Flexible, stretchable and deformable curved surface optical lithography template as well as optical lithography method and device

A flexible template, flexible technology, applied in the field of nano-processing, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

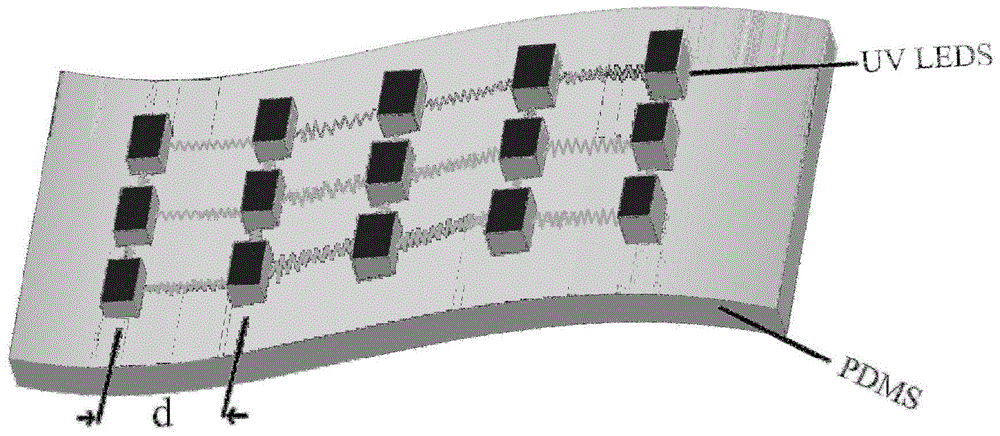

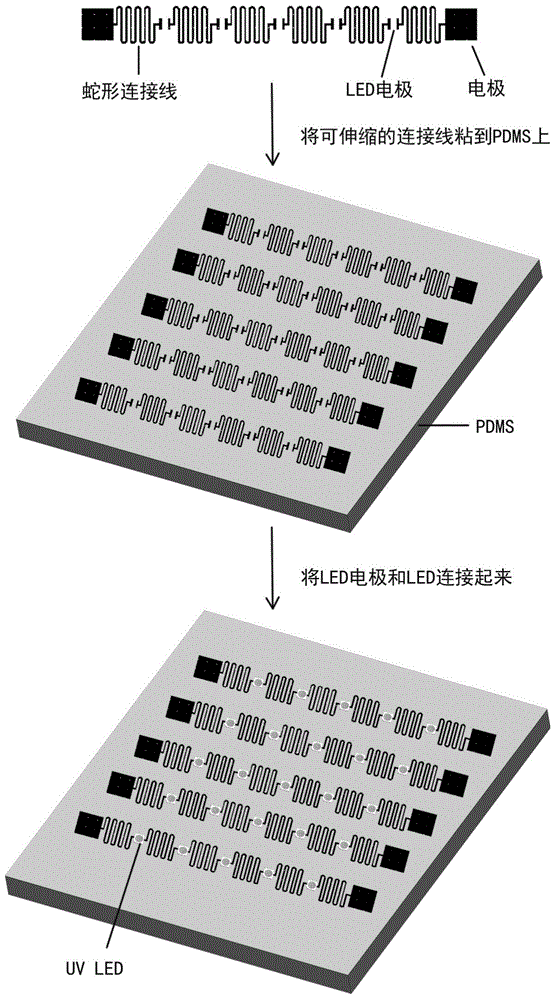

[0030] The technical scheme of the present invention is: making a stretchable flexible photolithography mask; making a flexible ultraviolet light-emitting diode (LED) panel as a light source for exposure; tightly attaching the flexible and stretchable template to the On the substrate coated with photoresist (it can be flat or complex curved surface); attach the flexible LED panel tightly to the flexible template; according to the appropriate dose and corresponding exposure time, turn on the LED to expose the photoresist; remove the flexible LED panel; remove the mask; this exposure is complete. Development and subsequent processing can then be performed. Mask sheets and flexible LED panels can be used multiple times.

[0031] The steps in the technical solution are described in detail below

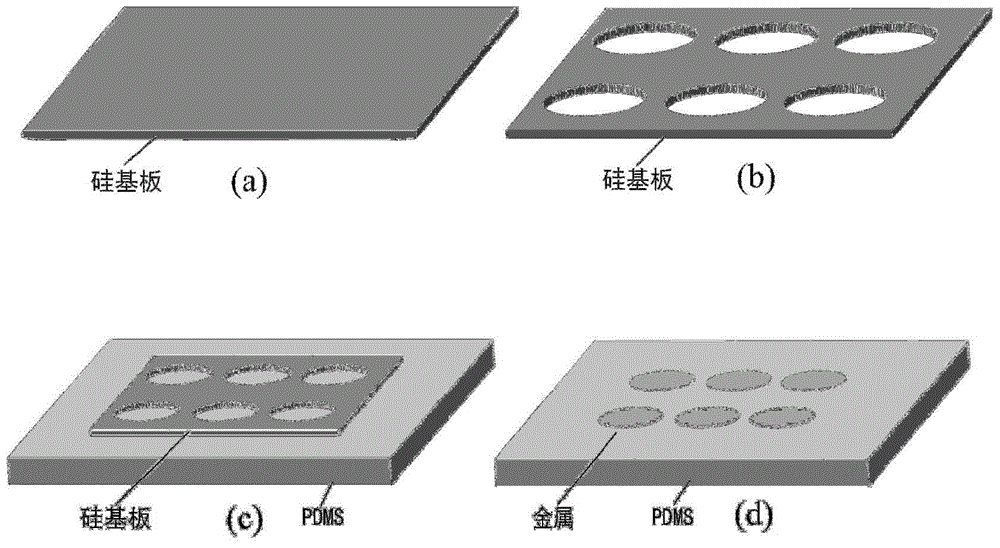

[0032] (1) Fabricate a stretchable flexible photolithography mask

[0033] The stretchable flexible mask can be made of low Young's modulus silicone, such as PDMS (Polydimethylsiloxan)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com