An automatic detection device for a backplane connector

A technology for automatic detection devices and backplane connectors, applied to measuring devices, instruments, etc., can solve problems such as inability to ensure good contact of sockets, large overall insertion and withdrawal force, and large clamping force of fixtures, etc., to shorten the average time, The effect of high degree of automation and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

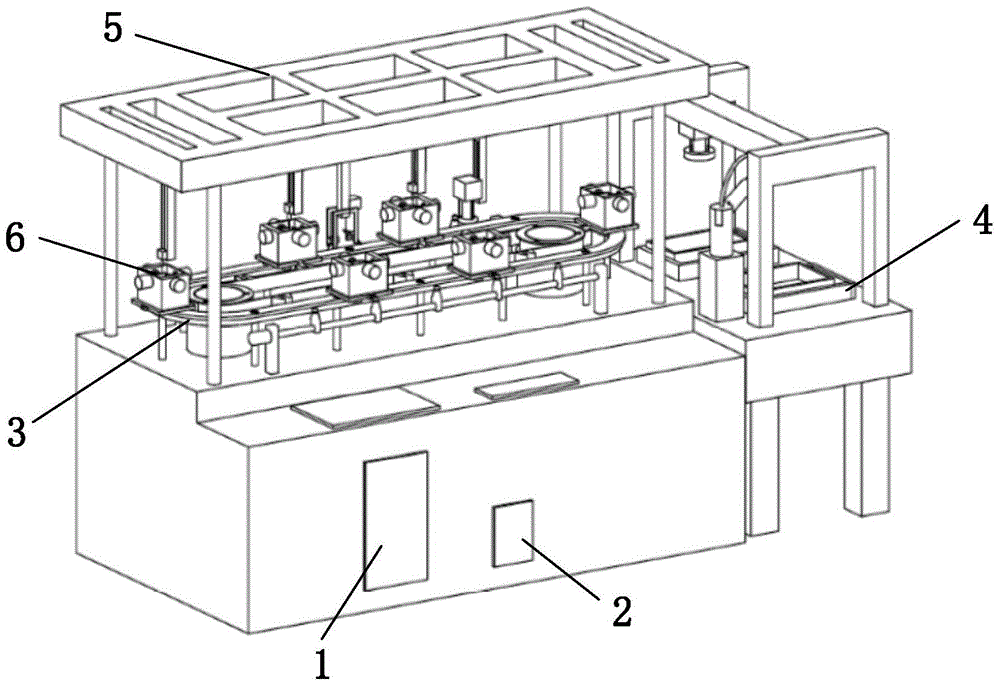

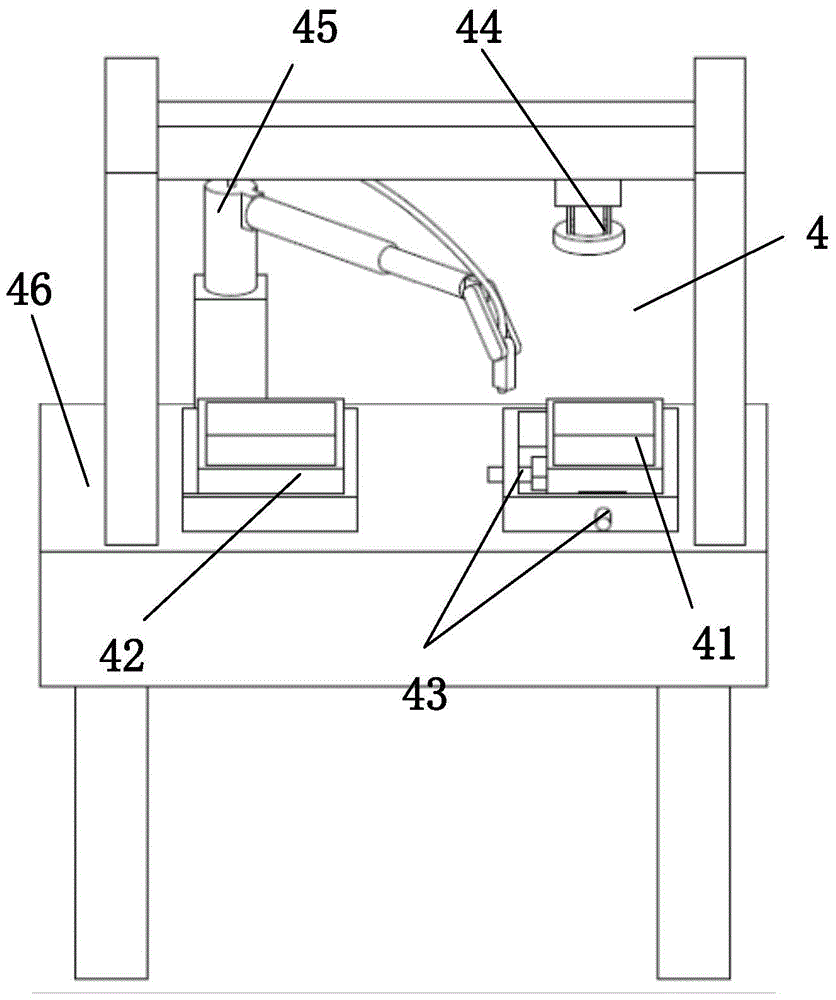

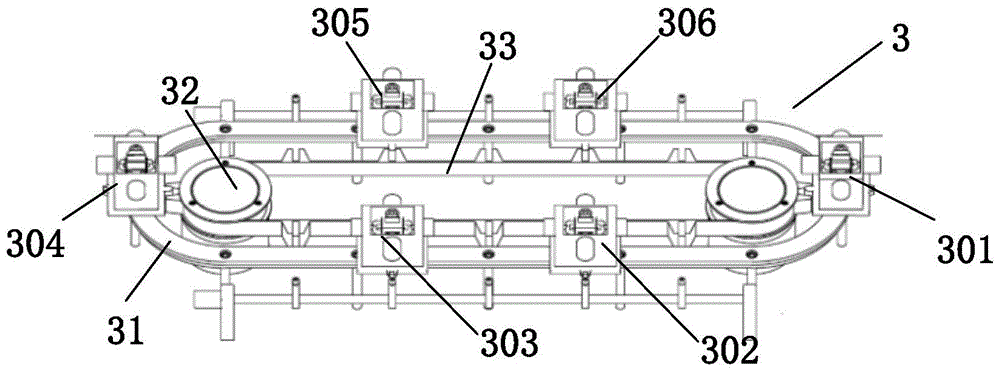

[0032] The device of the present invention can automatically detect the key parameters affecting the electrical connection performance of the backplane connector, including: appearance detection, silk screen reading, pin alignment measurement, pin insertion alignment measurement, reed opening size measurement , The position detection of the reed in the jack, and the measurement of the insertion force. Such as figure 1 As shown, the device is equipped with a host computer 1, a loading and unloading unit 4, a detection unit 5, a fixture 6, a motion control unit 2, and a transmission unit 3.

[0033] The host computer 1 runs the host computer software, and the database of the host computer software stores the information of various types of backplane connectors: the geometric dimensions of the backplane connector, the position distribution of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com