Automatic punching special machine for automotive glass guide rail

A technology for automotive glass and guide rails, which is applied in the field of auto parts processing, and can solve problems such as high equipment occupancy rate, failure to meet product quality and production management requirements, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

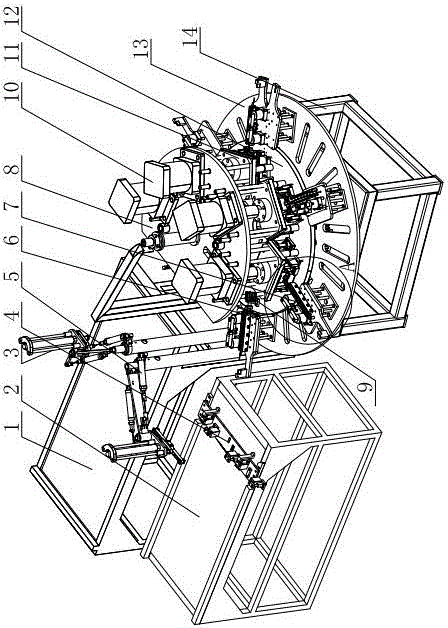

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

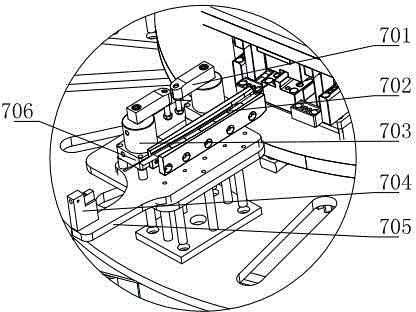

[0017] like figure 1 As shown, the auto glass guide rail automatic punching special machine of the present embodiment includes a placement frame 14, and an outer circular turntable 13 is installed on the placement frame 14 through a driving device. There are a number of evenly arranged oblong slots in the direction. The oblong slots are used for weight reduction and easy to rotate. There are mounting holes between the several oblong slots. The mounting holes are equipped with fixing seats. 6. The lower end of the fixed seat 6 is connected to the lifting cylinder, which is used to put the parts into and out of the mold 11 in the up and down direction; the upper surface of the fixed seat 6 is installed with the carrier 7; There are many sets of molds 11 installed in the direction, and the hydraulic cylinder 10 is fixed by the mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com