Positioning devices for the precise manufacture of complex automotive parts

A technology for auto parts and positioning devices, applied in auxiliary devices, vehicle parts, manufacturing tools, etc., can solve the problems of low positioning strength, poor welding effect, uneven force, etc., and achieve firm positioning, high precision, and reduced operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

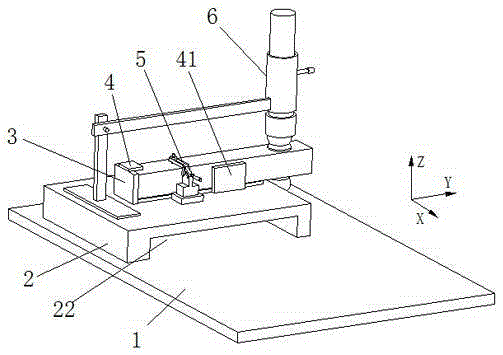

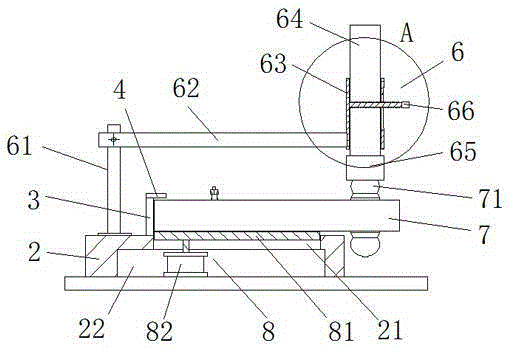

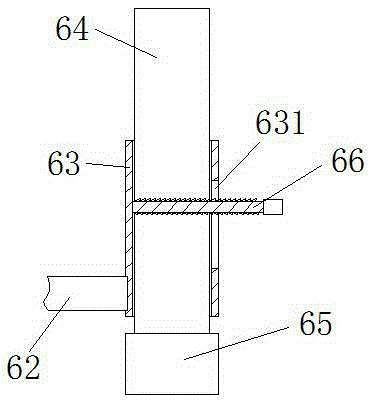

[0026] Example 1, such as Figure 1-2 As shown, the auto parts include a main rod 7 and a connecting ball 71 . A positioning device for precise manufacturing of complex auto parts, including a platform 1, on which a base 2 is arranged, the front and rear direction of the base 2 is defined as the X-axis direction, and the left-right direction of the base 2 is defined as the Y-axis direction, The up and down direction of the base 2 is defined as the Z-axis direction.

[0027] The base 2 is provided with a fixed plate 3 for limiting the Y-axis direction at one end of the accessory. The fixed plate 3 can be set according to the end face of the main body rod 7. For example, when the end face of the main body rod 7 is an inclined surface, the fixed plate 3 is also set as Corresponding tilt angle. The upper end of the fixing plate 3 is welded with a baffle plate 4 used to limit the Z-axis direction of one end of the accessory. The base 2 is provided with a side baffle 41 used to li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com