Measuring device, measuring method and application of material micro-area conductance and thermoelectric properties

A measuring method and technology of measuring device, which are applied in the direction of measuring device, measuring electrical variable, measuring resistance/reactance/impedance, etc., and can solve the problems of inability to measure the conductance and thermoelectric potential of material in micro-area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

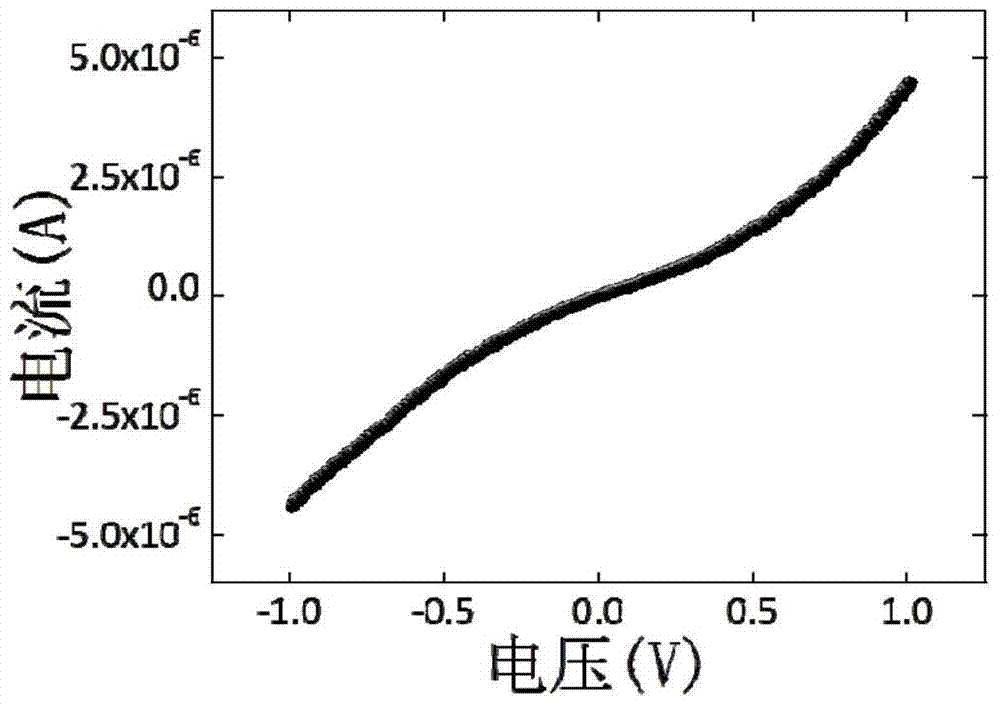

[0038] Embodiment 1: The conductance of film sample is measured

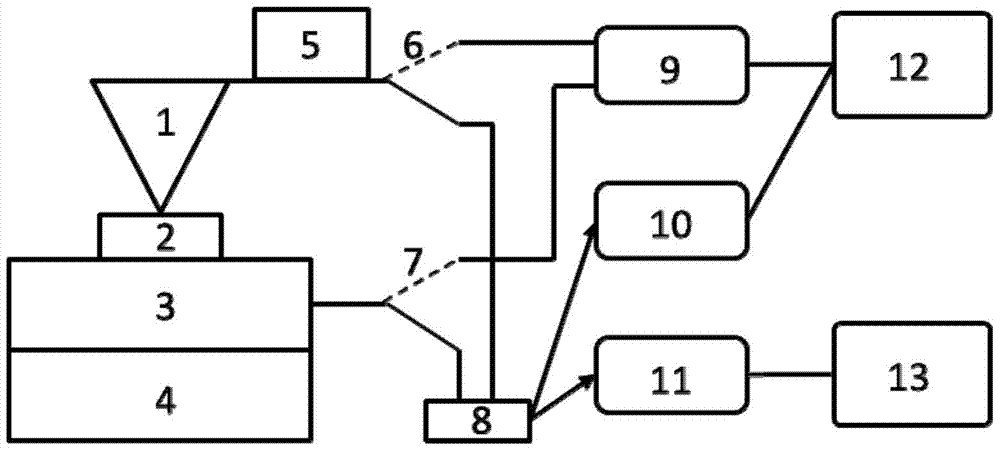

[0039] Such as figure 1As described above, the thin film sample 2 is deposited on the conductive metal substrate 3, the conductive metal substrate 3 is adhered to the temperature control sample stage 4, the conductive probe 1 is in contact with the surface of the thin film sample 2 under the control of the atomic force microscope controller 11, and the thin film sample 2 The conductive metal base 3 below forms two electrodes, and the host computer 12 controls the first static contact of the first relay 6 and the second relay 7 to be in a closed state so that the conductive probe 1 and the conductive metal base 3 are connected to the programmable current source meter 9 connected, the host 12 controls the program-controlled current source meter 9 to output a series of voltages on the conductive probe 1 and the conductive metal substrate 3, and measure the current value returned from the conductive probe 1 and the ...

