Wave-making oxygen increasing machine

An aerator and wave-making technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems that the wave amplitude cannot reach the expected value, the energy efficiency ratio has not been improved, and the wave amplitude is unbalanced. Balanced and uniform circumferential swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

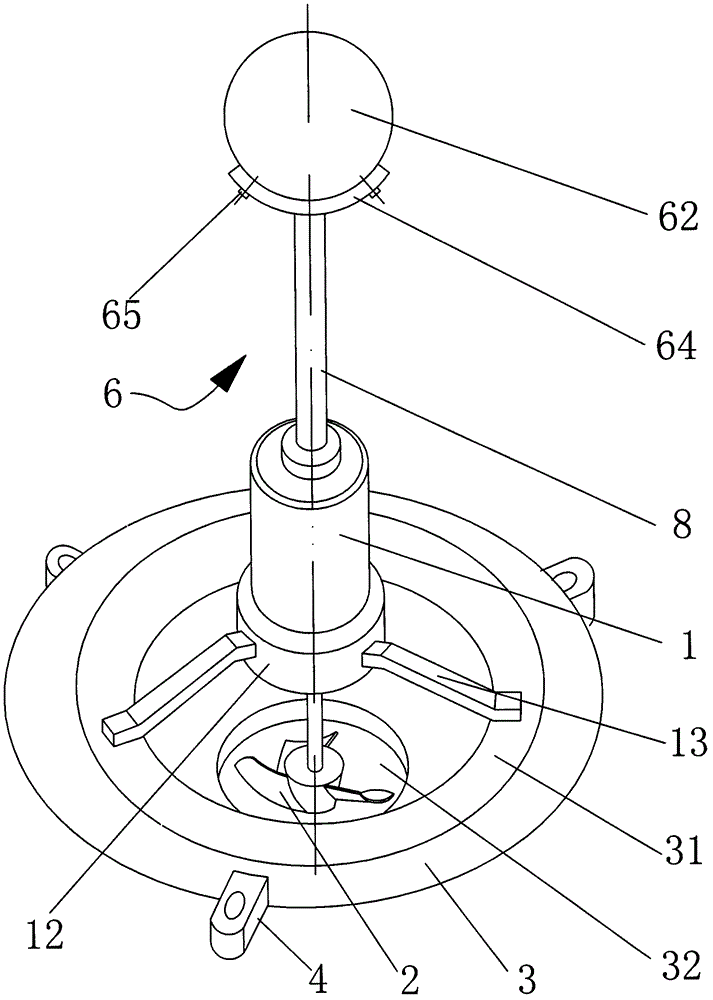

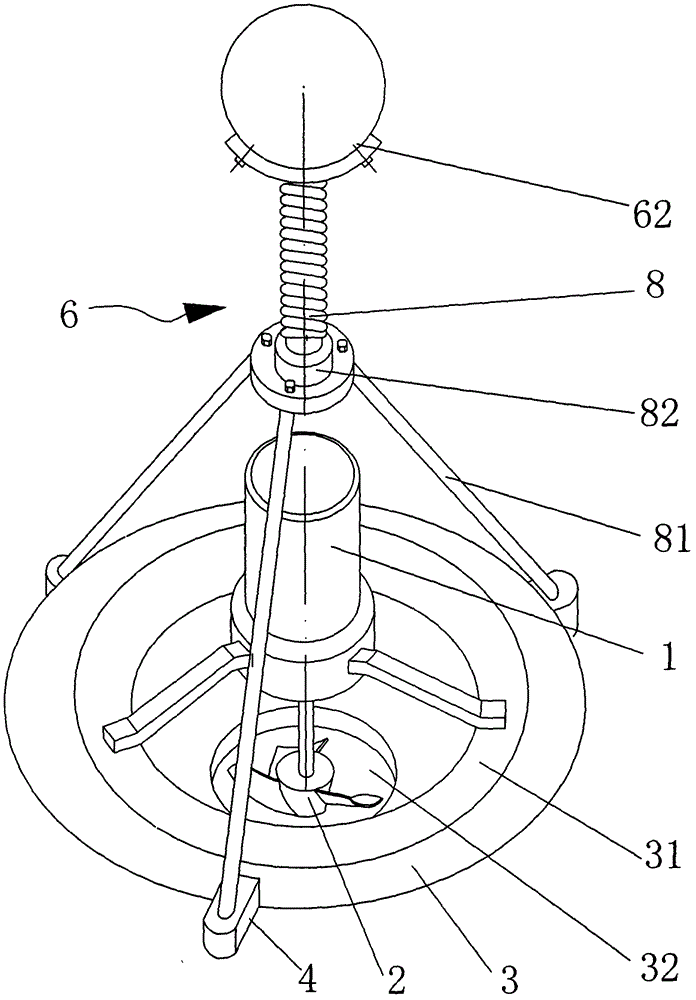

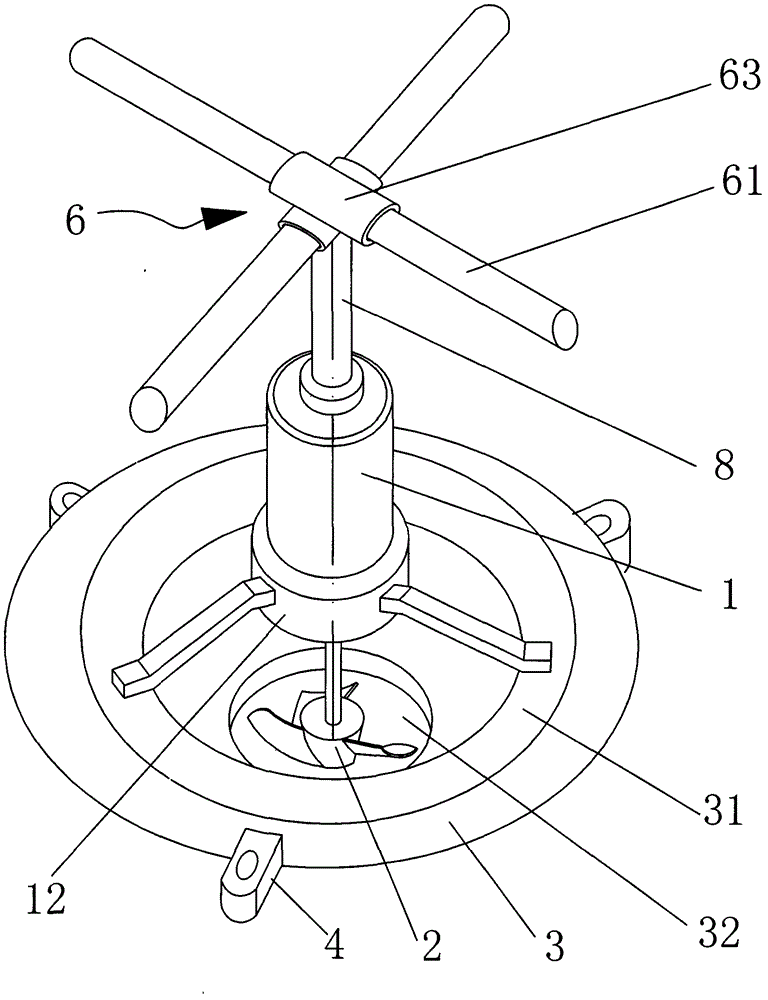

[0018] like figure 1 The first embodiment shown is a wave-making aerator, including a motor 1, a reducer 12, an impeller 2 and a floating body 3, the output shaft of the reducer is the impeller shaft, and the motor and the reducer are fixed on the floating body 3 through a bracket 13 , The positive triangle setting of the bracket can ensure the coaxial line between the motor and the floating body; the motor is a fully enclosed structure, and the motor drives the impeller 2 to rotate through the reducer during operation, and cools it by splashing water splashed from the churning up. The floating body 3 is in the shape of a ring, and its inner ring surface is made into an inverted cone surface 31. The impeller 2 is installed at the lower part of the opening 32 of the inverted cone surface. Spray to increase the dissolved oxygen in water. A swing driver 6 is installed on the top of the motor 1. The swing driver includes a pole and a counterweight ball 62 made of steel balls. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com