Treatment method for wastewater containing organic matters during production of N-phenyl maleimide

A technology of maleimide and production process, applied in the field of treatment of wastewater containing organic matter, can solve problems such as environmental pollution, impact on human health, human survival crisis, etc., and achieve the effects of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

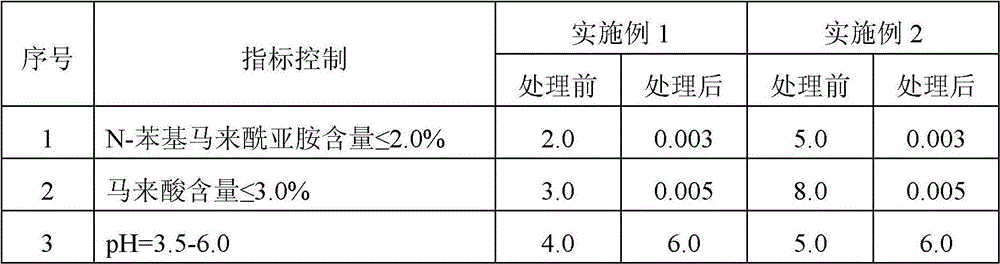

Embodiment 1

[0018] The waste water (wherein N-phenylmaleimide content is 2wt%, and maleic acid content is 3wt%, pH=4) containing organic matter in 1000g N-phenylmaleimide production process is at 20 ℃, Pass through the treatment column that 2000g 732 cation exchange resins are housed with the speed of 10ml / min under the condition of 0.15MPa, then pass through the treatment post that 2000g macroporous weakly basic resin is housed with the same pressure condition and speed, will obtain to remove organic matter Wastewater is discharged into the anaerobic pond for routine treatment. The test results of wastewater show that the wastewater COD before treatment Cr The value is greater than 50000mg / L (theoretical value), the chemical oxygen demand COD of the organic matter in the treated wastewater cr 95mg / L, biochemical oxygen consumption BOD 5 It is 25mg / L.

Embodiment 2

[0020] The waste water (wherein N-phenylmaleimide content is 5wt%, and maleic acid content is 8wt%, pH=5) containing organic matter in 1000g 5% N-phenylmaleimide production process is at 40 Under the conditions of ℃ and 0.15MPa, pass through the treatment column equipped with 5000g 732 cationic resin at a rate of 10ml / min, and then pass through the treatment column equipped with 5000g macroporous weakly basic resin under the same pressure conditions and speed, and the organic matter will be removed. The waste water is discharged into the anaerobic pond for routine treatment. The test results of wastewater show that the wastewater COD before treatment Cr The value is greater than 140000mg / L (theoretical value), the chemical oxygen demand COD of the organic matter in the treated wastewater Cr 95mg / L, biochemical oxygen consumption BOD 5 It is 25mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap