Multistage filtering type waste gas purifying device

An exhaust gas purification device and stage filtration technology, which is applied in the field of air purification, can solve the problems of not achieving a good exhaust gas purification effect, polluting the atmospheric environment, and increasing the cost of the enterprise, so as to improve the access efficiency, thoroughly purify the exhaust gas, and realize recycling. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

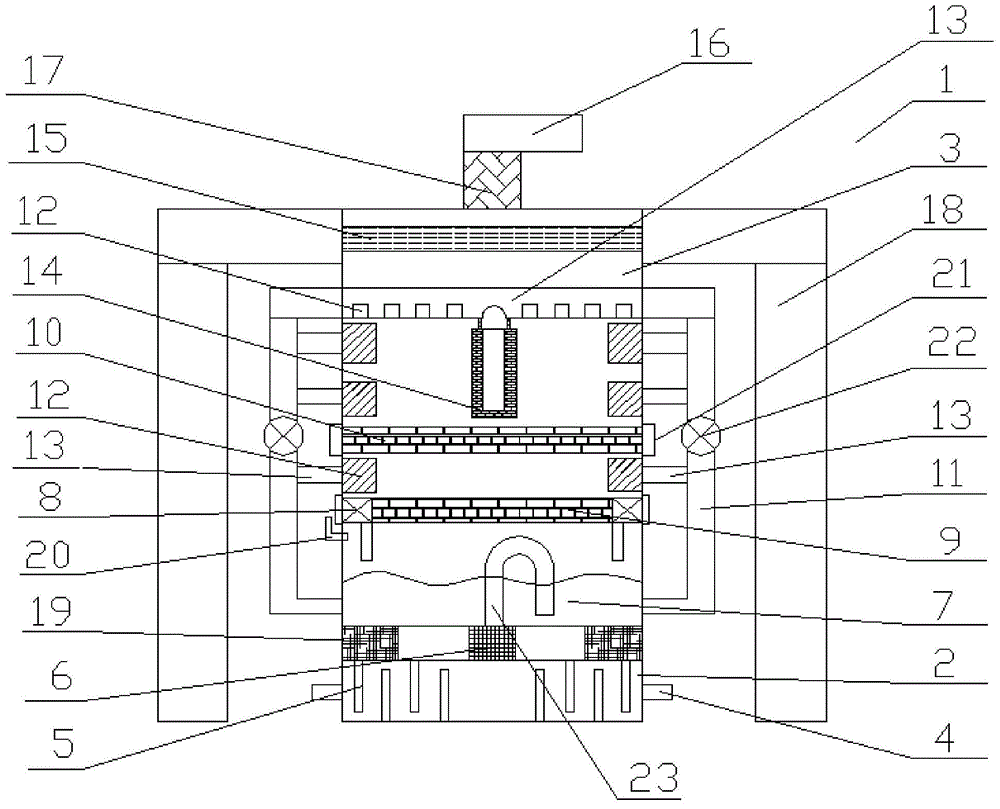

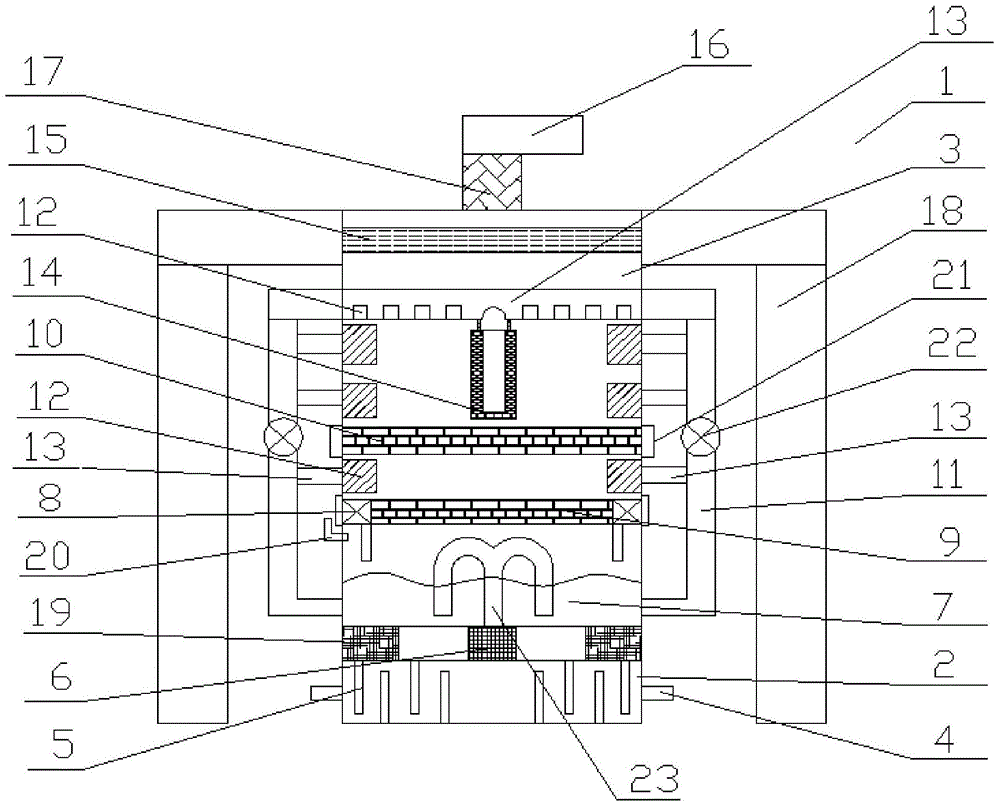

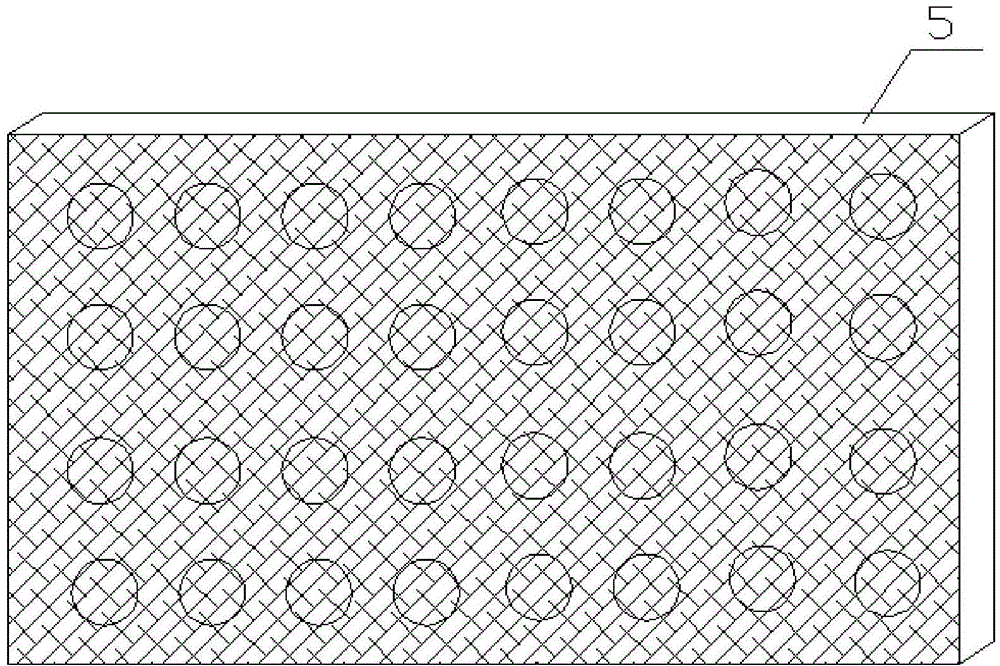

[0035] Such as figure 1 , image 3As shown, the first specific embodiment of the present invention is: a multi-stage filter type exhaust gas purification device, including a body 1, the body 1 includes a sedimentation chamber 2, a purification chamber 3, an air inlet 4 and an air outlet 16, The settling chamber 2 is arranged below the body 1, the air inlet 4 is symmetrically arranged at both ends of the settling chamber 2, and the inside of the settling chamber 2 is provided with a plurality of evenly arranged dust shields 5, the dust shields The plate 5 is made of stainless steel and arranged vertically. A plurality of through holes are provided on the dust shield 5, and the outer surface of the dust shield 5 is also covered with a layer of primary filter. At the bottom of the clean room 3 A liquid storage tank 7 is provided, and one side of the liquid storage tank 7 is provided with a liquid filling port 20, and the surrounding wall of the body where the liquid storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com