Vending machine lift and anti-theft pickup structure

A technology of vending machines and lifts, which is applied in the field of improvement of vending machines’ anti-theft and cargo-retrieving structures, can solve the problems of poor control accuracy, large frictional resistance, inconvenient installation and maintenance, etc., and achieves reducing labor intensity, improving production efficiency, convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

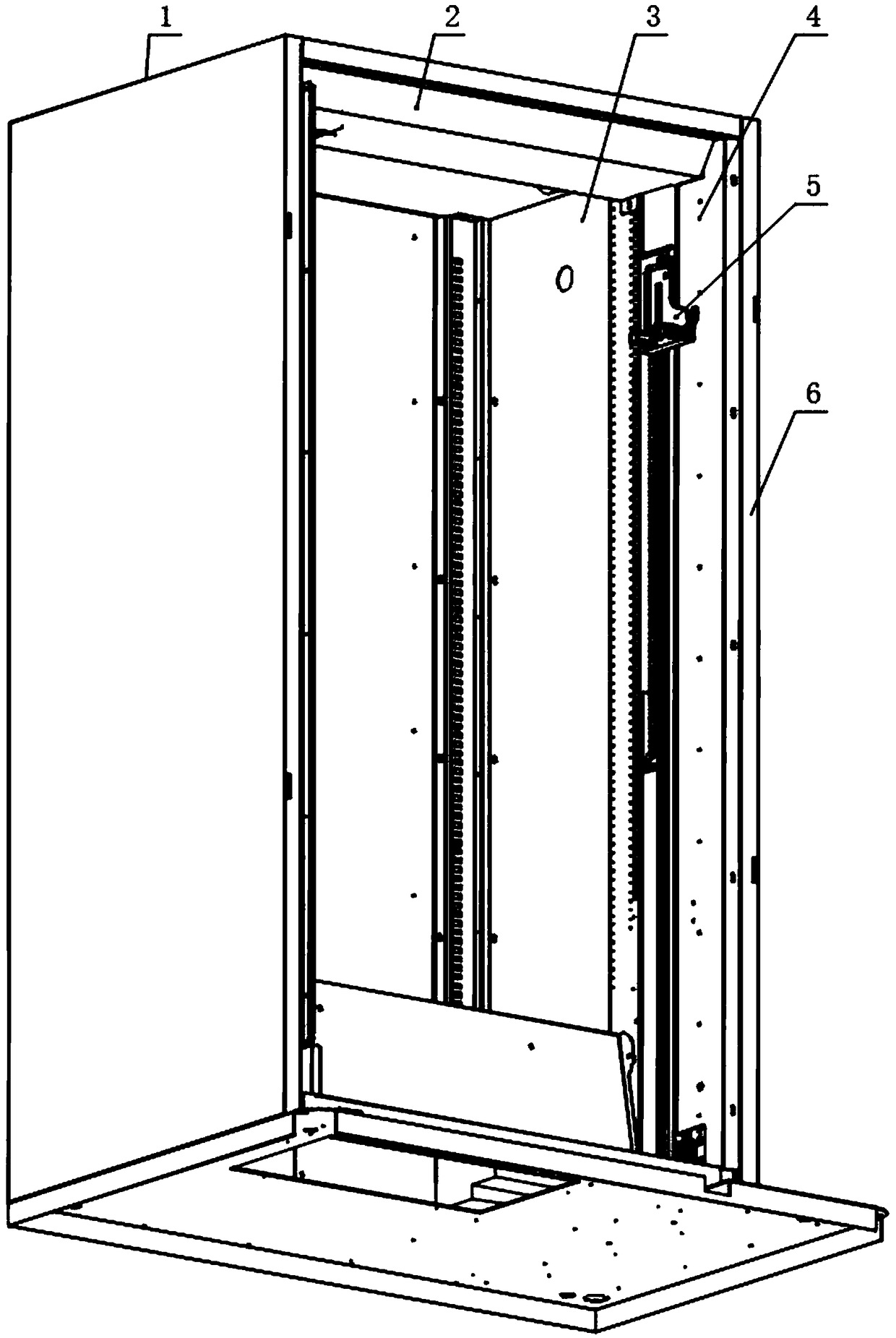

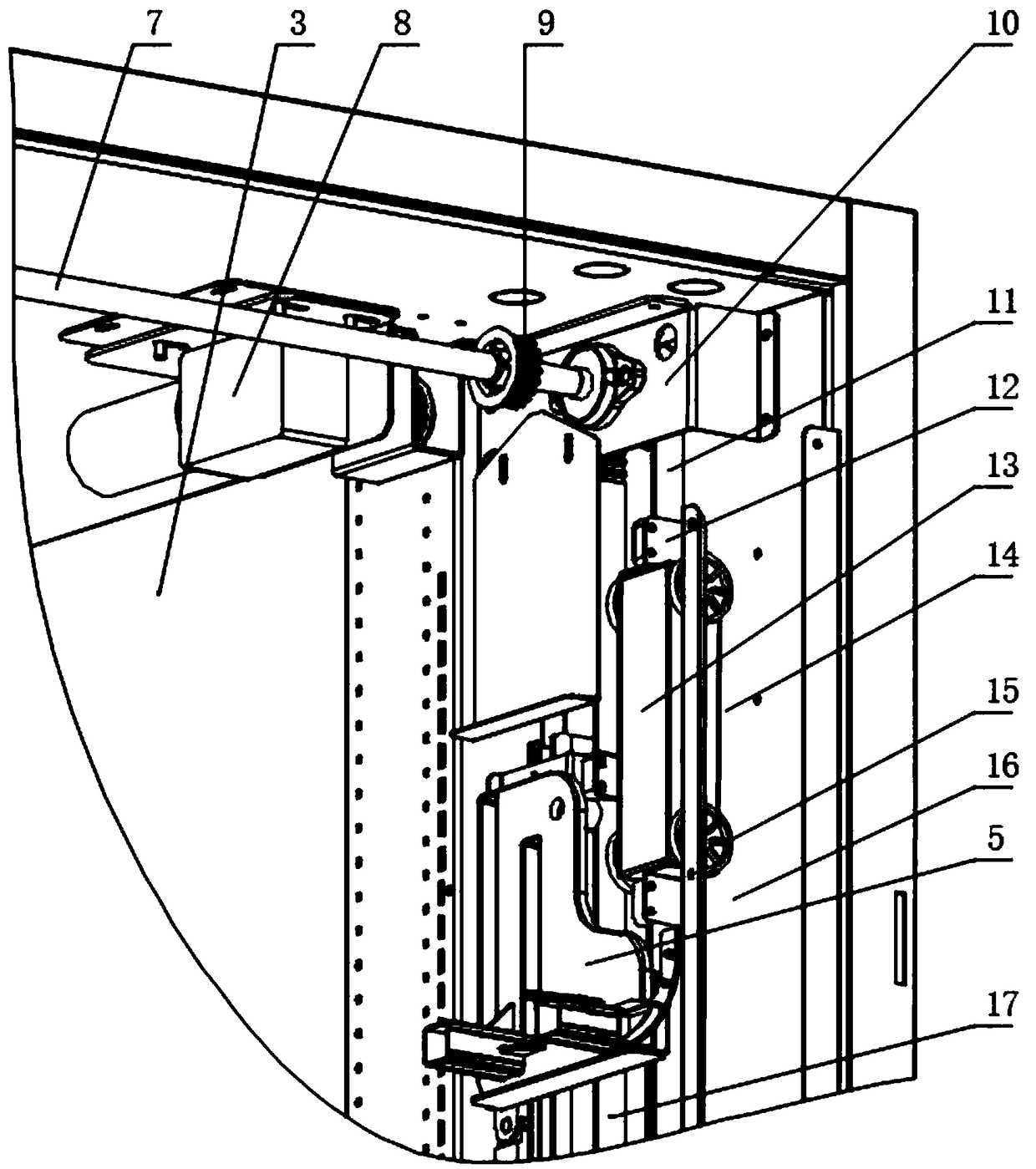

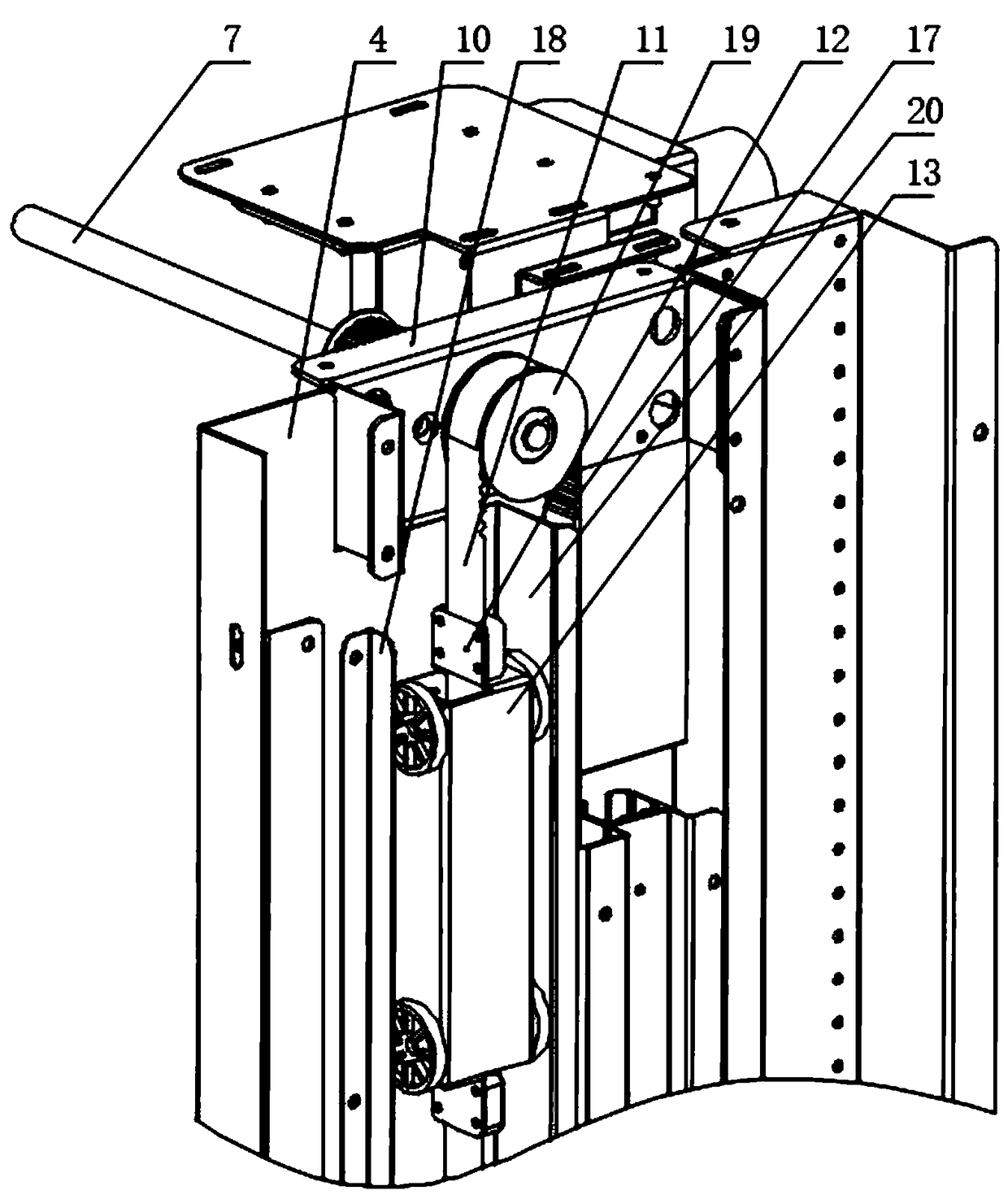

[0052] A vending machine elevator installation structure, such as Figure 7 , 8 , 9, and 10, the elevator 5 includes a bottom plate 24 and a side plate 22, and a side plate is installed at both ends of the bottom plate, and the lifting action is completed by a belt 17, and the belt is arranged on the side walls 3 on both sides of the vending machine box 1 near the box. At the opening 6 of the body, the innovation of the present invention lies in that a follower plate 21 is provided on the two belts through the fixing piece 12, and the inner side of each follower plate is limited to clamp a side plate on the same side.

[0053] In this embodiment, a bent edge 43 is provided at the lower end of the inner surface of the follower plate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com