Embodiment 2

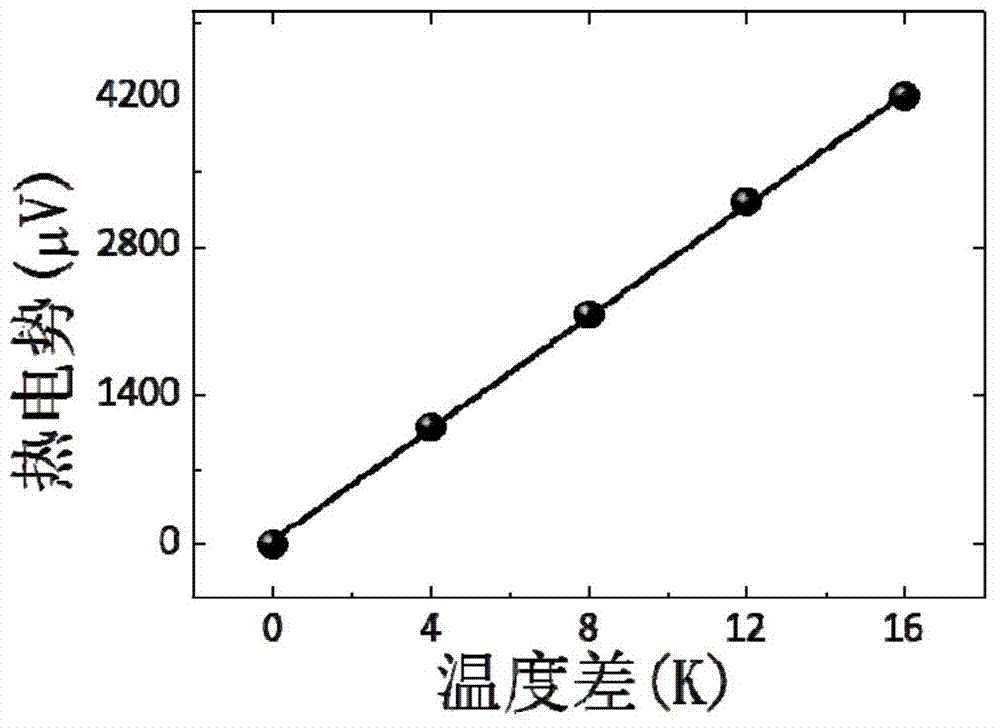

[0040] Embodiment 2: measure the thermoelectric potential of film sample

[0041] The thin film sample 2 is deposited on the conductive metal substrate 3, the conductive metal substrate 3 is adhered to the temperature control sample stage 4, the sample 2 to be tested is heated to a known temperature higher than room temperature through the temperature control sample stage 4, and the conductive probe 1 Contact with the film sample 2 surface under the control of the atomic force microscope controller 11, form two electrodes with the conductive metal substrate 3 below the film sample 2, maintain the conductive probe 1 at room temperature through the high thermal conductivity cold storage 5, and conduct the conductive probe 1 A temperature gradient of a micro-region will be generated nearby, and this temperature gradient forms a potential difference between the conductive metal substrate 3 and the conductive probe 1, and the host computer 12 controls the second static contact of th...

Embodiment 3

[0042] Example 3: Simultaneous imaging of thermoelectric potential and sample morphology of thin film samples

[0043] The thin film sample 2 is deposited on the conductive metal substrate 3, the conductive metal substrate 3 is adhered to the temperature control sample stage 4, the sample 2 to be tested is heated to a known temperature higher than room temperature through the temperature control sample stage 4, and the conductive probe 1 Contact with the film sample 2 surface under the control of the atomic force microscope controller 11, form two electrodes with the conductive metal substrate 3 below the film sample 2, maintain the conductive probe 1 at room temperature through the high thermal conductivity cold storage 5, and conduct the conductive probe 1 A temperature gradient of a micro-region will be generated nearby, and this temperature gradient forms a potential difference between the conductive metal substrate 3 and the conductive probe 1, and the host computer 12 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com