Friction type two-way rectilinear motion micromotor driven by single pair of actuators and preparation method of micromotor

A technology of linear motion and actuator, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motor, generator/motor, electrical components, etc., can solve problems such as complex structure, achieve high output efficiency, easy Controlled, process-compatible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

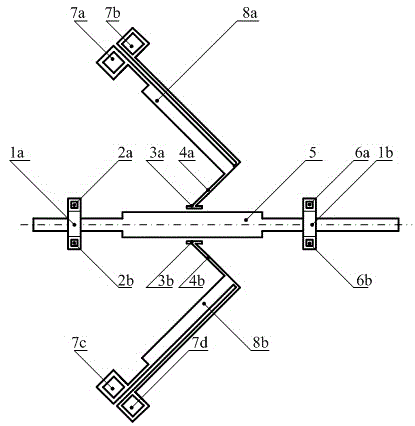

[0024] see figure 1 , a friction type two-way linear motion micromotor driven by a single pair of actuators, comprising an actuating unit and a slide bar 5, characterized in that: the actuating unit consists of cold and hot arm electrothermal actuators 8a, 8b, a drive rod 4a, 4b and driving heads 3a, 3b; one end of the hot and cold arm electrothermal actuator 8a, 8b is fixed on the silicon substrate through the anchor point 7a, 7b, 7c, 7d, and the other end is connected with the driving rod 4a, 4b, The ends of the drive rods 4a, 4b are square drive heads 3a, 3b, there is a gap between the drive heads 3a, 3b and the slide bar 5, the slide bar 5 is a floating bar, constrained by two longitudinal restraint covers 1a, 1b, The longitudinal restraint covers 1a, 1b are fixed on the silicon substrate through the anchor points 2a, 2b, 6a, 6b, and the anchor points 7a, 7b, 7c, 7d of the electrothermal actuators 8a, 8b of the cold and hot arms are also micromotors. power supply electrod...

Embodiment 2

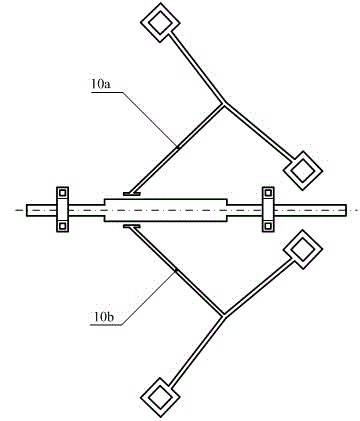

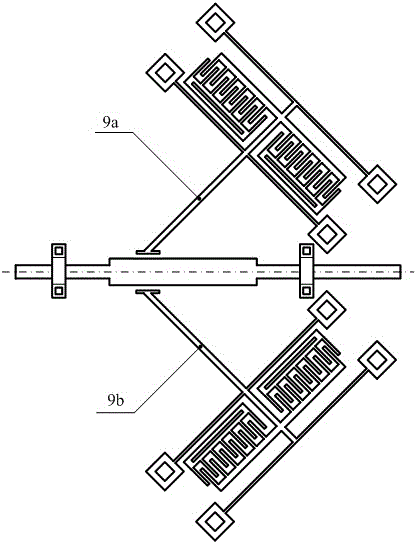

[0026] see figure 2 with image 3 , this embodiment is basically the same as Embodiment 1, and the special features are as follows: the electrothermal actuators of the cold and hot arms in the actuating unit are replaced by V-shaped electrothermal actuators and electrostatic comb actuators.

Embodiment 3

[0028] see Figure 4 , this embodiment is basically the same as Embodiment 1, and the special features are as follows: the actuating unit is only arranged on one side of the slide bar 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com