A control system for fully automatic orthopedic traction robot

A control system, fully automatic technology, applied in fractures, medical science, surgery, etc., can solve the problems of few safety protection measures, difficult to guarantee reliability, complex robot structure, etc., to improve accuracy, reduce labor intensity, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

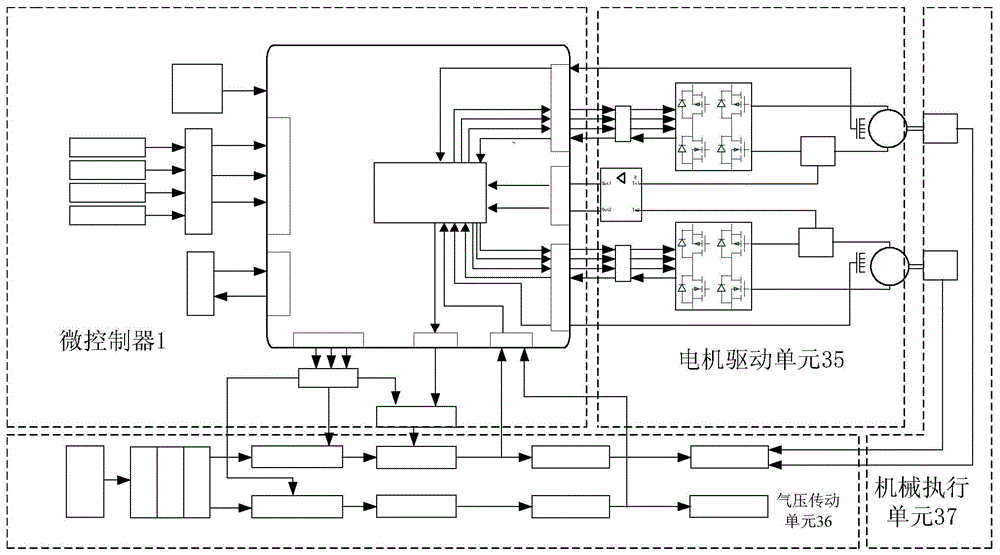

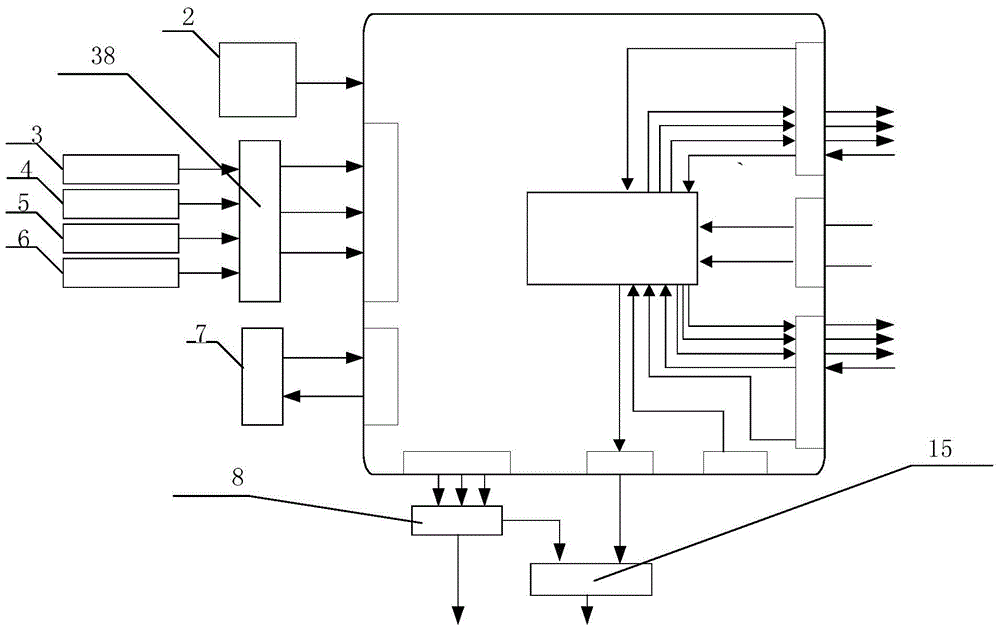

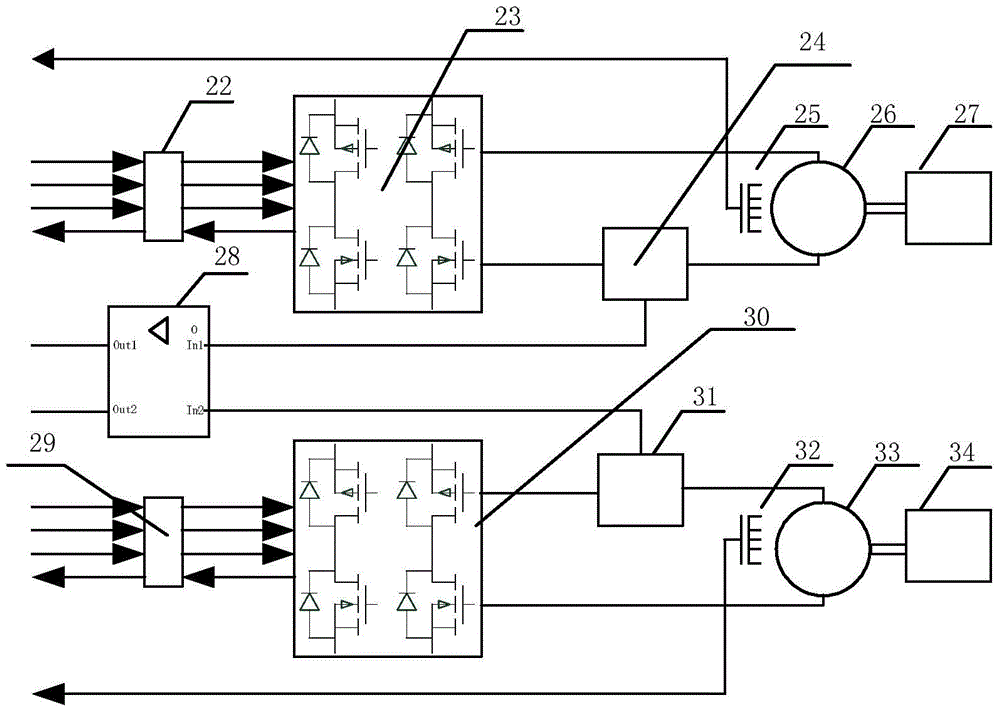

[0021] Such as figure 1 As shown, a control system for a fully automatic orthopedic traction robot provided by the present invention includes a microcontroller 1 and a clamping platform 20, and the microcontroller 1 is connected to a motor drive unit 35 and a pneumatic transmission unit 36 respectively. Communication connection, the motor drive unit 35 and the pneumatic transmission unit 36 are connected with the mechanical execution unit 37 of the automatic orthopedic traction robot, the pneumatic transmission unit 36 is connected with the clamping platform 20, and the motor The driving unit 35 is used to control the mechanical execution unit 37 to generate a deflection force, the pneumatic transmission unit 35 is used to control the clamping platform 20 to generate a stretching force and a clamping force, and the mechanical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap