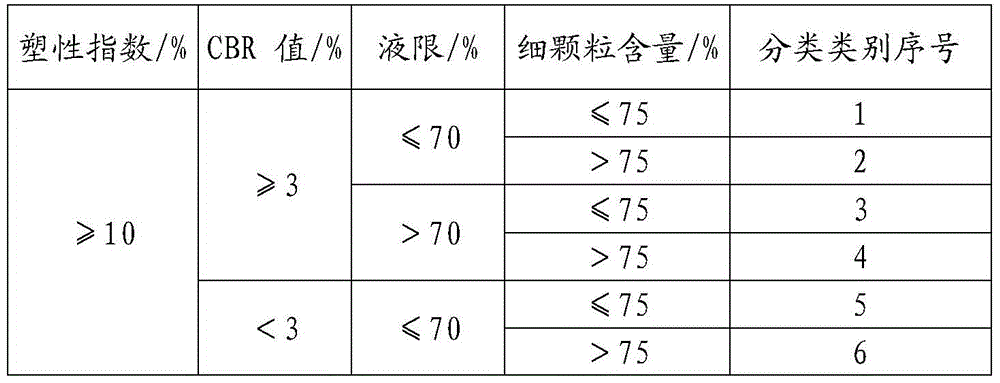

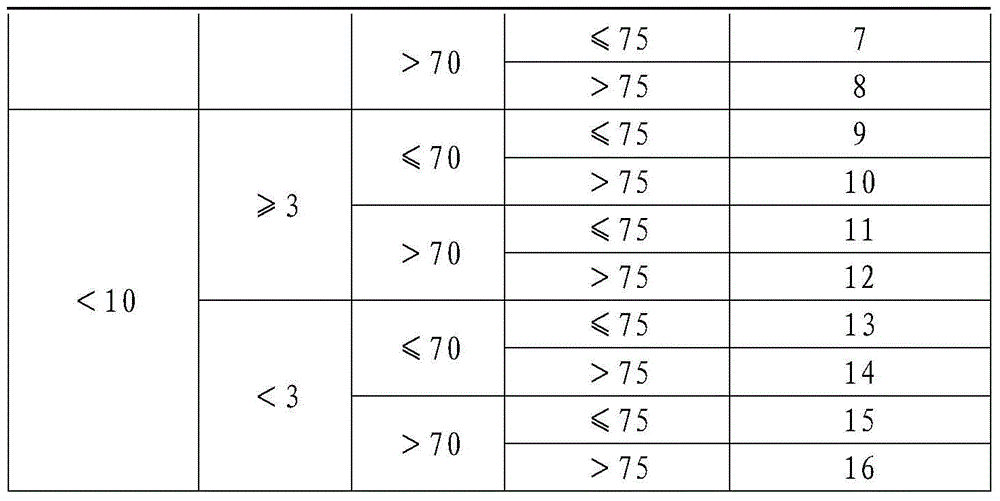

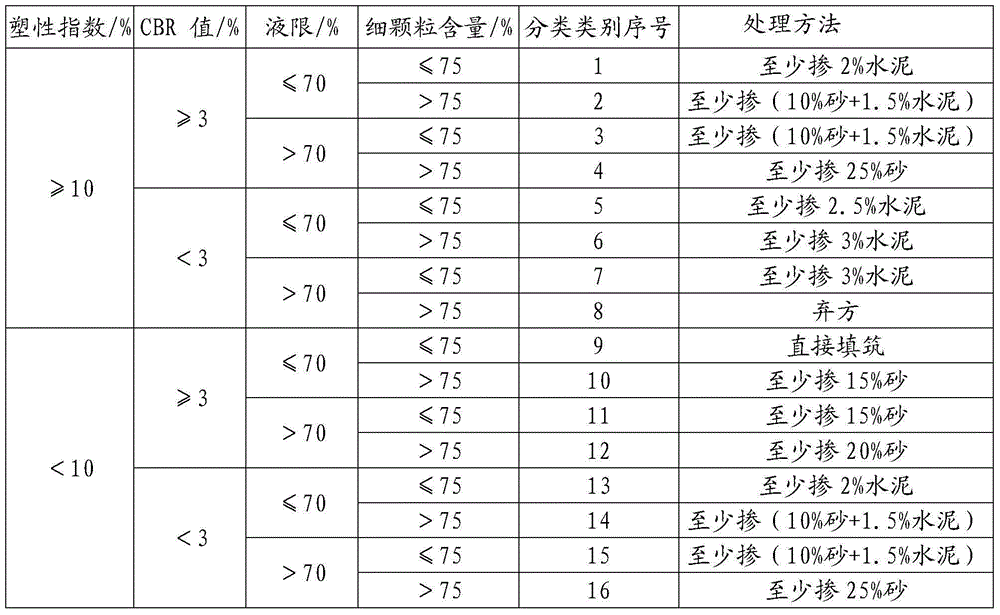

[0031] A method for classifying and processing high liquid limit soil in subgrade engineering, comprising the following steps:

[0032] S1. Mix the high liquid limit soil with a certain amount of quicklime for stewing treatment, thereby reducing the natural moisture content of the soil; since the natural moisture content of high liquid limit soil is generally large, the effect of adding quicklime to reduce the soil moisture content is very obvious , so generally the high liquid limit soil is mixed with quicklime and stewed by the field mixing method, and the amount of quicklime mixed with the high liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com