A kind of cyclic oxidation experiment device controlled by crank-slider mechanism and oxidation performance test method

A crank-slider mechanism and cyclic oxidation technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming, laborious, cumbersome, and lack of hot-cold cycle oxidation, and achieve the effect of shortening the experiment time and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

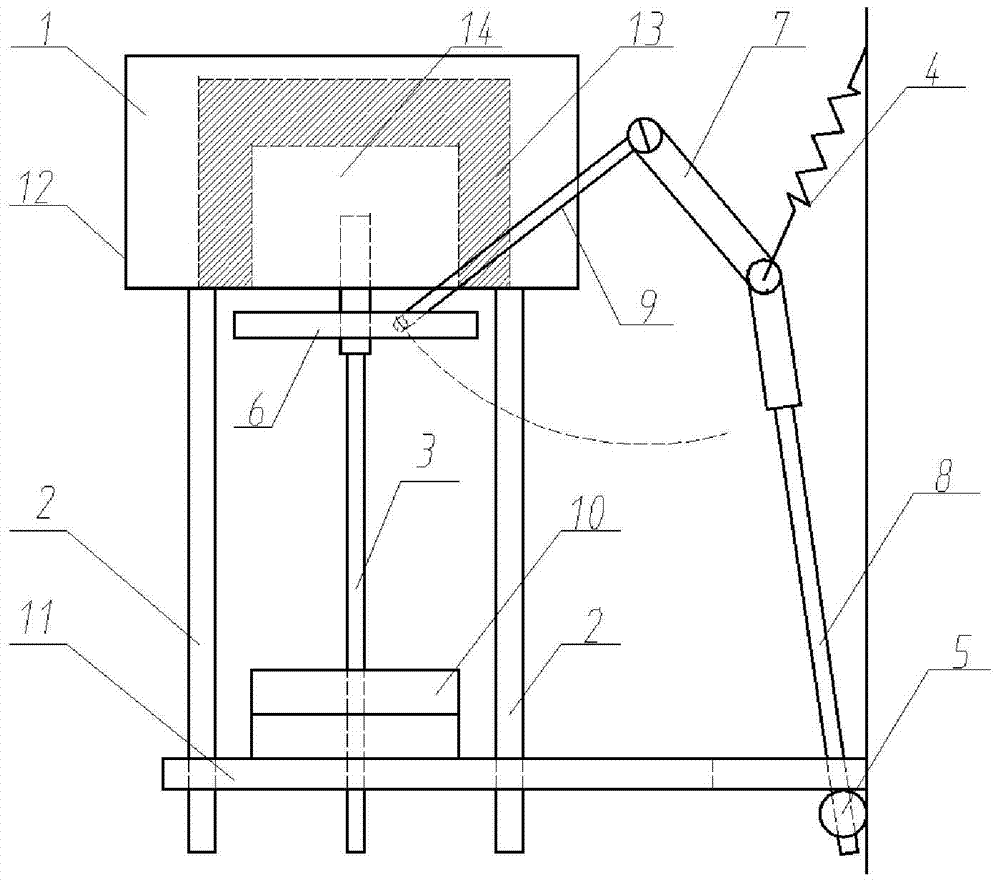

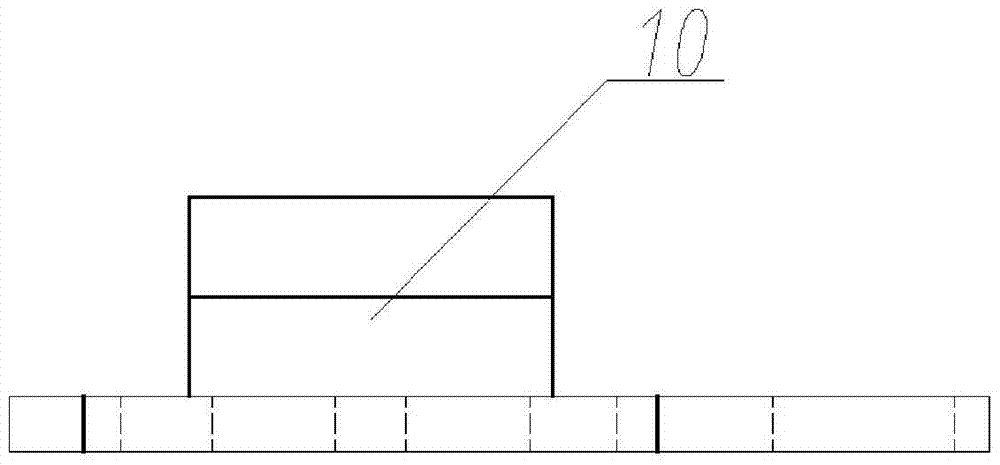

[0028] See figure 1 The cyclic oxidation experiment device controlled by the crank slider mechanism of the present invention is used to realize the automatic test of the oxidation performance of the alloy in the corrosive environment of the cold-heat cycle; it is composed of a heating furnace 1, a support system and a control system.

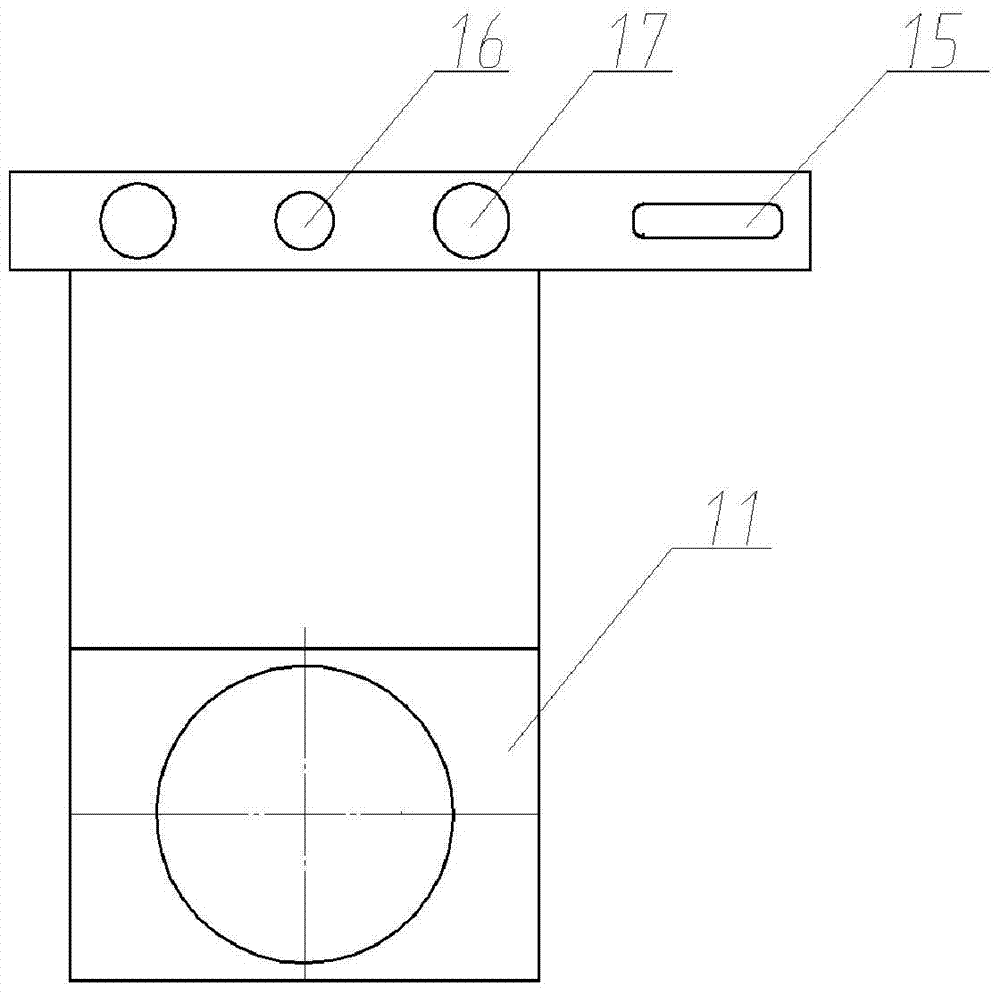

[0029] The heating furnace 1 provides a heat source for the experimental samples. It includes a stainless steel shell 12 and a furnace 14 made of cylindrical refractory bricks arranged in the stainless steel shell 12. The furnace 14 is provided with heating elements and thermocouples. The furnace 14 and the stainless steel shell 12 There is an insulation layer 13; the insulation layer 13 is made of ordinary refractory brick or ceramic fiber, and the heating element can be selected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com