System and method for testing cooling performance of quenching medium based on ZigBee

A quenching medium and cooling performance technology, applied in the field of quenching medium cooling performance test system, can solve the problems of easy data loss, troublesome serial port operation, etc., achieve good compatibility, satisfy multi-point measurement, and high sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

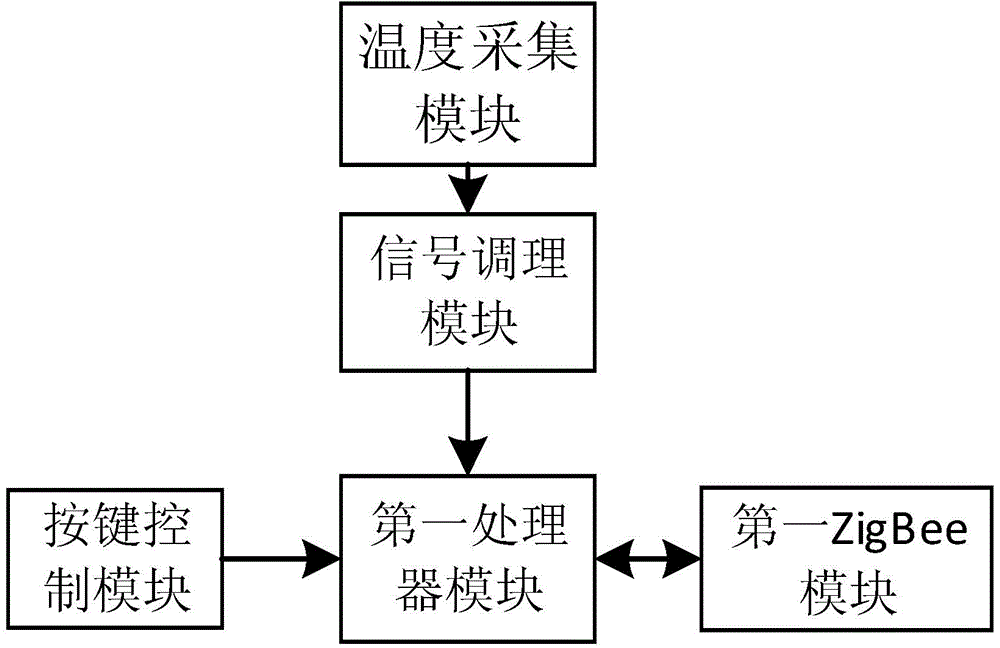

[0018] figure 1 A functional block diagram of the temperature collection terminal of the present invention is shown.

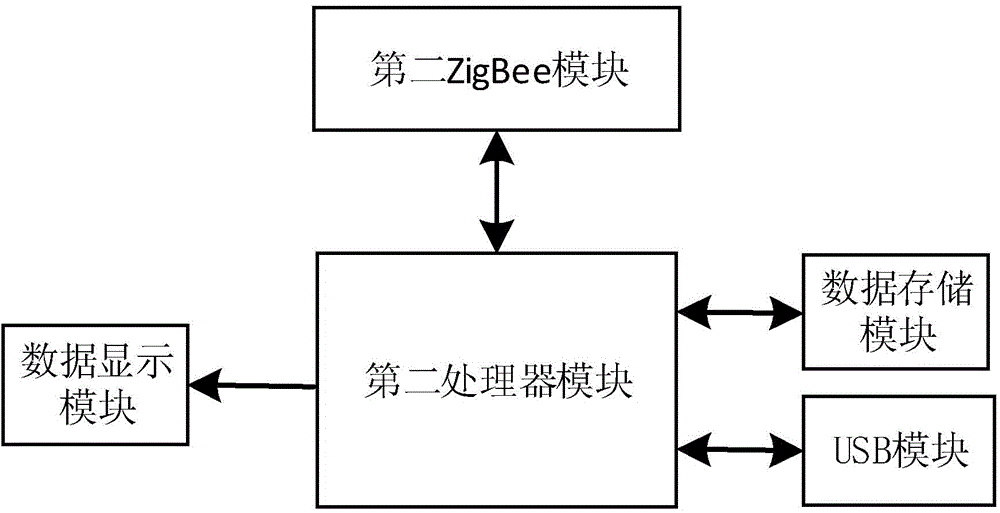

[0019] figure 2 A functional block diagram of the data processing terminal of the present invention is shown.

[0020] like figure 1 and figure 2 Shown, a kind of quenching medium cooling performance testing system of the present invention comprises:

[0021] A data processing terminal and at least one temperature collection terminal, wherein data is transmitted wirelessly between the temperature collection terminal and the data processing terminal.

[0022] Further, the temperature acquisition terminal includes: a temperature acquisition module, a signal conditioning module, an A / D conversion module, a first ZigBee module and a first processor module; the temperature acquisition module communicates with the signal conditioning module, the A / D conversion module and The signal input terminals of the processor module are connected, and the processor modul...

Embodiment 2

[0027] On the basis of Embodiment 1, the present invention also provides a method for testing the cooling performance of a quenching medium, including: wirelessly transmitting data between a temperature collection terminal and a data processing terminal.

[0028] Further, the temperature acquisition module in the temperature acquisition terminal is a nickel alloy metal probe, and the test method of the quenching medium cooling performance test method includes: the nickel alloy probe (specifically, a nickel alloy probe using an armored K-type thermocouple) Metal probe) is heated in the furnace to above the set temperature (for example 850°C), and then put into a certain volume of quenching medium (quenching oil) to be tested; when the temperature drops to the set temperature (850°C), the After the temperature change data of the recorded probe core is sent to the data processing terminal, the cooling characteristic curve and cooling rate characteristic curve of the quenching medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com