Multifunctional power line and manufacturing method thereof

A power cord and multi-functional technology, applied in the field of power cords, can solve problems such as increased replacement and maintenance of power cords, inconvenience in life and production, and easy hardening of the insulation layer, and achieves ingenious structural design, not easy to be damaged and worn by external forces, and hard to harden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

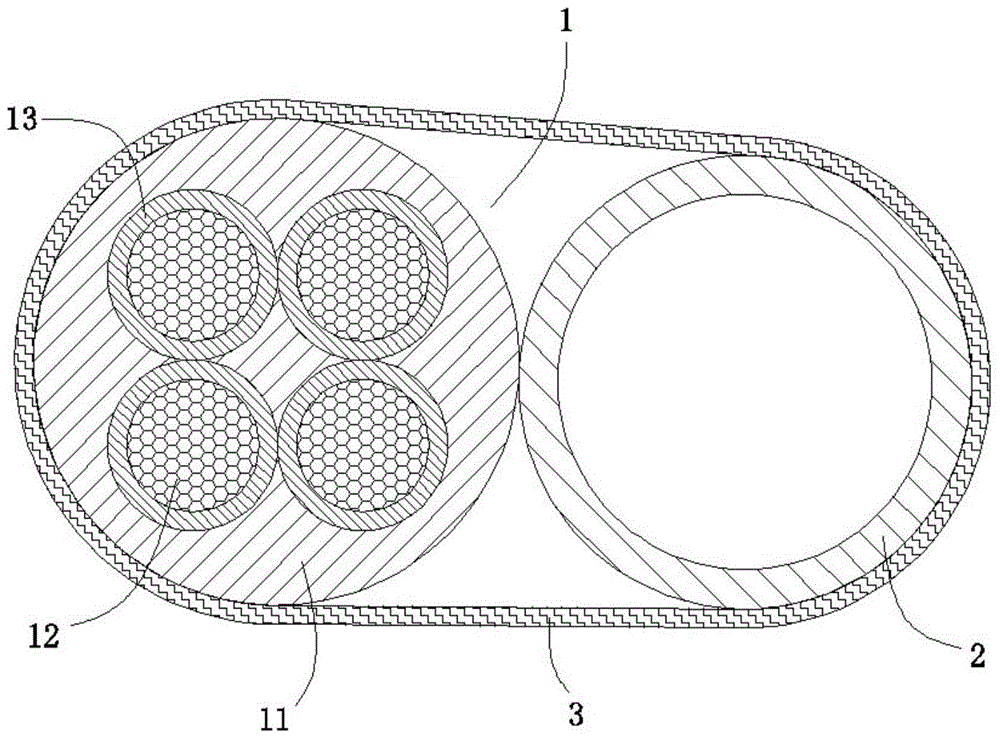

[0024] Example 1, see figure 1 , a multifunctional power cord provided in this embodiment is characterized in that it includes a conductor 1, a water guide body 2 and a fiber braided outer covering 3, and the conductor 1 is parallel to the water guide body 2 and forms a cable core side by side , the fiber braided outer cladding 3 is wrapped on the outer surface of the cable core.

[0025] The outline of the conductor 1 is circular. The conductor 1 includes an insulating rubber sheath 11 and four wires. The four wires are twisted together to form a core. The insulating rubber sheath 11 covers the wire core.

[0026] The insulating rubber sleeve 11 is composed of the following components by mass fraction: 50-70 parts of polyphenylene ether PPO, 30-50 parts of high-impact polystyrene HIPS, 40-60 parts of elastic filler, and 40-60 parts of polyphenylene ether 10-18 parts, flame retardant 30-50 parts, smoke suppressant 10-15 parts and antioxidant 1-3 parts.

[0027] The thickness...

Embodiment 2

[0037] Embodiment 2, which is basically the same as Embodiment 1, the difference is that the insulating rubber sleeve 11 is composed of the following components by mass fraction: 50 parts of polyphenylene ether PPO, 50 parts of high-impact polystyrene HIPS, 40 parts of elastic filler, 15 parts of polyphenylene ether, 40 parts of flame retardant, 10 parts of smoke suppressant and 3 parts of antioxidant.

Embodiment 3

[0038] Embodiment 3, which is basically the same as Embodiment 1, the difference is that the insulating rubber sleeve 11 is composed of the following components by mass fraction: 70 parts of polyphenylene ether PPO, 30 parts of high-impact polystyrene HIPS, 60 parts of elastic filler, 10 parts of polyphenylene ether, 50 parts of flame retardant, 15 parts of smoke suppressant and 2 parts of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com