Manufacturing method for universal bending glued bamboo laminate board

A technology of universal bending and manufacturing method, which is applied in other directions such as plywood/plywood utensils, manufacturing tools, and joining of wooden veneers to achieve good toughness, high quality, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

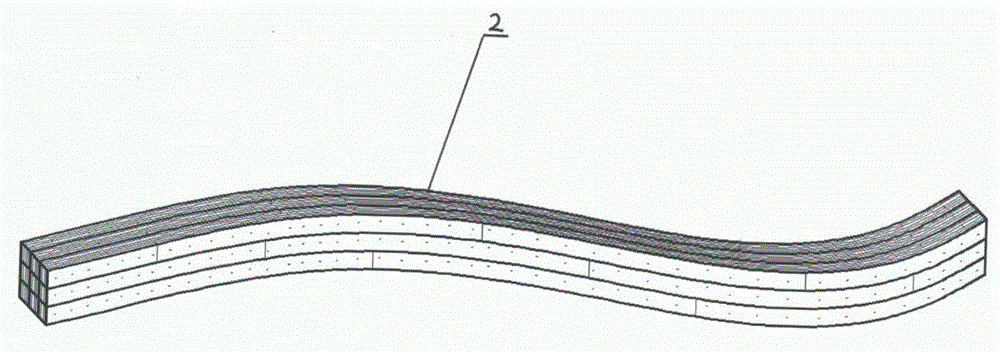

[0037] A kind of manufacturing method of universal bending glued bamboo laminate

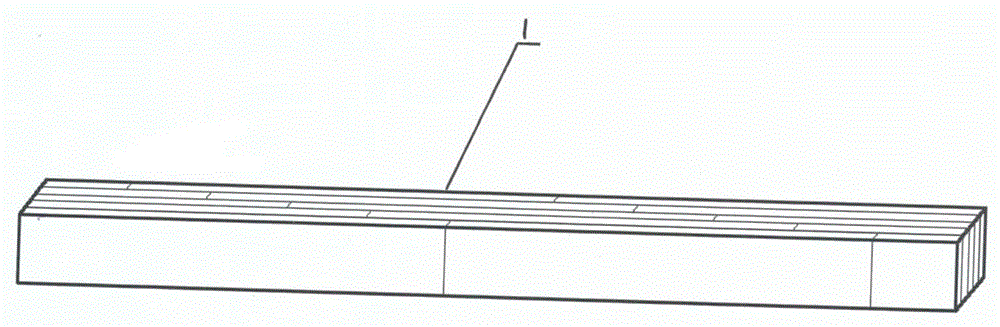

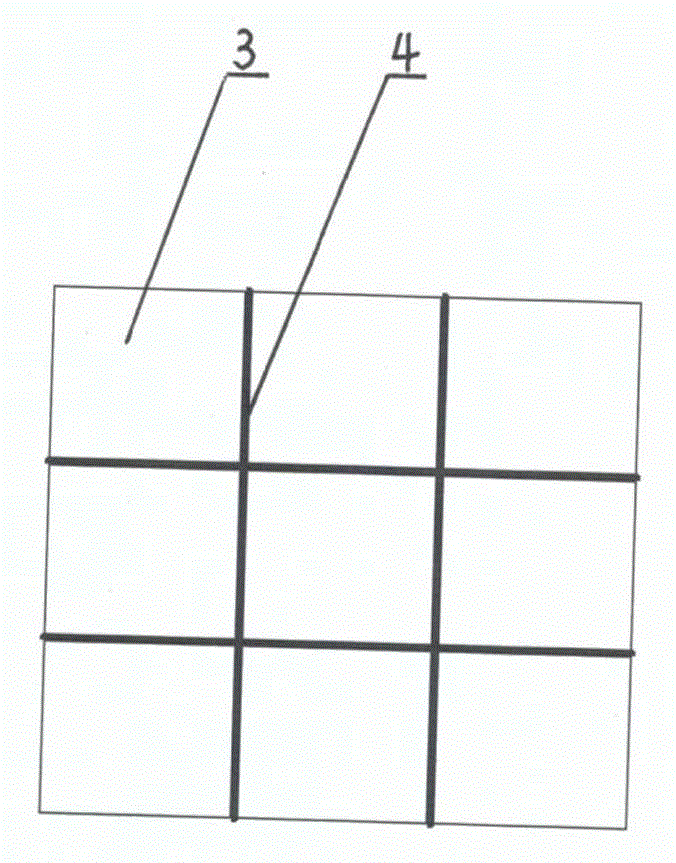

[0038] like Figure 1 to Figure 5 As shown, (1) Bamboo chip sorting, requirements: the section size is stable, there is no obvious defect, and the density difference is small.

[0039] The size and specification of the bamboo slices, the length of the bamboo slices is 2.0m, and the thickness and width series of the bamboo slices are shown in Table 1.

[0040] Table 1 Thickness and width series of bamboo slices

[0041] Bamboo thickness mm 4 5 6 Bamboo width mm 18 20 20

[0042] (2) Fixed-length processing of bamboo slices, in order to make the step staggered seams regularly distributed on the bamboo plywood, the selected bamboo slices need to be fixed-length processing, and the bamboo strips are cut into 2.0 m with a double-end saw for use.

[0043] (3) Bamboo chips are dried. A fast microwave drying oven is used to dry the selected bamboo chips with similar densities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com