Shock absorption device of automobile

A shock absorber, automobile technology, applied in the direction of shock absorbers, springs/shock absorbers, springs, etc., can solve the problems of poor shock absorber effect and short service life, and achieve the effects of convenient maintenance, long service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

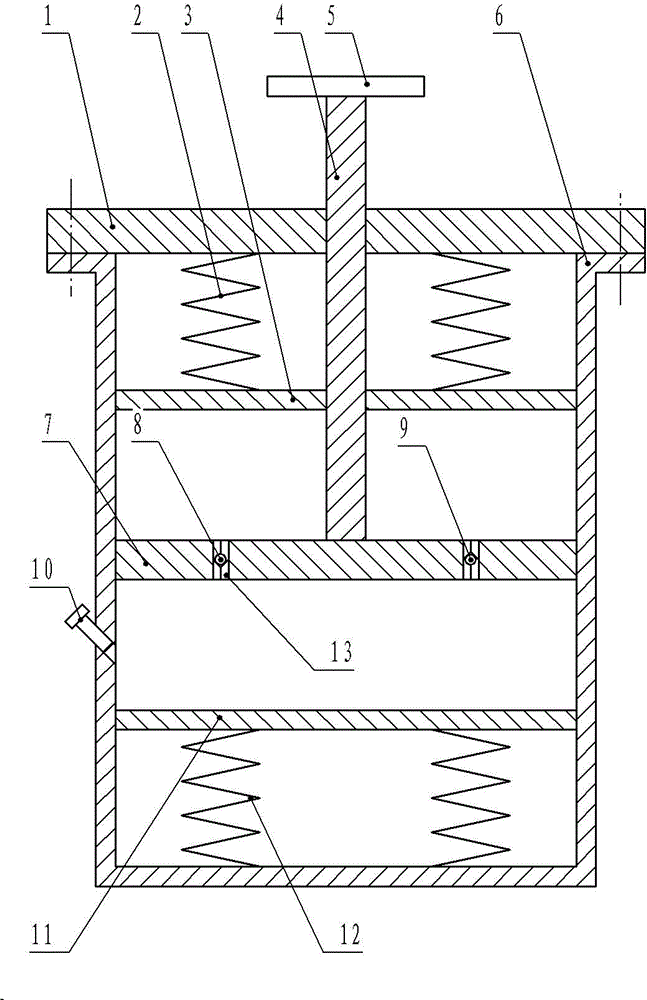

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: figure 1 as shown,

[0014] This automobile shock absorber includes a cylinder body 6 and a cylinder head 1 matched with the cylinder body 6, a piston 7, and a piston rod 4. The upper end of the piston rod 4 is provided with a connecting plate 5, and the piston 7 is provided with several even-numbered Through hole 13, half of through hole 13 is equipped with first one-way valve 8, and its other half is equipped with second one-way valve 9, and the direction of first one-way valve 8 is arranged as from bottom to top, and the second one-way valve The direction of 9 is set from top to bottom, the first one-way valve 8 and the second one-way valve 9 are one-way valves with damping holes; The outer diameters of the cylinders are the same, the lower baffle 11 and the bottom of the cylinder body 6 are equipped with a lower spring 12, the upper part of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com