Manufacturing method of copper-cladded ladder hole of circuit board ladder surface and application of manufacturing method

A manufacturing method and technology of stepped holes, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve problems such as poor control of step depth and corrosion of conductive metal, and achieve control uniformity, ensure consistency, and solve problems. The effect of abnormal signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

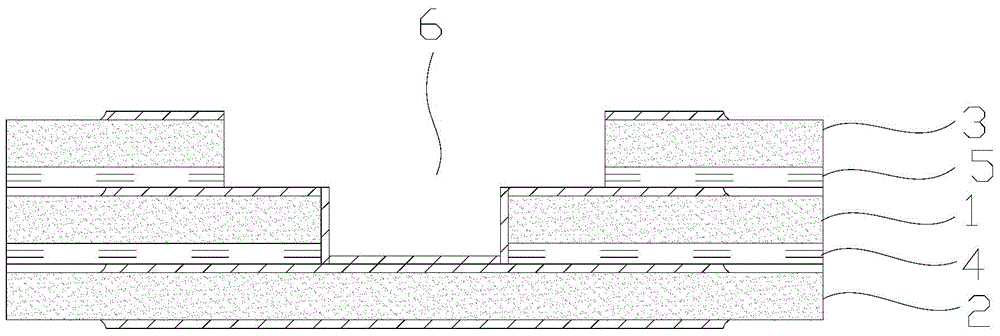

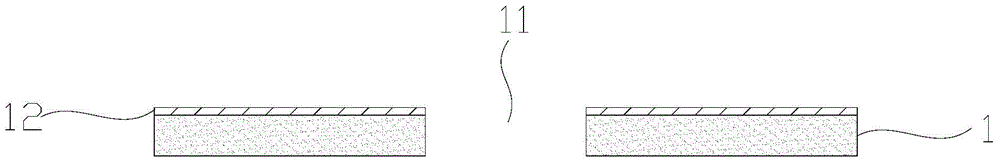

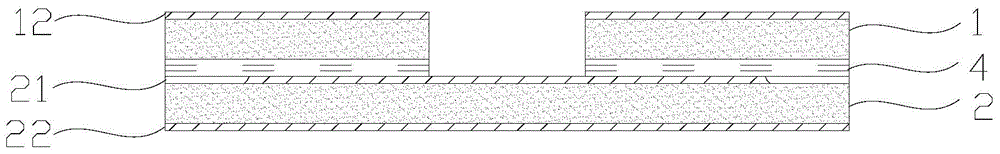

[0032] Such as figure 1 The circuit board with stepped holes covered with copper on the stepped surface includes a first core board 1, a second core board 2, a third core board 3, a first PP sheet 4, and a second PP sheet 5; the circuit board is provided with a ladder Hole 6. The wiring layer of this circuit board is false 6 layers, inner layer line width spacing: min 8 / 8miL, outer layer line width spacing: min 8 / 8miL, sheet material Tg: 150°C, outer layer copper layer thickness 1OZ. The thickness of the first core board 1 , the second core board 2 and the third core board 3 are all 2.0 mm; the fluidity of the first PP sheet and the second PP sheet is less than 0.06 mm.

[0033] A method for manufacturing a circuit board with stepped holes covered with copper on the stepped surface includes the following steps in sequence:

[0034] Drill out the first core board 1, the second core board 2, and the third core board 3 substrates; use the same drilling data to drill the periphe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap