Master-slave gantry lathe bed structure with double Z axes

A bed and gantry technology, applied in the field of master-slave double Z-axis gantry bed structure, can solve the problems of reducing the processing auxiliary time of clamping and alignment, and achieve shortened processing preparation time, high processing efficiency, and processing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

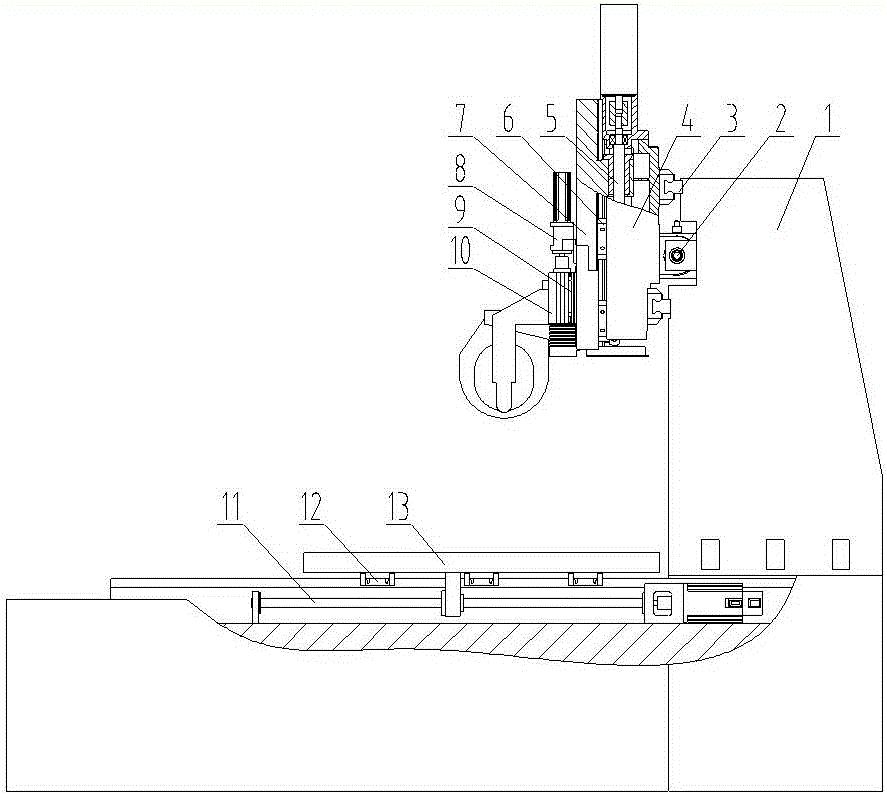

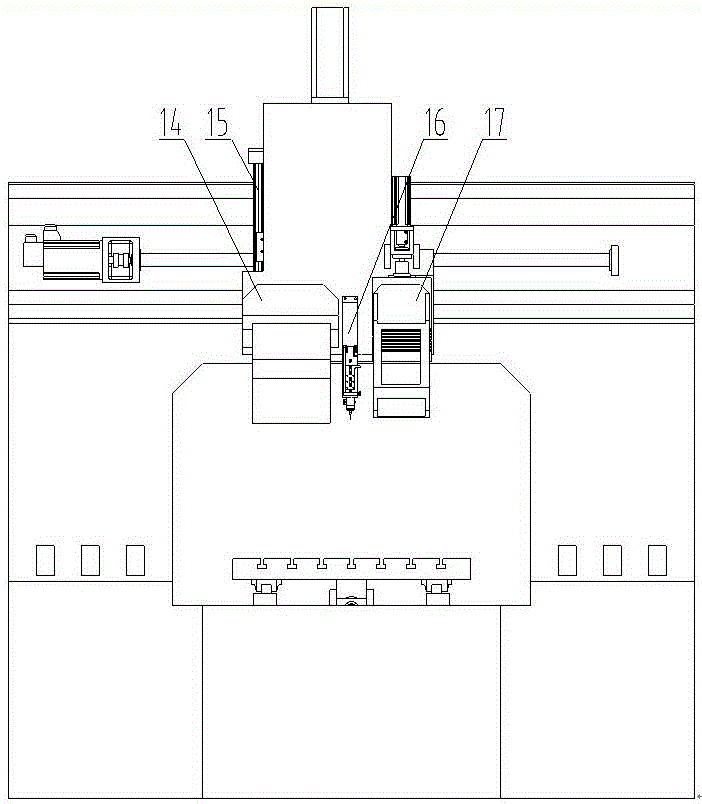

[0010] In the figure, the present invention relates to a master-slave double Z-axis gantry bed structure, including a gantry bed 1, a Y-axis drive system 2, a Y-axis guide system 3, a Y-axis slide 4, and Z 1 Shaft drive system 5, Z 1 Shaft guidance system 6, Z 1 Axle slide 7, Z 2 Shaft drive system 8, Z 2 Shaft Guidance System 9, Z 2 Axis slide 10, X axis drive system 11, X axis guide system 12, X axis slide 13, Z 1 Shaft actuator 14, Z 1 And Z 2 Shaft counterweight hydraulic cylinder 15, probe 16, Z 2 Axis actuator 17.

[0011] The X-axis drive system 11, X-axis guide system 12, and X-axis slide 13 are installed on the base of the gantry bed 1, and the X-axis drive system 11 drives the X-axis slide 13 to move within the X-axis stroke; Y-axis drive system 2. The Y-axis guide system 3 and Y-axis slide 4 are installed on the column of the gantry bed 1, and the Y-axis slide 4 is driven by the Y-axis drive system 2 to move within the Y-axis stroke; 1 Shaft drive system 5, Z 1 Shaft Gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com