Method and device for magnetic grinding of inner annular groove and outer annular groove of sealing sleeve part

A technology of magnetic grinding and sealing sleeve, which is applied in the field of grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with examples in conjunction with the accompanying drawings.

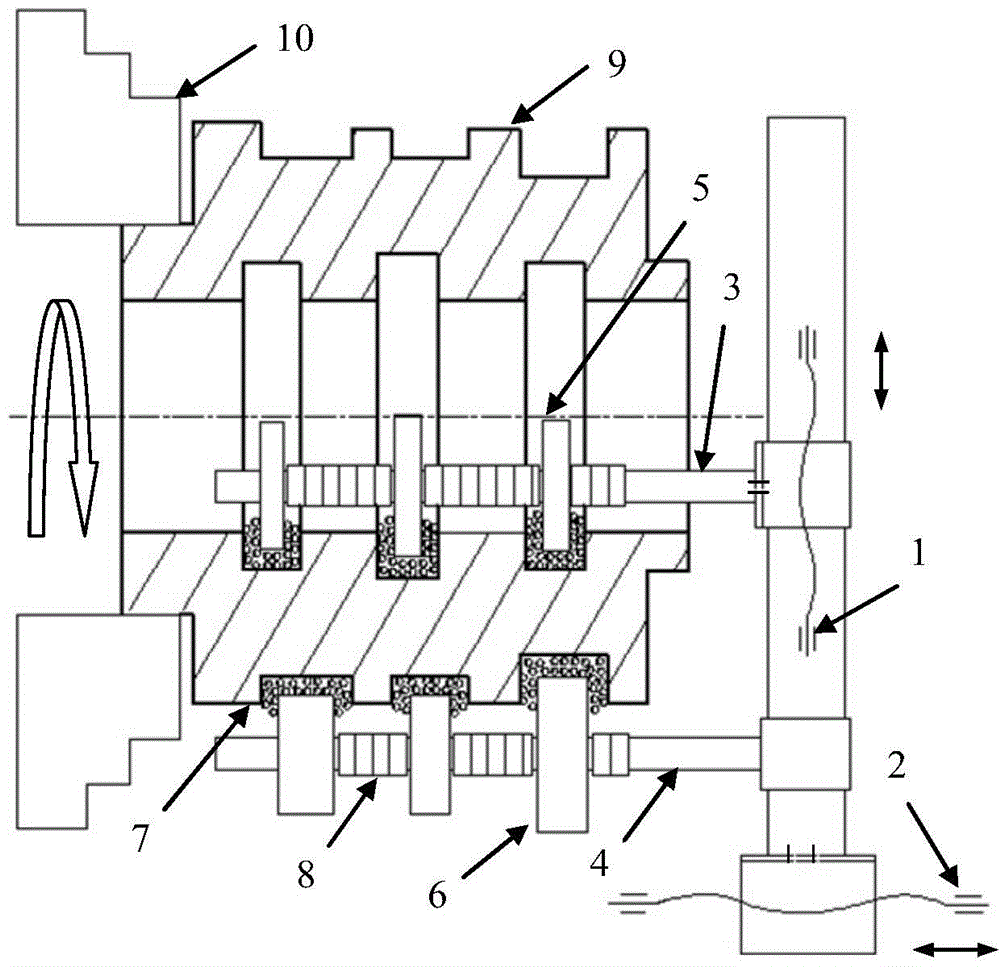

[0022] A method and device for magnetically grinding the inner and outer ring grooves of a sealing sleeve part, wherein the inner and outer ring grooves of the sealing sleeve part are taken as an example of the inner and outer grooves of a piston sleeve, and the device is as follows figure 1 Shown, in conjunction with device description, the steps of the method are as follows:

[0023] 1. Use an ultrasonic cleaning machine, add a small amount of cleaning agent to clean the workpiece, remove the surface stains on the piston sleeve, and dry it;

[0024] 2. Fix the piston sleeve 9 on the spindle chuck 10, install the arc-shaped inner magnetic pole 5 and outer magnetic pole 6 suitable for the diameter of the ring groove of the piston sleeve on the inner magnetic pole fixing rod 3 and the outer magnetic pole fixing rod 4 of the grinding device Above, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com