CNC system for 3D printing, generation method of printed documents and printing method

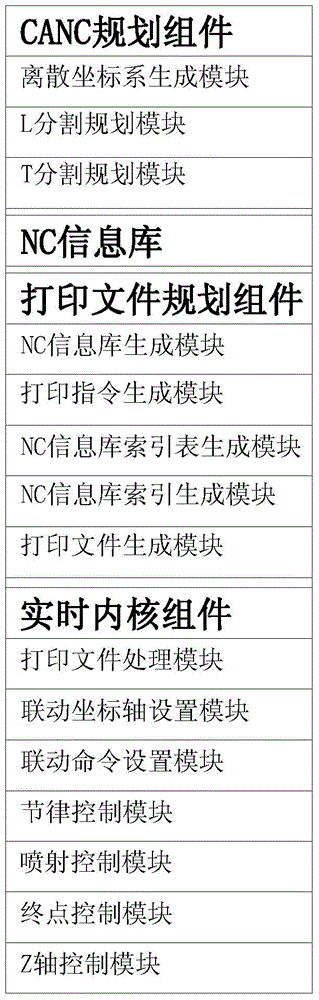

A technology of 3D printing and printing files, applied in the field of 3D printing, can solve the problems of reducing printing speed and printing quality, poor readability of G code programs, difficult to use and exchange and sharing, etc., to achieve simple time control, save storage space, The effect of increased printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0226] As we all know, 3D printing can be divided into two types of forming technologies, selective deposition and selective connection. Selective deposition The molten printing material is selectively deposited, and the solid ratio is formed. Selective connection lays down the printing material first, and then selectively sprays the adhesive for bonding and molding; or laser selective scanning for solid ratio molding.

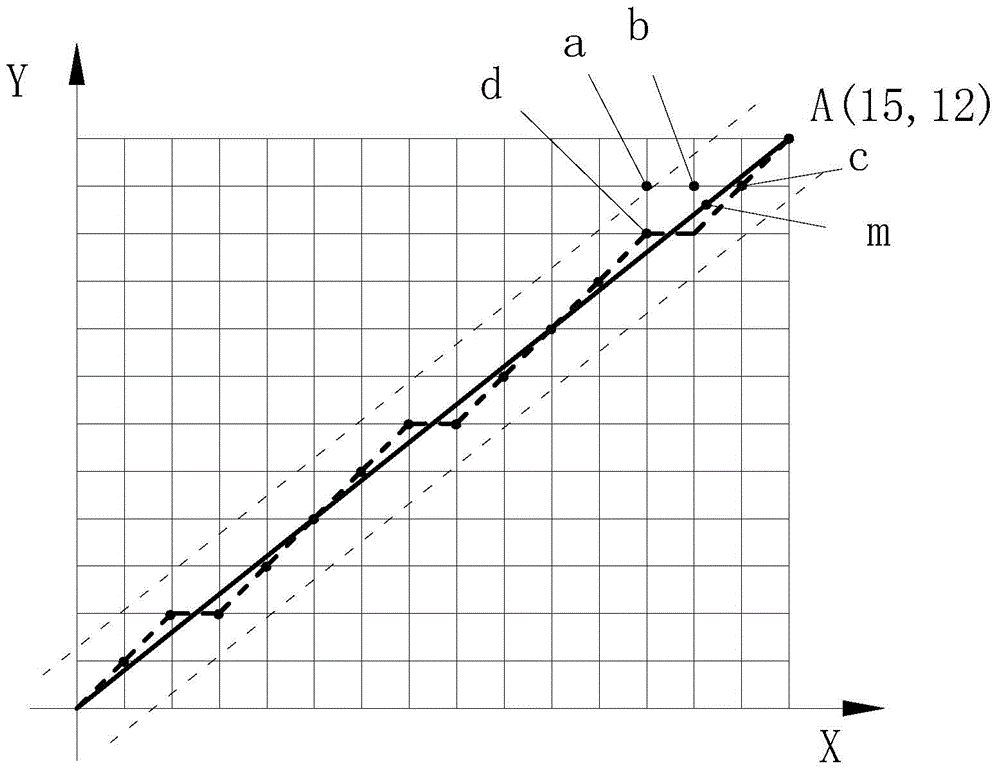

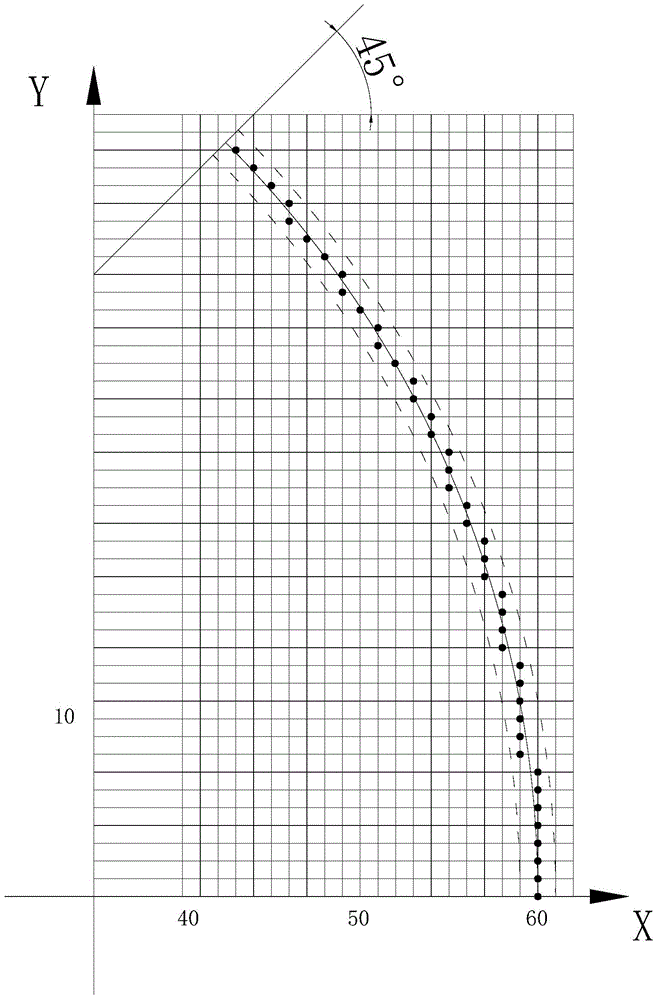

[0227] Generally speaking, no matter what kind of molding technology is used, the basic principle of a 3D printer is a liftable workbench for laying printing materials. One or more nozzles for ejecting (plastic / metal / adhesive) droplets, (plastic / ceramic / metal) powders; or for emitting laser beams. The nozzle moves in a curve relative to the worktable under the control of the X-axis / Y-axis, and the Z-axis controls the lifting of the worktable.

[0228] Any complex three-dimensional solid can be decomposed into a series of thickness δz i The superposition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com