Method for assembling split stator core and assembly tool used thereby

A technology for stator iron core and assembly tooling, which is applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of inability to meet the high precision requirements of cylindricity size, iron core deformation, and large residual stress in the stator iron core, so as to achieve sufficient heat. The effect of transfer diffusion, small output heat, and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

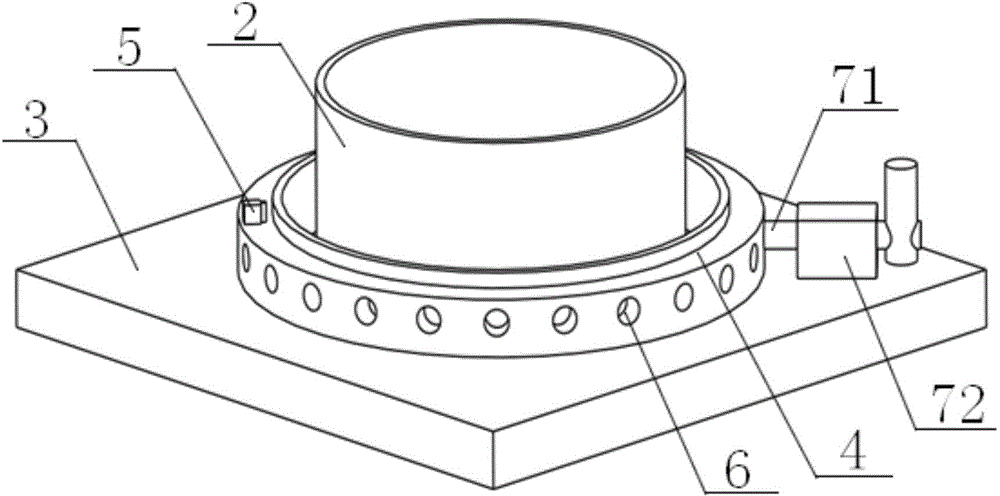

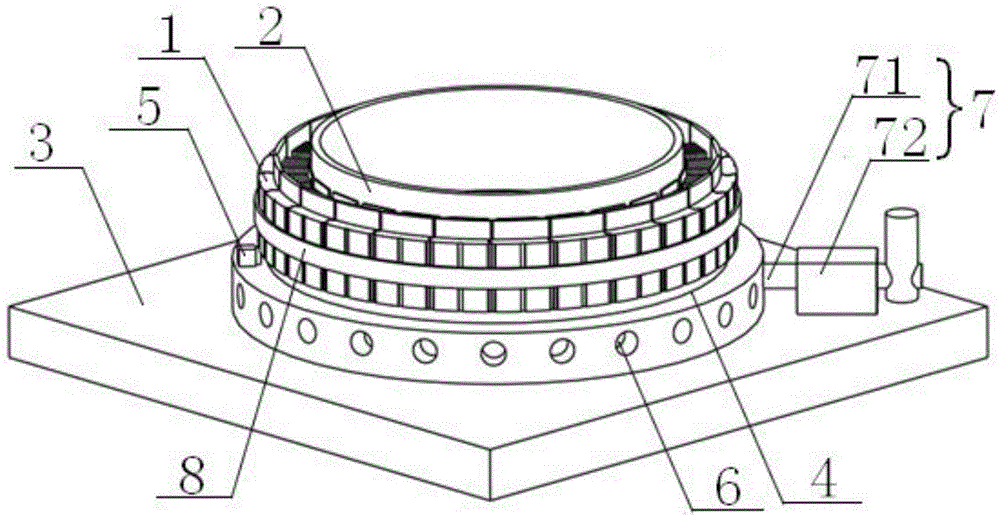

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

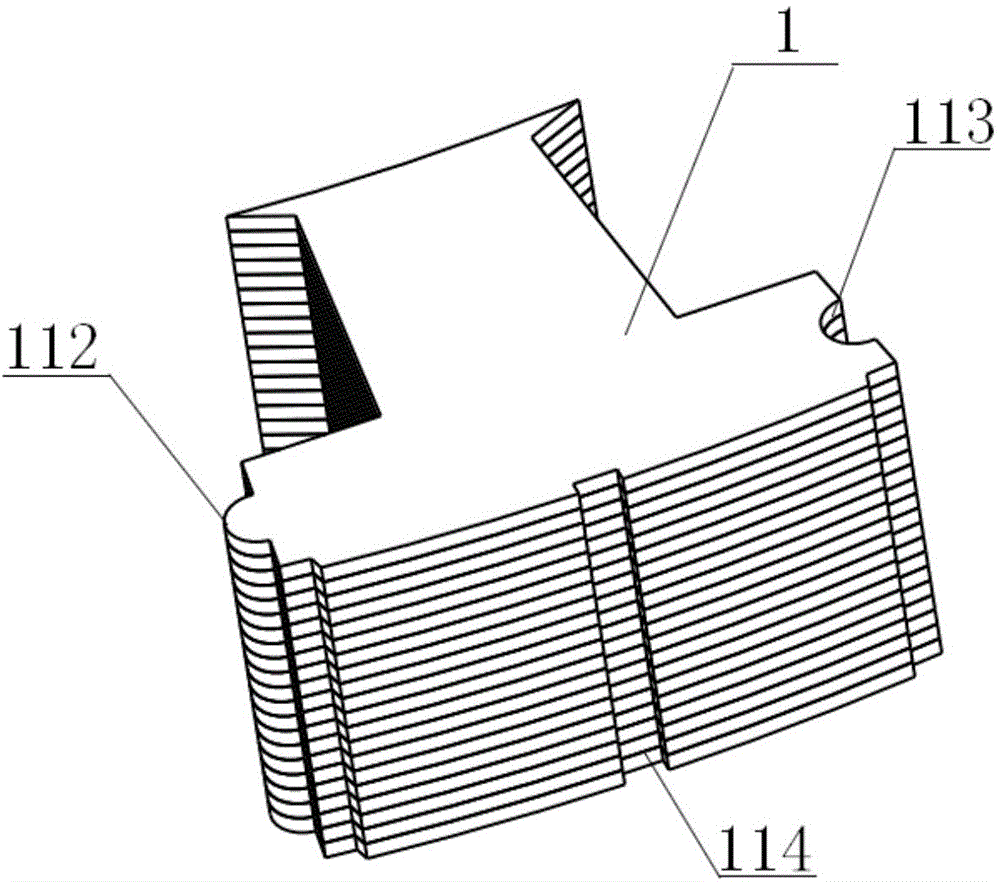

[0034] The assembly method (or called rounding method) and assembly tooling described in the present invention are suitable for segmented (also known as split type, block type, etc.) stator cores, which include several core units 1 , In this embodiment, taking 24 iron core units as an example, the iron core unit 1 is composed of a plurality of stamped sheets with the same shape and size.

[0035] Such as figure 1 As shown, one side connection end of each iron core unit 1 is formed with a connection protrusion 112 (the shape can be semicircle, semi-ellipse, dovetail or square, etc.), and the other side connection end is formed with a connection protrusion 112 is fitted with a connection recess 113 . In addition, a positioning groove 114 is formed on the outer surface of each core unit 1 .

[0036] When assembling the iron core unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com