Aluminum alloy formwork device for outer wall heat preservation

A technology of aluminum alloy formwork and external wall insulation, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of the flatness of external walls It is difficult to guarantee, the installation time of the insulation board is long, and the workload of the construction personnel is heavy, so as to save the drying time, reduce the installation cost and save the effect of anchors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

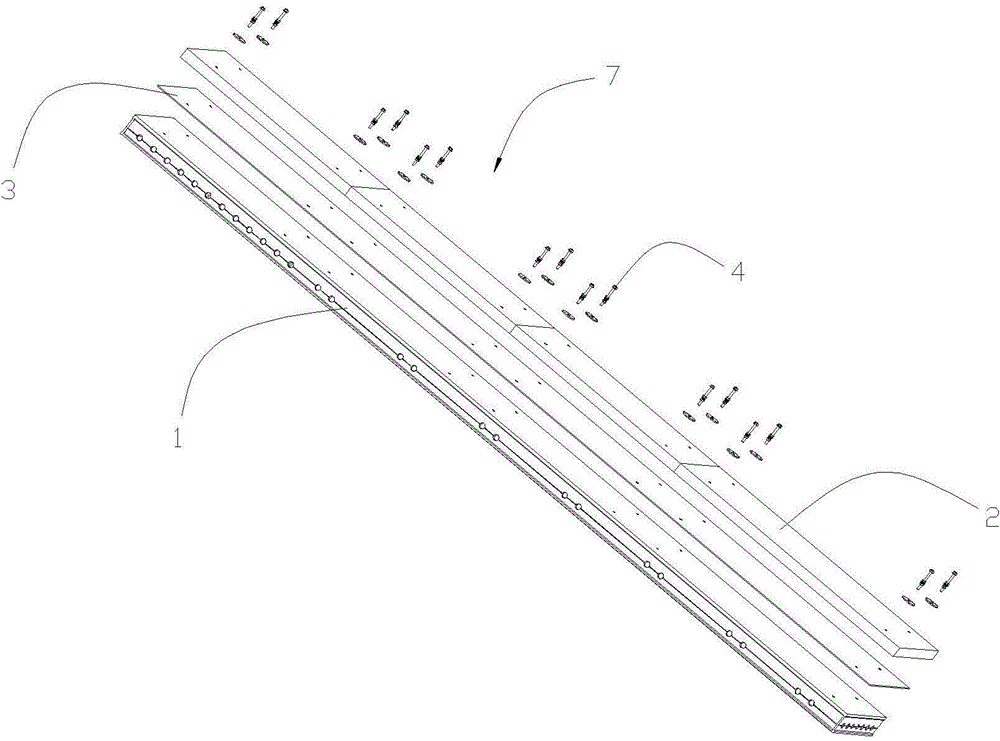

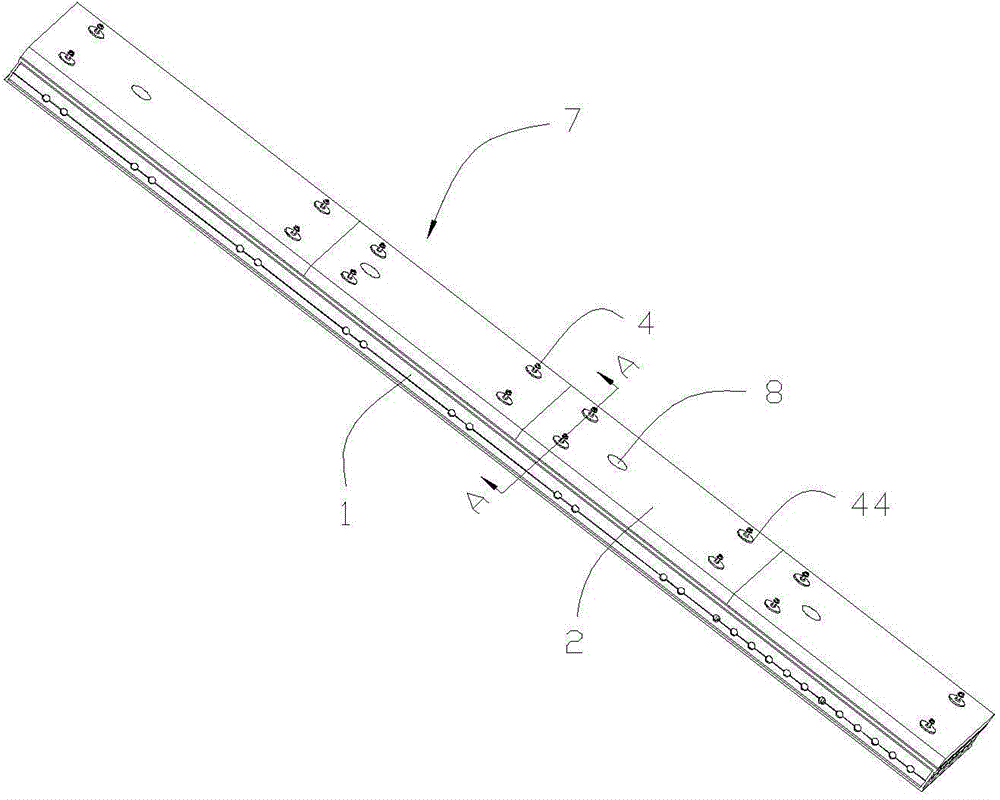

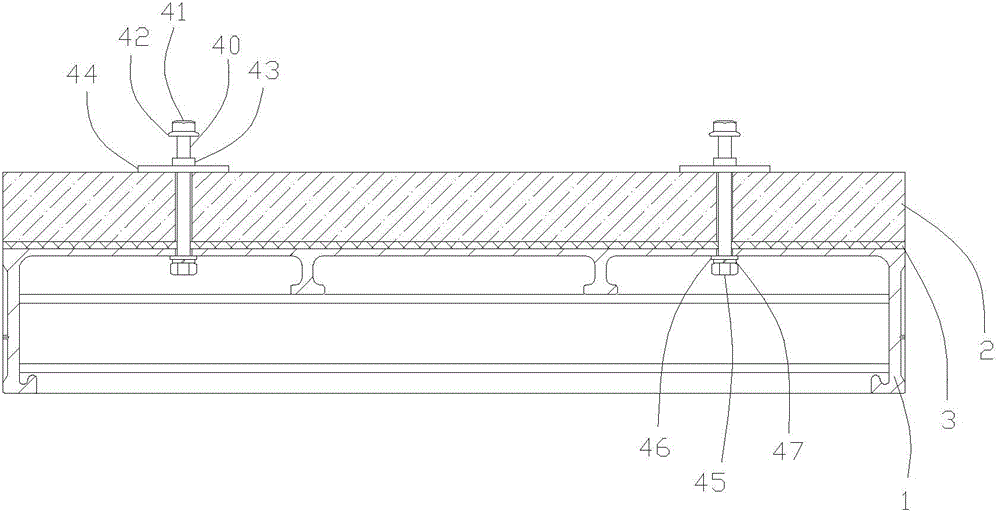

[0025] Such as Figure 1-Figure 4 As shown, an aluminum alloy formwork device 7 for exterior wall insulation of the present invention includes an exterior wall formwork 1, an insulation board 2 located inside the exterior wall formwork 1, and several connecting bolts 4 for fixing the exterior wall formwork 1 and the insulation board 2, Each connecting bolt 4 includes a connecting screw 40 extending from the side of the insulation board 2 away from the exterior wall formwork 1 and passing through the insulation board 2 and the exterior wall formwork 1 in sequence, and a first nut 41 sleeved on the connection screw 40 , the third nut 45 and the second nut 43 between the first nut 41 and the third nut 45, the second nut 43 is located on the side of the insulation board 2 away from the exterior wall formwork 1, and the third nut 45 is located on the exterio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com