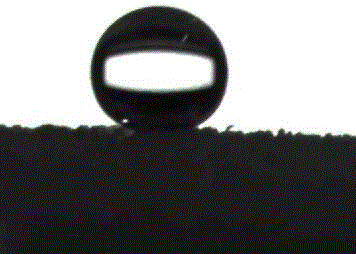

Method for preparing super-hydrophobic super-oleophilic porous material

A porous material, super lipophilic technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve the problems of long production cycle, complex preparation methods, etc., achieve short consumption time, simple and economical methods, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of superhydrophobic superlipophilic sponge, the steps are as follows:

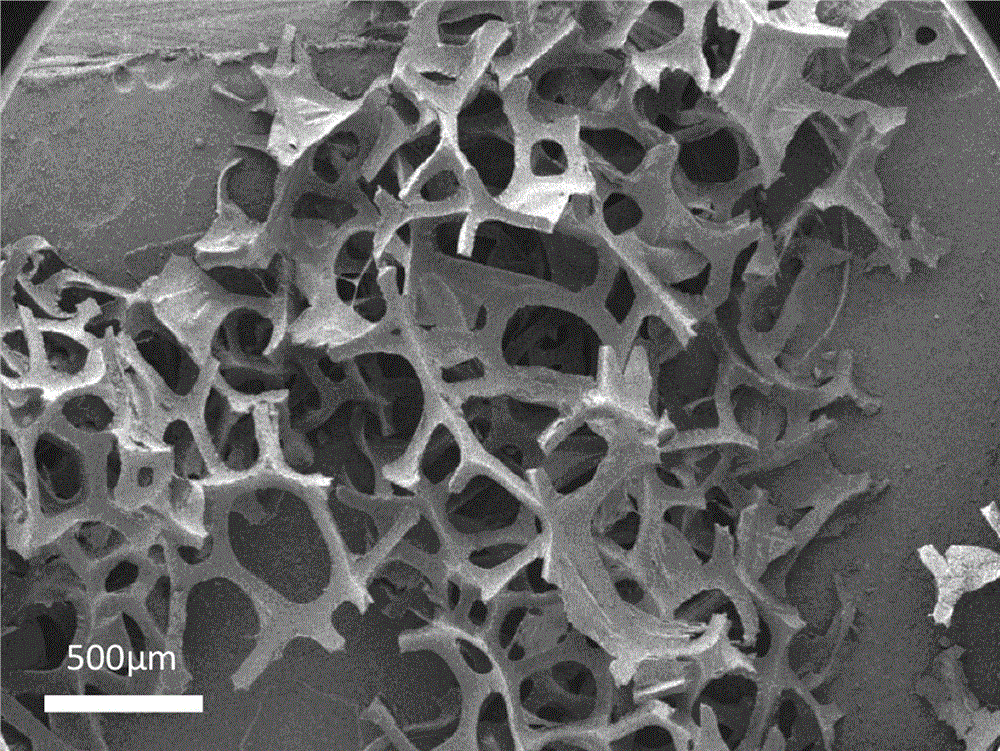

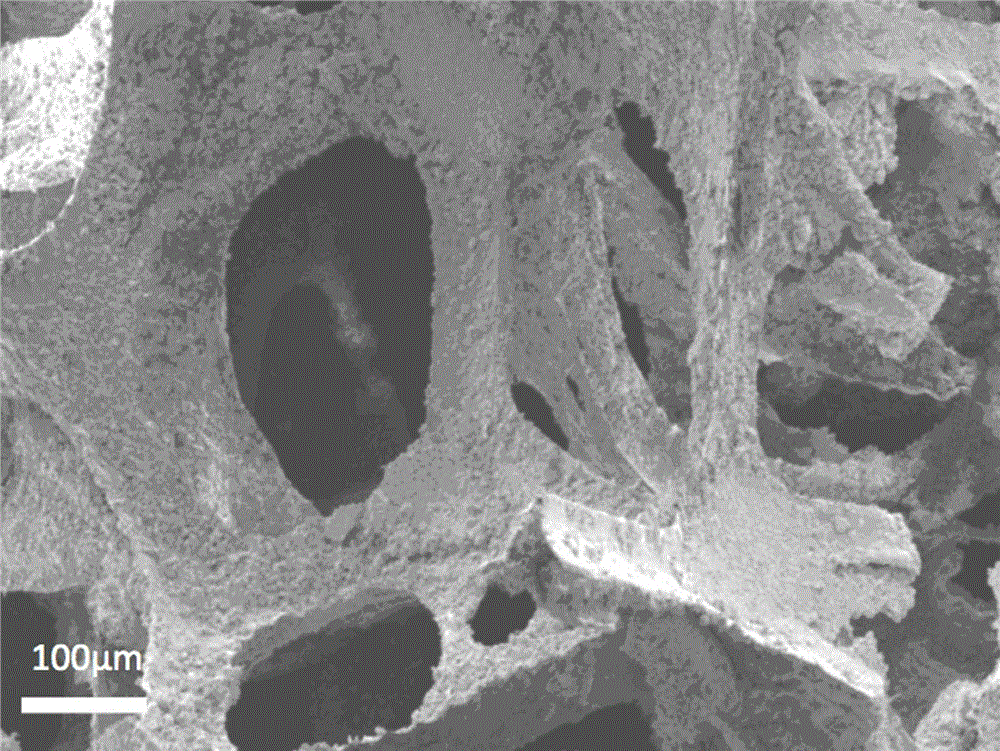

[0037] 1) Cleaning of polyurethane sponge: pour acetone into a beaker (acetone mass fraction ≥ 99.5%), and polyurethane sponge (its surface features such as figure 1 , the size is 10mm×10mm×0.3mm) into acetone, put the beaker into the ultrasonic device and ultrasonically clean it for 15-30 minutes, wash away the stains and grease impurities on the surface of the sponge, pour off the acetone, pour the acetone into the beaker again, Ultrasonic cleaning for 15 to 30 minutes, pour out acetone, pour in deionized water, stir, pour out deionized water to rinse off the acetone in the beaker and sponge, and finally dry the polyurethane sponge for later use;

[0038] 2) configuration of chromic acid lotion: measure 45ml deionized water, take by weighing 3g potassium dichromate and pour it into deionized water, then measure 5ml concentrated sulfuric acid (the mass fraction of sulfuric acid is 9...

Embodiment 2-6

[0042] The amount of concentrated sulfuric acid was adjusted to measure 6ml, 7ml, 8ml, 9ml, 10ml in turn, and the others were the same as in Example 1.

Embodiment 7-9

[0044] Soak the polyurethane sponge in the chromic acid lotion for 15s, 20s, and 40s in turn, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com