Low-l-acid high-b-acid catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, used in catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problem of the change of alumina acidity without specific characterization and testing, and improve the conversion rate of raw materials. , The effect of reducing the yield of low-carbon hydrocarbons and increasing the content of B acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

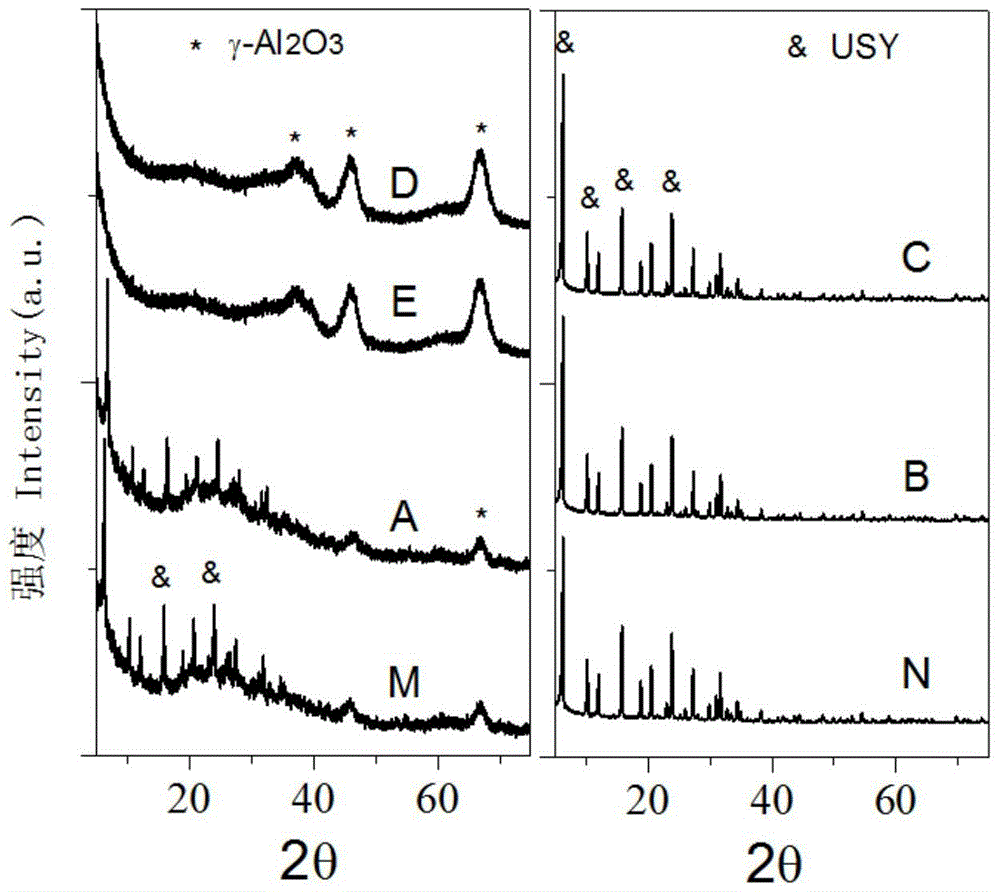

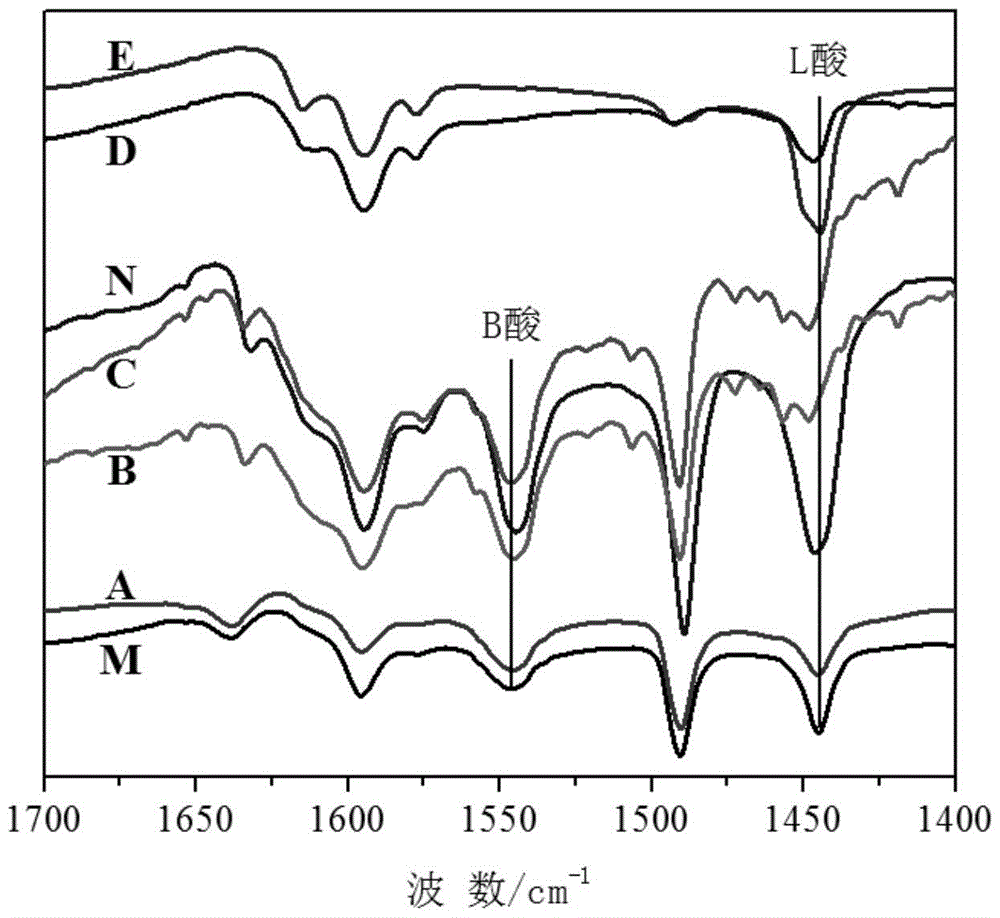

Embodiment 1

[0021] Take 20 grams of industrial catalytic cracking catalyst, marked as M, and add it into 50 ml of water and stir to make a slurry. Then, under the condition of 80°C water bath, 50ml of 0.65mol / L boric acid solution was added to obtain an acidified catalytic cracking catalyst suspension, and the reaction time was kept for 0.5h. 1.0 mol / L dilute nitric acid was added to the obtained mixture to adjust the pH to 3.0, and the reaction was continued for 24 hours under stirring in a water bath at 80°C. Finally, the reacted sample was suction-filtered, washed, dried at 110°C for 8 hours, and then calcined at 500°C for 4 hours to obtain a product marked as sample A.

Embodiment 2

[0023] Take 20 grams of Y-type molecular sieves, marked as N, add 50ml of water and stir for beating. Then, under the condition of 80°C water bath, 50ml of 0.65mol / L boric acid solution was added to obtain acidified pseudo-boehmite suspension, and the reaction time was 0.5h. Add 1.0 mol / L dilute nitric acid to the resulting mixture to adjust the pH to 3.0, and continue to react continuously for 24 h under the condition of stirring in a water bath at 80°C. Finally, the reacted sample was suction-filtered, washed, dried at 110° C. for 8 hours, and then calcined at 500° C. for 4 hours to obtain modified molecular sieve sample B.

Embodiment 3

[0025] Take 20 grams of Y-type molecular sieves, mark them as N, soak them in an aqueous solution containing 0.4 g of boric acid, and let them stand at room temperature for 12 hours. Then the obtained sample was dried at 80° C. for 8 h, and calcined at 500° C. for 4 h to obtain sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com