Miniature 3D printing system on table

A 3D printing, small-scale technology, applied in the field of object rapid prototyping system, can solve problems such as waste, and achieve the effect of rapid prototyping and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

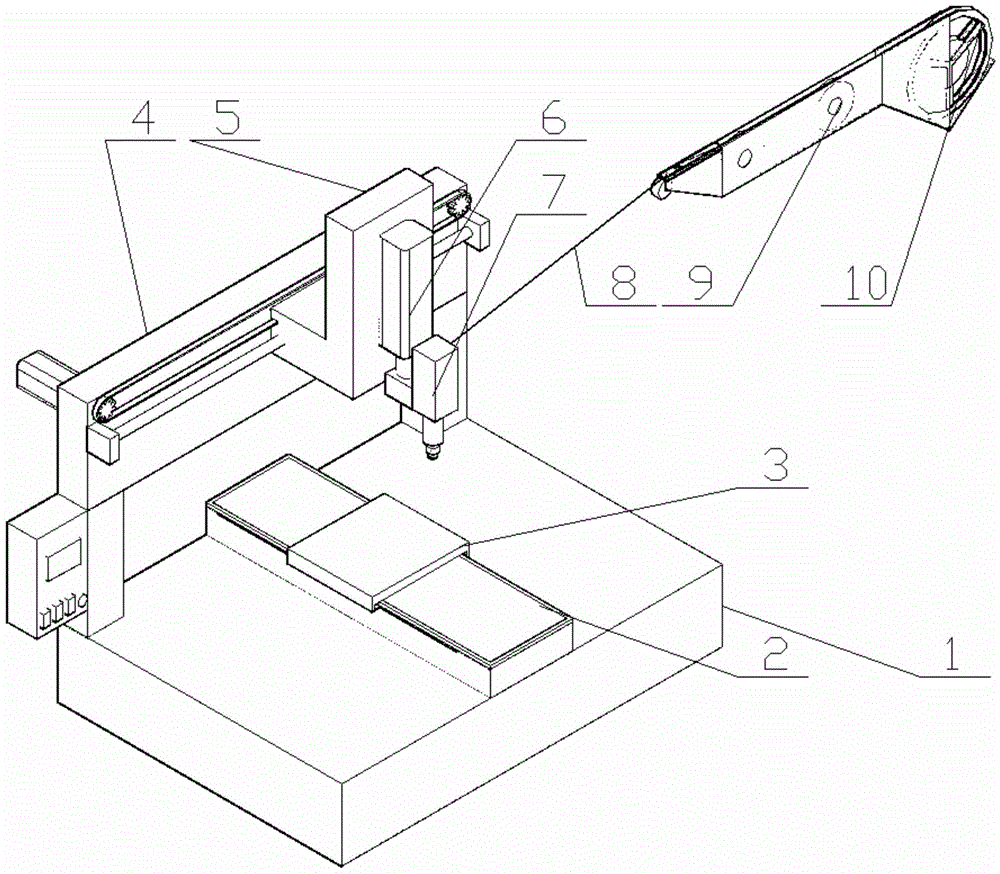

[0013] The accompanying drawing shows a specific embodiment of the present invention, a small desktop 3D printing system of the present invention, including a base 1, a housing 2 is fixedly installed on the base 1, and a vertically moving plate 3 is installed in the housing 2 due to driving The vertical driving device that moves along the length direction of the housing 2, the bracket 4 is also fixedly installed on the base 1, the horizontal driving device for driving the horizontal moving block 5 to move along the horizontal moving direction is installed on the bracket 4, and the electric motor is fixedly installed on the horizontal moving block 5 Strut 6, print head 7 is fixedly installed on the output shaft of electric strut 6;

[0014] It also includes a feeding device for feeding the strip-shaped molding material 8 into the print head 7 , the feeding device includes a feeding tray 10 , and the strip-shaped molding material 8 on the feeding tray 10 is fed into the print hea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap