Welding Process of Aluminum Alloy Roof for Subway Cars

A welding process and aluminum alloy technology, which is applied in the field of aluminum alloys, can solve the problems of affecting assembly, affecting product qualification rate, and high comprehensive cost, and achieve the effects of reducing welding man-hours, optimizing welding process parameters, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

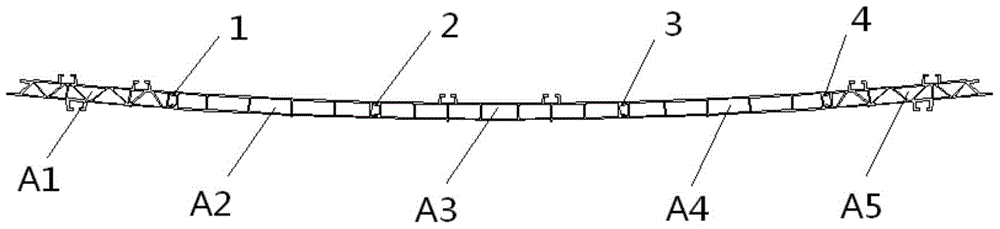

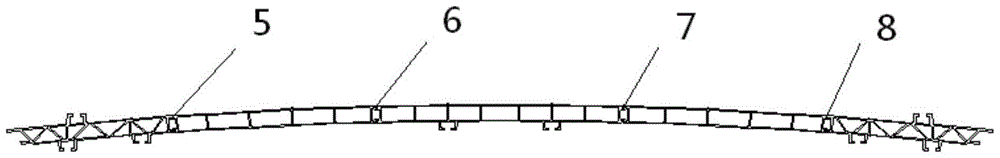

[0033] Such as Figure 1-5 As shown, the car body roof of the subway in this embodiment is welded by five roof panels A1, A2, A3, A4, and A5 and two roof side beams B1 and B2.

[0034] In this embodiment, the roof of the car body is welded in two stages. First, each roof panel is welded, and then the roof side beam and the roof panel assembly are welded, as follows:

[0035] (1) Roof plate welding:

[0036] 1), material selection: select the above-mentioned roof panel as required, and the roof panel is a hollow profile with a single length of 16-20m, a width of 0.3-0.6mm, and a wall thickness of 2-3mm;

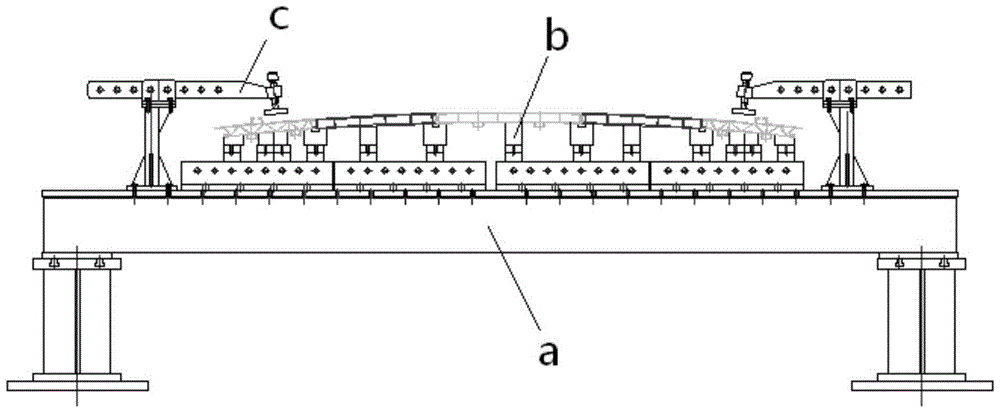

[0037] 2) Formal assembly: set the selected five roof panels side by side on the formal welding tool;

[0038] 3) Form-fitting welding: double-machine and double-wire linkage welding is used to weld the roof panels of the formal-fitting assembly. First, welding seams 2 and 3 are welded at the same time, and then welds 1 and 4 are welded at the same time;

[0039] 4) Reverse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com