Rock creep-seepage coupling test system

A test system and creep technology, applied in the direction of permeability/surface area analysis, using stable tension/pressure to test material strength, measuring devices, etc., can solve the problem that seepage and creep laws are rarely involved and hinder the development of rock creep theory and other issues to achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1 Test equipment and equipment

[0014] 1.1 Introduction to the test system

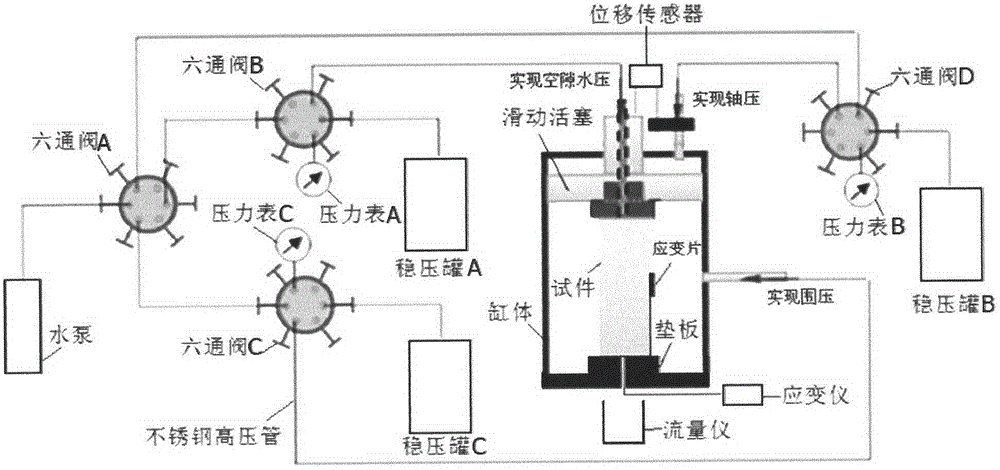

[0015] Rock creep-seepage coupling test system, see figure 1 , Including water pump, six-way valve, stainless steel high-pressure pipe, pressure gauge, surge tank, sliding piston, cylinder, test piece, strain gauge, strain gauge, backing plate, displacement sensor and flow meter.

[0016] The six-way valve includes six-way valve A, six-way valve B, six-way valve C and six-way valve D. Pressure gauges include pressure gauge A, pressure gauge B, and pressure gauge C. The surge tank includes surge tank A and voltage regulator. Tank B and surge tank C.

[0017] By adjusting the switch of six-way valve A, confining pressure loading, axial pressure loading and pore water pressure loading can be realized. The strain gauge can be used to measure the deformation of the coal before failure, the displacement sensor can be used to measure the deformation of the coal after failure, and the flow meter can measure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com