Flat linear vibration motor

A linear vibration, flat technology, applied in electrical components, electromechanical devices, etc., can solve the problems of fatigue, failure elasticity, affecting motor performance and service life, etc., to improve performance, avoid the influence of motor performance and life, and improve magnetic utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

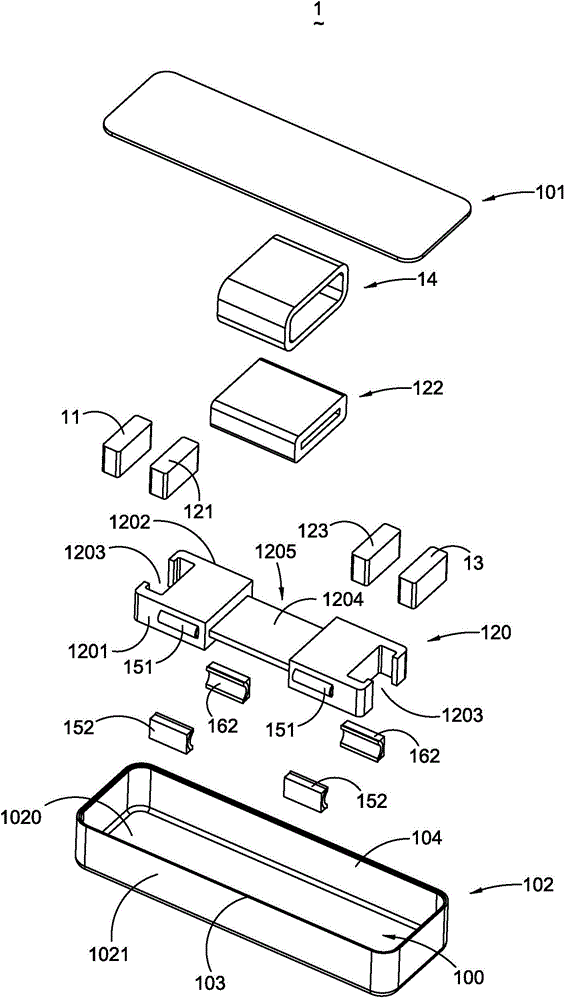

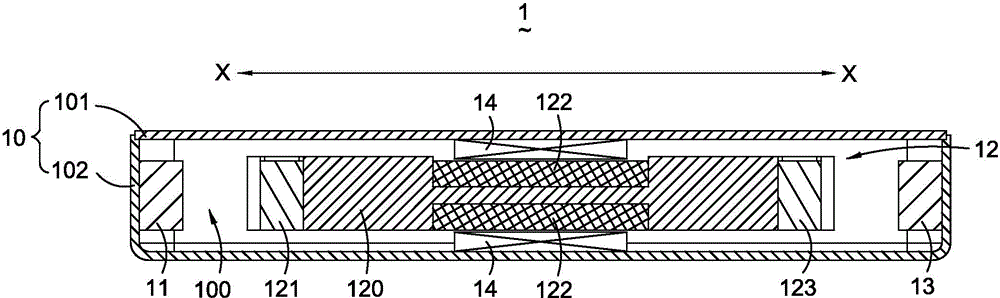

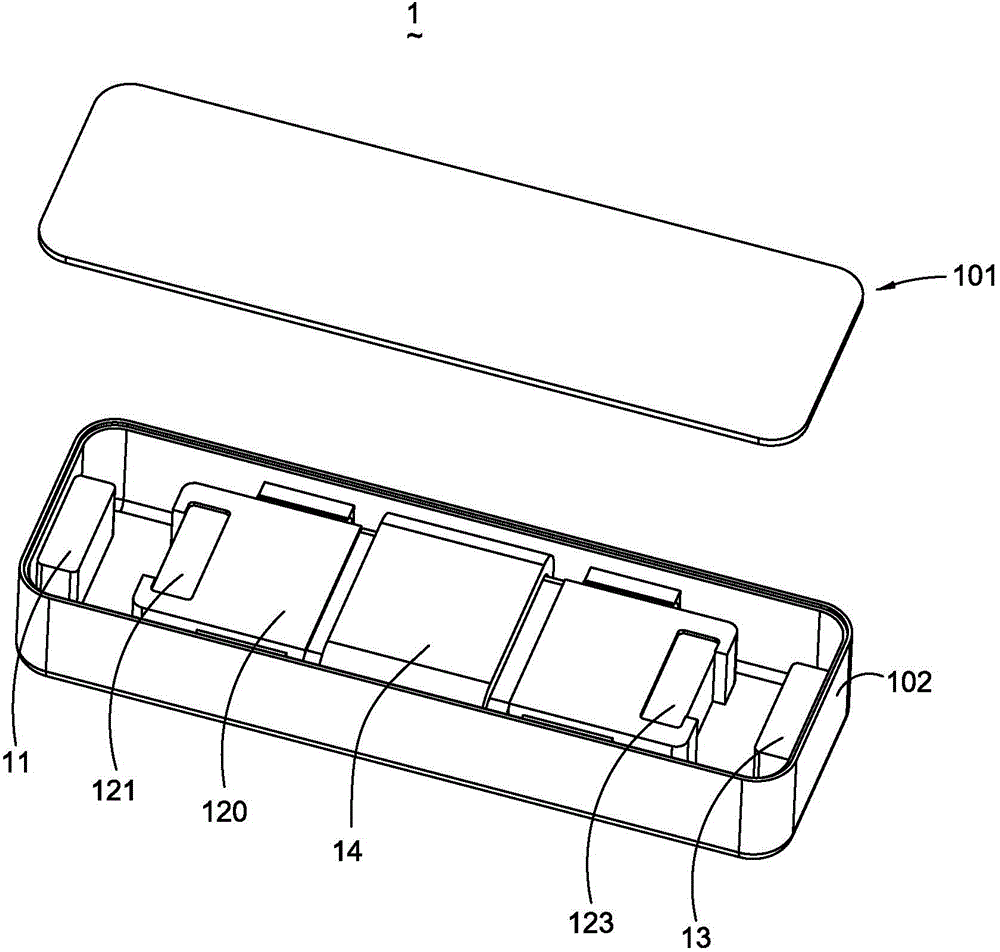

[0022] Such as figure 1 , 2 As shown in and 3, it is a flat linear vibration motor 1 provided by the present invention, which includes an elongated housing 10 with an accommodating space 100 inside, a housing fixed to the housing 10 accommodated in the accommodating space 100 The first magnet 11, the vibration unit 12 suspended in the housing 10, and the second magnet 13 fixed to the housing 10, wherein the first magnet 11, the vibration unit 12 and the second magnet The steel 13 is arranged in sequence along the vibration direction X-X of the vibration unit 12 .

[0023] The casing 10 includes an upper casing 101 and a lower casing 102 that cooperates with the upper casing 101 to form the accommodation space 100 , and the lower casing 102 includes a bottom wall 1020 and a side wall 1021 extending from the bottom wall 1020 , specifically as figure 1 shown. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com