Multi-head drilling machine

A drilling rig and multi-head technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems that the processing accuracy cannot be well guaranteed and the work efficiency is low, so as to ensure the position and guarantee constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Such as Figure 9 As shown, the workpiece has four mounting holes 100 that need to be drilled.

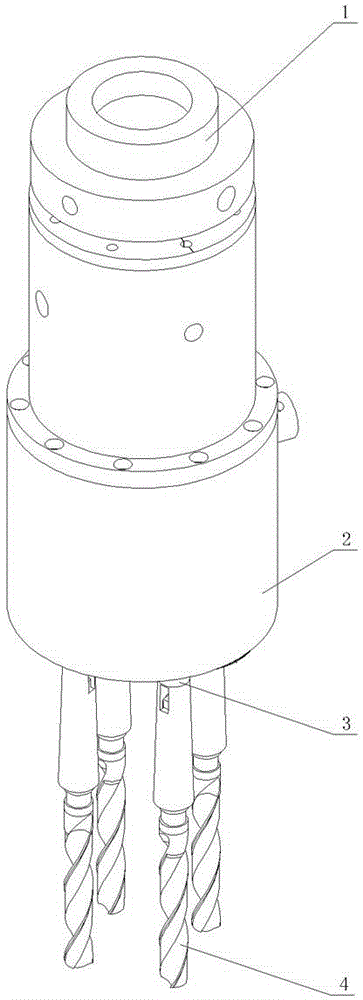

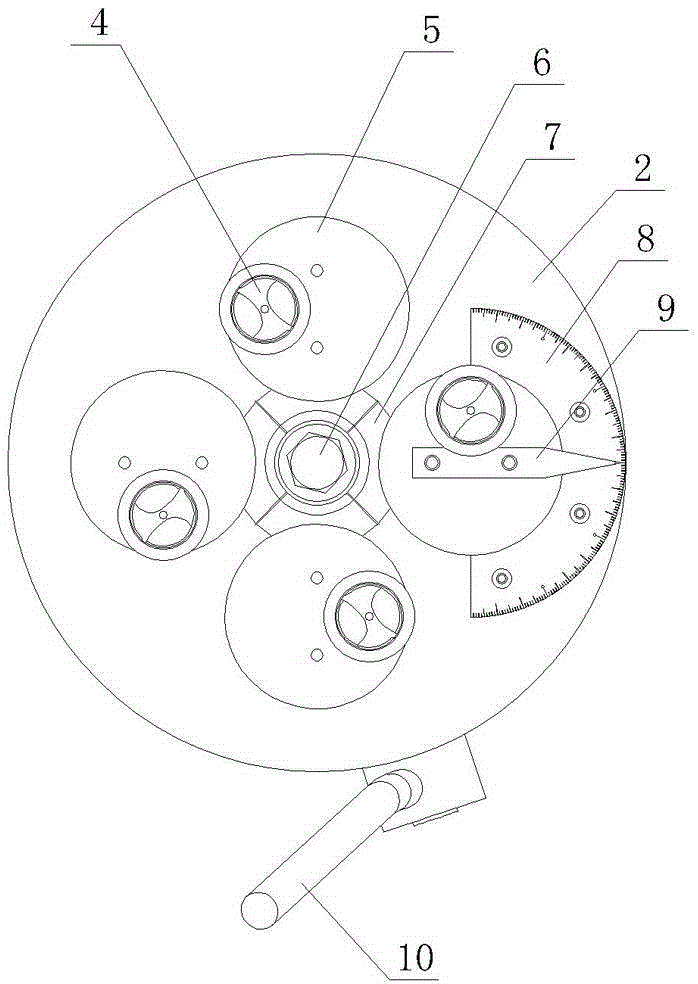

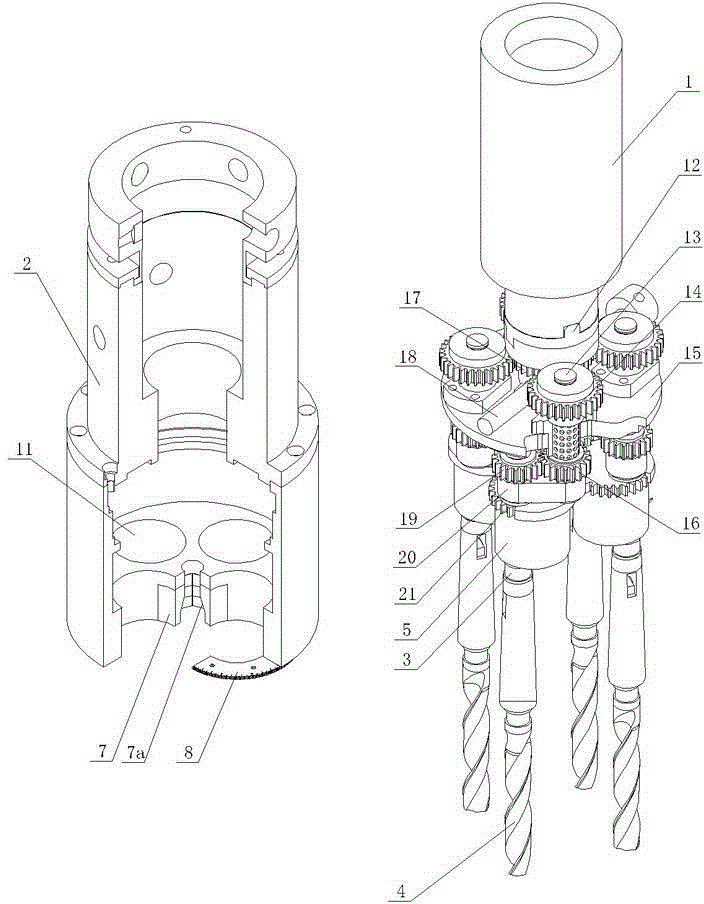

[0021] Such as Figure 1-8 As shown, the multi-head drilling rig of the present invention includes a housing 2, a turntable 15 coaxially arranged in the housing 2, a main power gear 17 and a main adjustment gear 22, and the main power gear 17 is connected to the motor 1 through the clutch tooth structure 12 connection, the motor 1 is fixedly installed on the top of the housing 2, four auxiliary power gears 14 meshing with the main power gear are evenly distributed around the main power gear 17, and the four auxiliary power gears 14 are connected to four power transmission shafts 13, four The power transmission shaft 13 is rotated on the turntable 15, and the turntable 15 is rotated in the housing 2. The power transmission shaft 13 is also connected with the first gear 16, and the main adjustment gear 22 is connected with the adjustment rod 6. The main adjustment gear 22 Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com