Multifunctional edible fungus mycelia production machine

A technology of mycelium and edible fungus, applied in the fields of application, horticulture, botanical equipment and methods, etc., can solve the problems of unfavorable high-quality production, medium infection of bacteria, etc., to overcome the susceptibility to infection of bacteria and reduce production costs , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

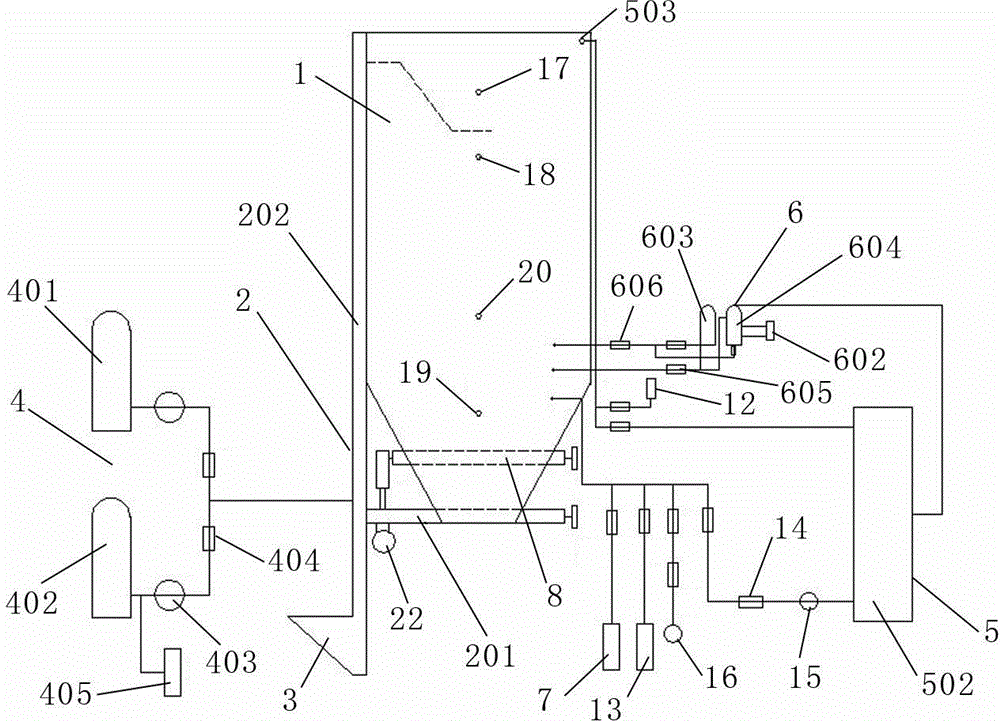

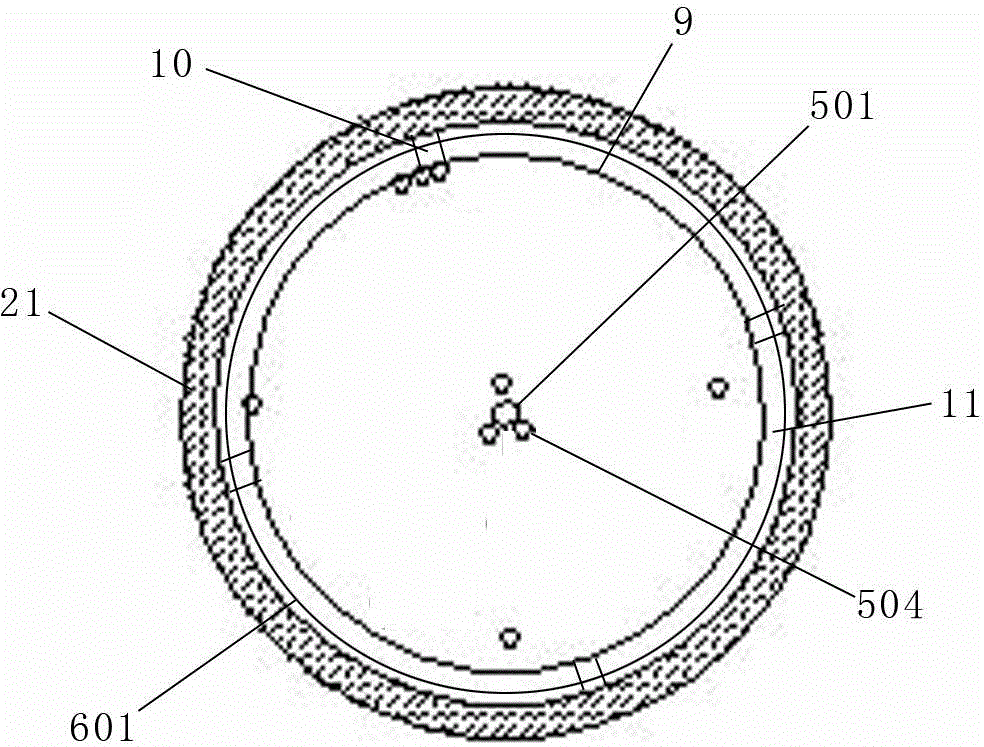

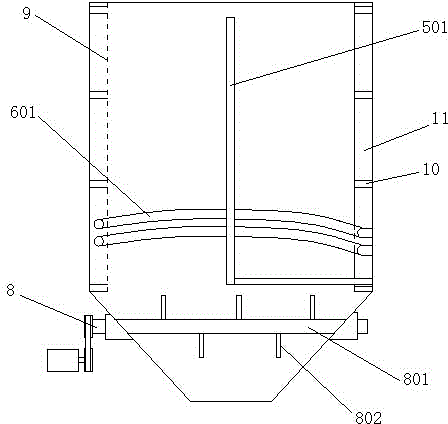

[0020] The specific structure and implementation mode of the present application will be described below in conjunction with the accompanying drawings

[0021] like figure 1 As shown, the multifunctional edible fungus mycelium production machine of the present application is provided with a main body 1 with a processing chamber inside. The upper part of the main body is provided with a material inlet, and the lower part is provided with a material outlet. The feed port and the discharge port are connected through the material circulation conveying mechanism 2, so that the materials output from the bottom of the processing bin can be sent into the processing bin from the feed port, so that the materials can be mixed in the process of circular conveying. figure 1 The material circulation conveying mechanism 2 shown includes a horizontal screw conveying device 201 connected to the lower discharge port of the main body 1 and a vertical feeding device 202 connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com