A kind of preparation method of soy sauce

A technology of soy sauce and crude oil, applied in food science and other fields, can solve the problems of poor water solubility and achieve stable color and red index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) 1 mass part of soybean meal was cooked at 125°C for 5 minutes, mixed with 1 mass portion of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.02% (w / w) of soybean meal weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the koji is obtained;

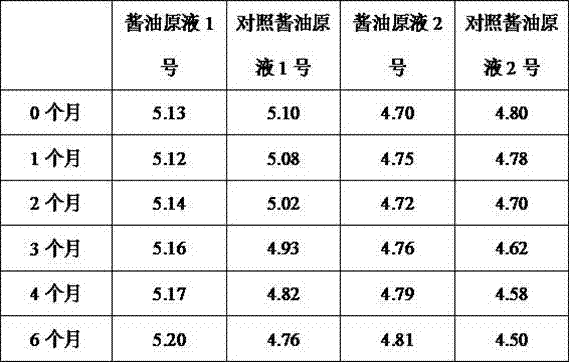

[0020] (3) Mix Daqu with 2.5 times the weight of 20% (g / g) brine, and ferment for 20 days using the high-salt dilute soy sauce brewing method (GB18186-2000) to obtain crude oil, add 0.01% (g / mL) of crude oil volume ) of transglutaminase, continued to ferment for 70 days, squeezed and filtered to obtain soy sauce stock solution No. 1.

[0021] The fermentation process of the control soy sauce sample is:

[0022] (1) 1 mass part of soybean meal was cooked at 125°C for 5 minutes, mixed with 1 mass portion of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.02% (w / w) of soybean meal weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the...

Embodiment 2

[0025] (1) 1 part by mass of soybeans was cooked at 125°C for 5 minutes, mixed with 0.5 part by mass of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.02% (w / w) of soybean meal weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the koji is obtained;

[0026] (2) Mix Daqu with 3 times the weight of 20% (g / g) brine, ferment for 30 days using the high-salt dilute soy sauce brewing method (GB18186-2000), add 0.1% (g / mL) of crude oil volume Glutaminase, continued to ferment for 60 days, squeezed and filtered to obtain No. 2 soy sauce stock solution.

[0027] The fermentation process of the control soy sauce sample is:

[0028] (1) 1 part by mass of soybeans was cooked at 125°C for 5 minutes, mixed with 0.5 part by mass of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.02% (w / w) of soybean meal weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the koji is obtained;

[0029] (2) Da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com