Laser flight cutting method and system

A cutting method and technology of a cutting system, which are applied in the field of laser applications, can solve problems such as low processing efficiency, poor cutting quality, and non-straight cutting square holes, and achieve the effects of saving costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

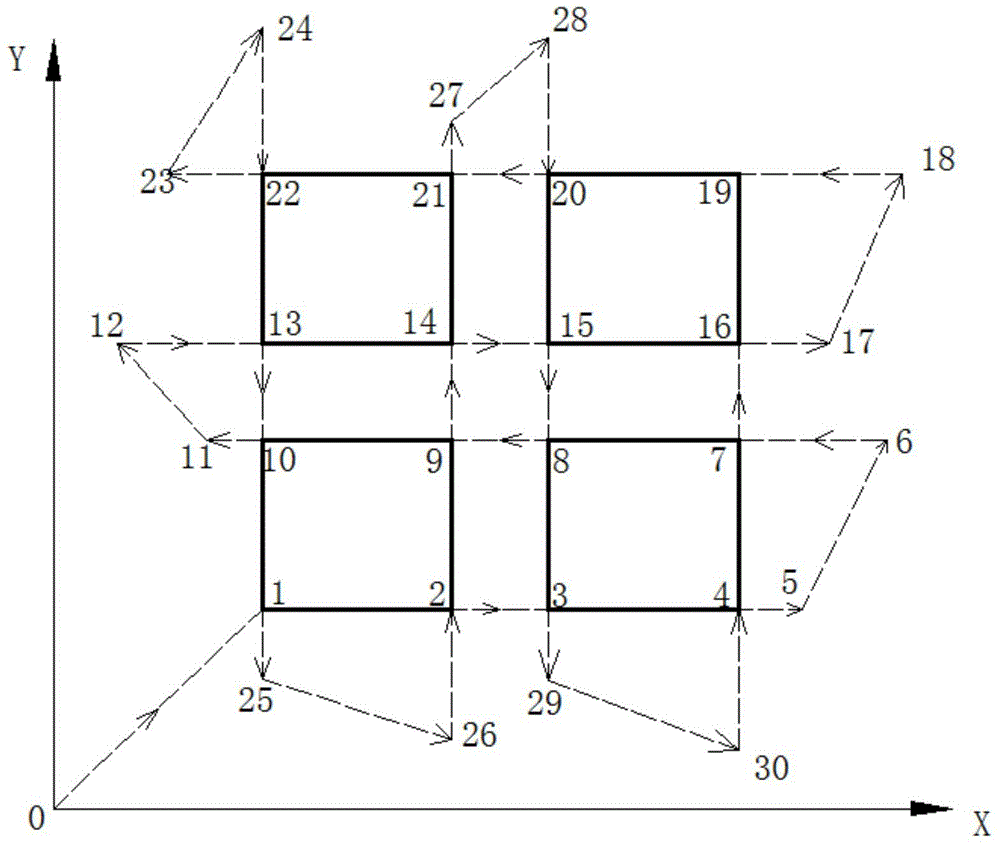

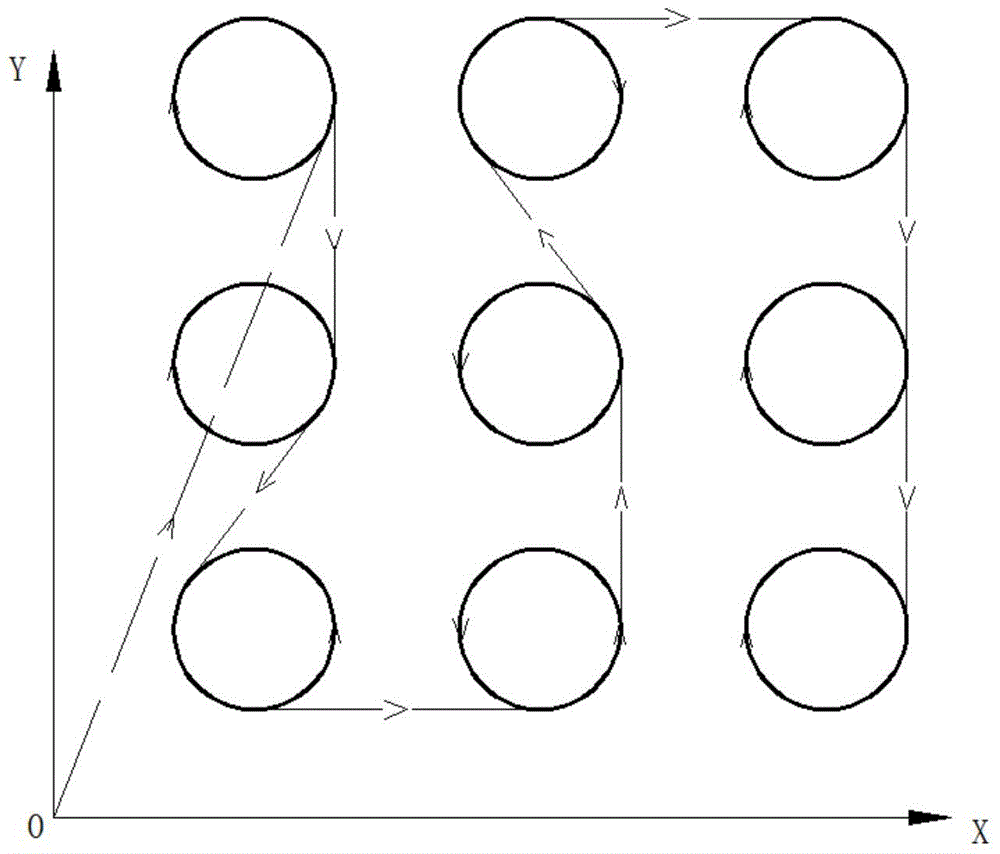

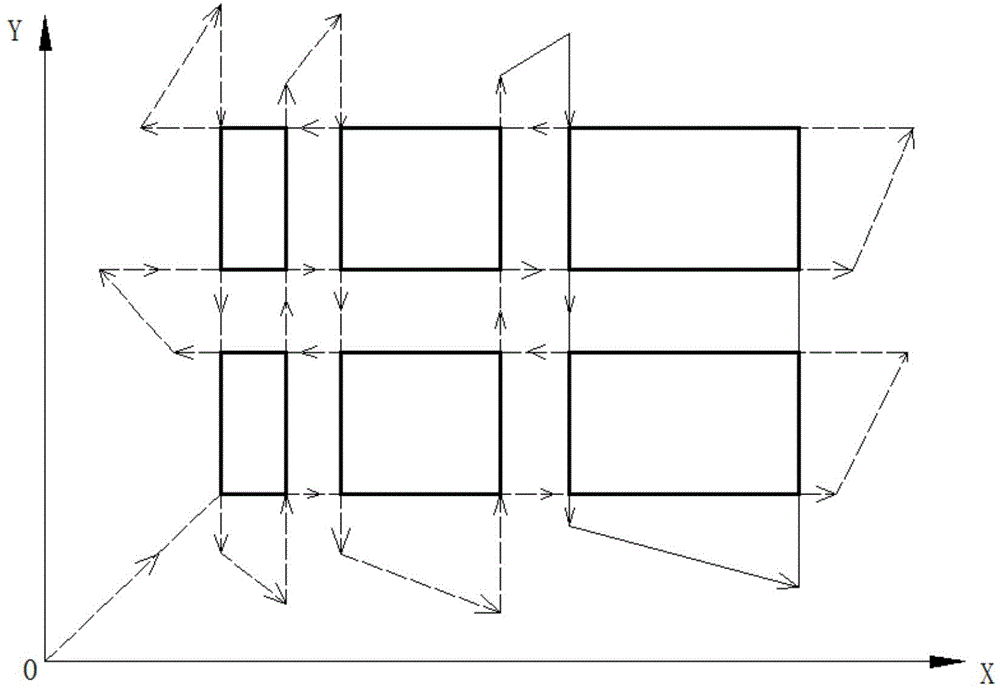

[0025] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0026] An embodiment of the present invention provides a laser cutting method on the fly, which includes the following steps: first generate a flight cutting trajectory, the trajectory includes several cutting paths, wherein the processing contour characteristics on the same cutting path are the same; then control the laser cutting head along the The flying cutting track runs quickly from the starting point of the cutting path to the end point of the cutting path, turns around at the end point of the cutting path, enters the starting point of the next cutting path and quickly runs to the end point of the cutting path until all the cutting is completed. At the same time, when the laser cutting head runs to the starting point of any processing contour on the cutting path, the laser turns on, and when it reaches the end point of the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com