Pumping concrete equipment management control method and pumping concrete equipment management control device

A technology for pumping concrete and equipment management, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of misoperation safety, signal interference, hidden dangers, etc., to improve operability, improve safety, expand strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

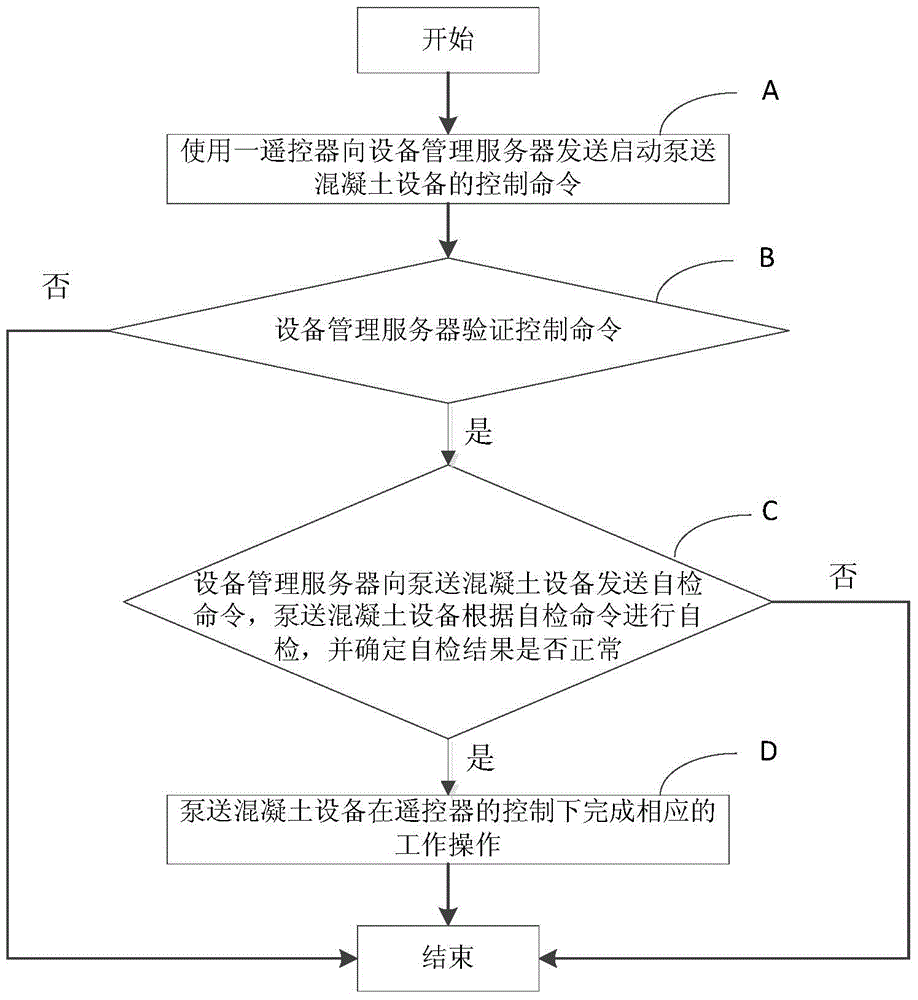

[0049] Such as figure 1 Shown is a flow chart of a management and control method for pumping concrete equipment provided by a preferred embodiment of the present invention. The method specifically includes the following steps:

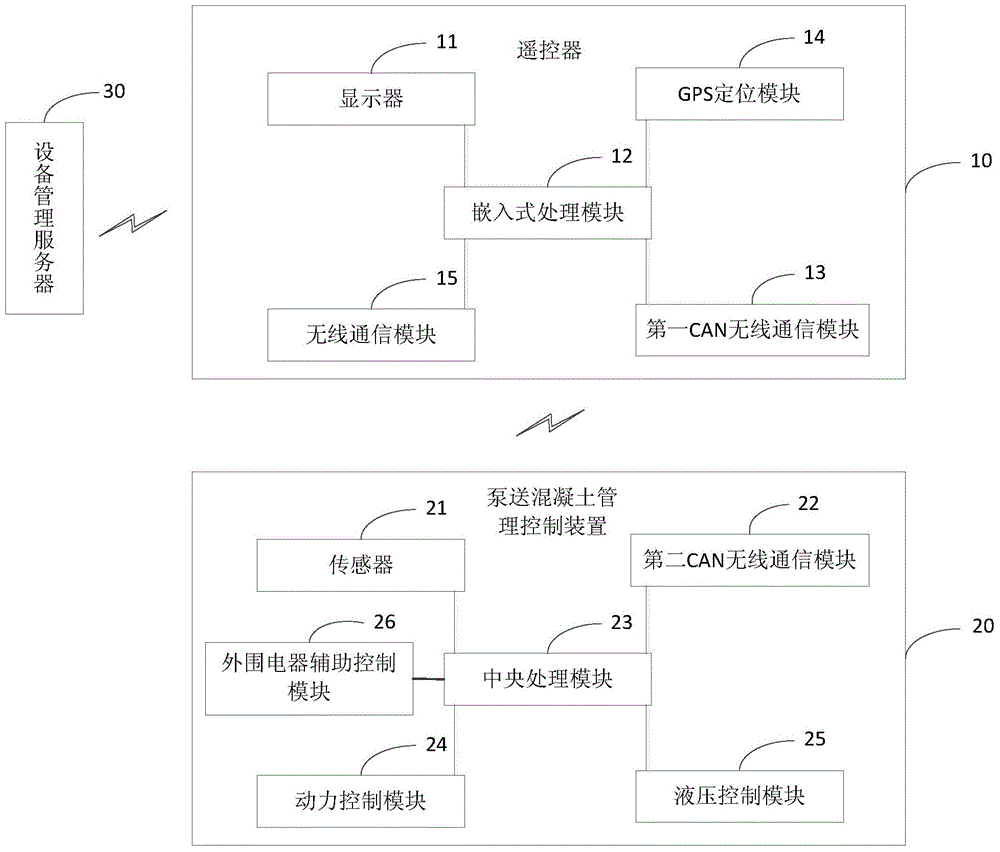

[0050] Step A, using a remote controller to send a control command to start the pumping concrete equipment to the equipment management server. In the prior art, the function of the remote control for controlling pumping concrete equipment is relatively simple and does not have multi-tasking processing capabilities, but the remote control used in the present invention is a remote control with multi-tasking processing functions. At the same time, as figure 2 As shown, the remote controller 10 is configured with a display 11, an embedded processing module 12, a first CAN wireless communication module 13 (using the Controller Area Network wireless communication technology), a wireless communication module 15 (using the GPRS mobile cellular data communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com