Preparation of polypropylene / organic montmorillonite nanometer composite material

A technology of nanocomposite materials and organic montmorillonite, which is applied in the field of preparing polypropylene composite materials, can solve problems such as unsatisfactory mechanical properties and unsatisfactory strengthening and toughening effects, achieve good industrialization prospects, improve modulus and toughness, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples are to further illustrate the present invention, but not to limit the scope of the present invention.

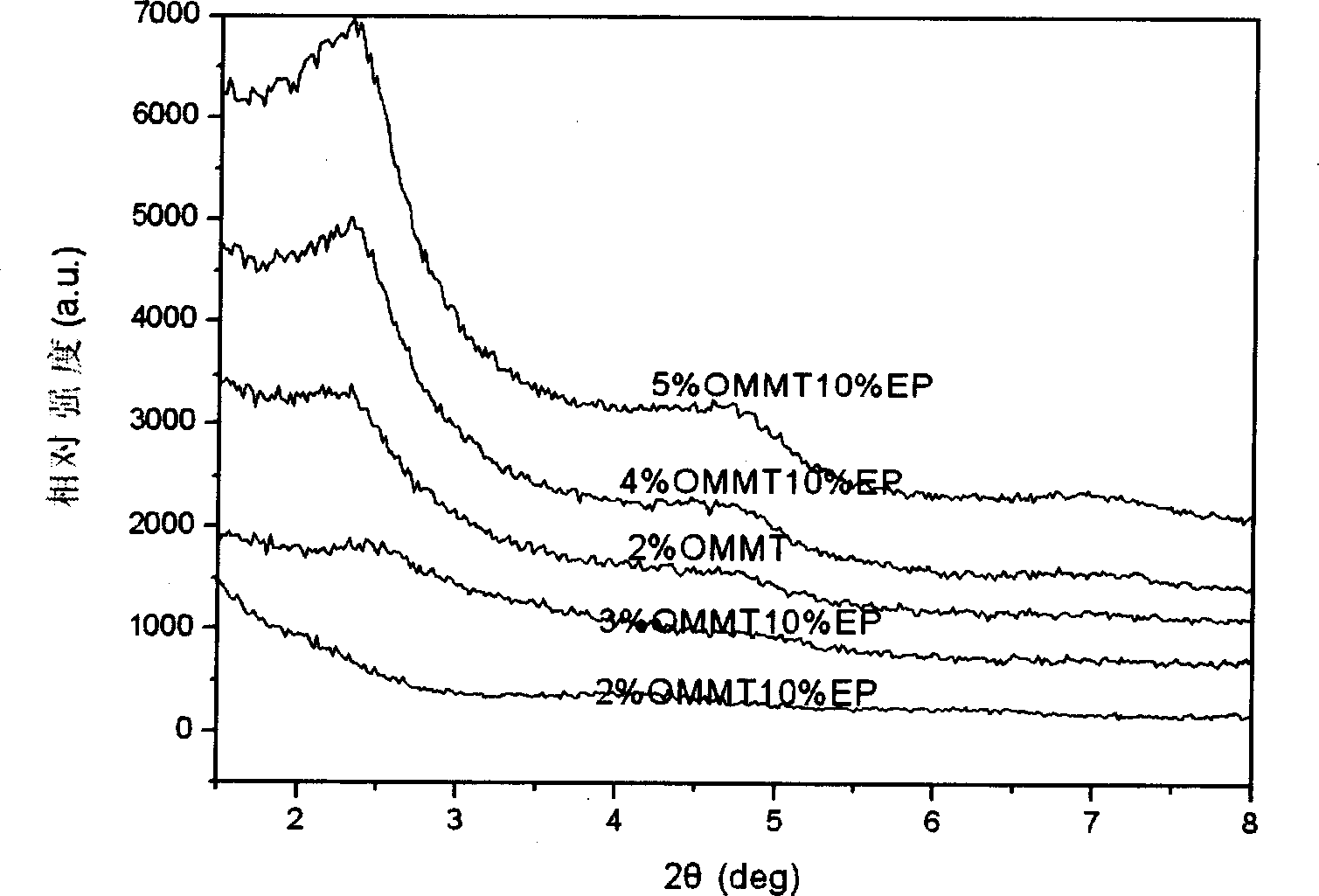

[0014] Embodiments 1 to 4: According to the formula in Table-1, at a temperature of 200°C, add polypropylene (F401, melt index 2.3g / 10min, Yangzi Petrochemical Company), maleic anhydride in a twin-screw extruder Grafted polypropylene (MAH-g-PP, grafting rate 1%, Shanghai Rizhisheng Plastic Co., Ltd.), epoxy resin (bisphenol A diglycidyl ether type, brand: E-12 epoxy equivalent 810g / eq, Shanghai Resin T Co., Ltd.), imidazole (EMI, analytically pure, Shanghai Chemical Reagent Factory), organic montmorillonite (bis(2-hydroxyethyl) methyl tallow base quaternary ammonium salt modification, DK2 type, Zhejiang Feng Rainbow Clay Co., Ltd.) extrusion granulation, screw speed 110 rpm. The epoxy resin cures during the extrusion process and is inserted into the organic montmorillonite sheets under high shear forces. The prepared composite material partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com