Snow removing briquetting car

A vehicle and snow collection technology, which is used in snow removal briquetting vehicles, conveying, continuous snow removal, briquetting and side push-out combined operation equipment, and collection fields, which can solve the problems of environmental pollution, high cost, and limited use scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

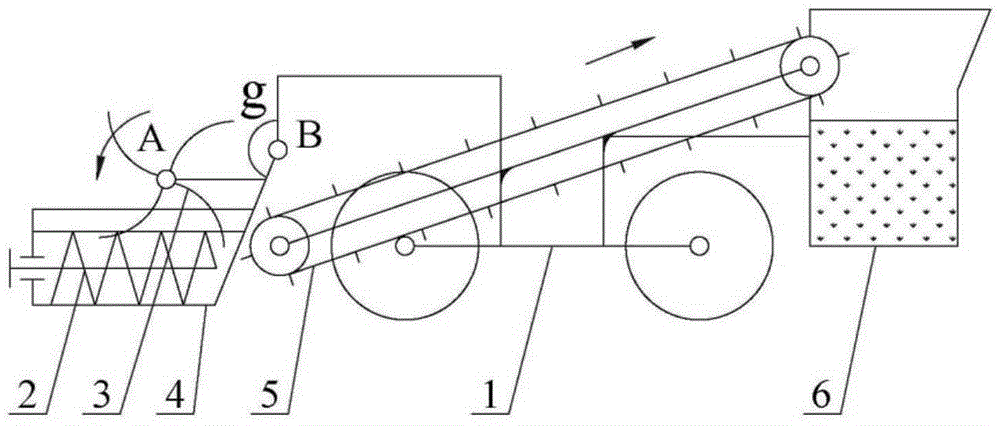

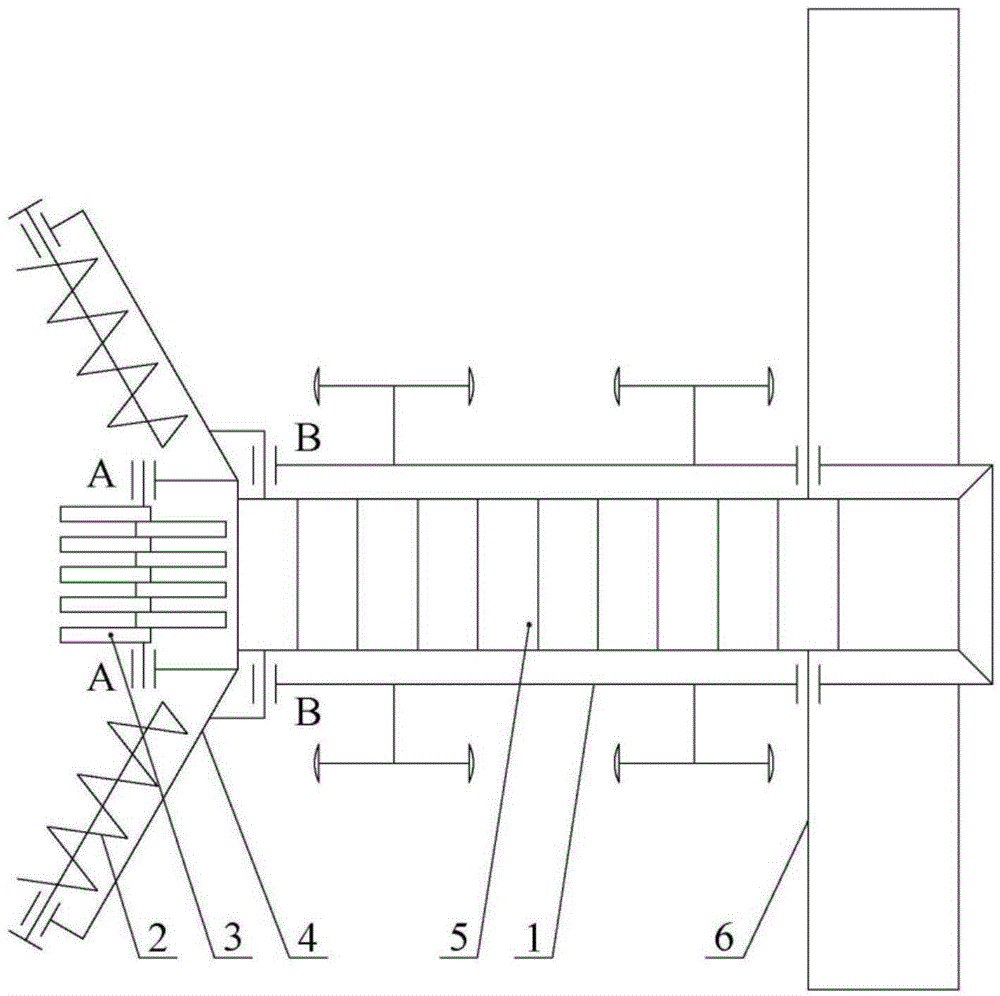

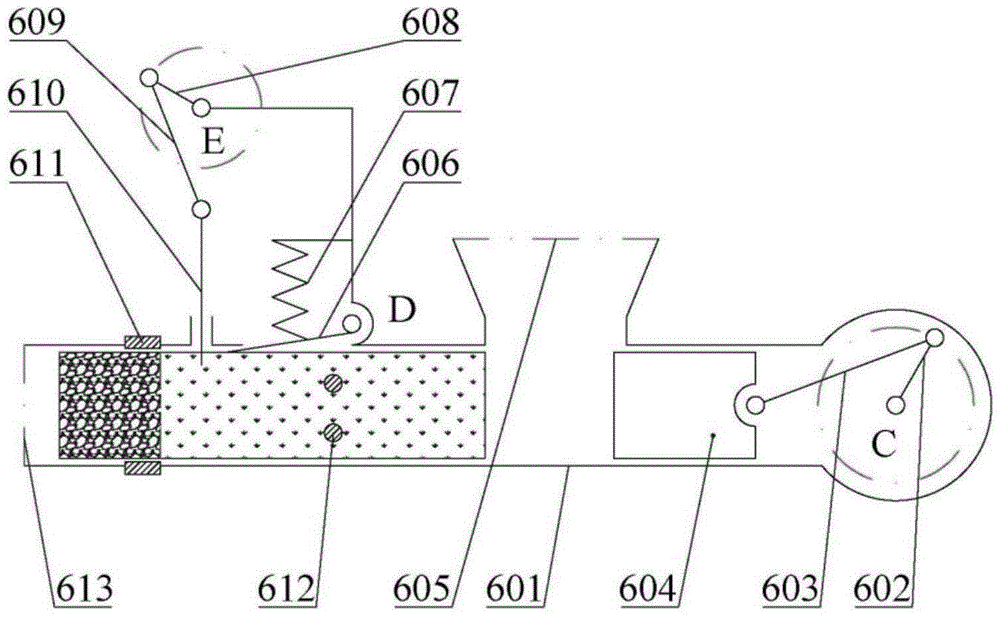

[0023] figure 1 The schematic diagram of the front view of the snow removal and briquetting vehicle is shown. The snow removal and briquetting vehicle includes: chassis 1, snow collecting screw 2, snow shifting wheel 3, V-shaped snow shovel 4, conveyor belt 5, and briquetting device 6. It is self-propelled, The upper front end of the wheeled chassis 1 is symmetrically provided with a V-shaped snow shovel 4, the middle part is provided with a longitudinal conveyor belt 5, and the horizontally placed briquetting device 6 is fixedly connected to the frame at the rear end of the chassis 1 through its body 601. The vehicle frame of snow shovel 4 and chassis 1 rotates and connects at point B in the vertical vertical plane of the vehicle, and the axis of rotation BB (such as figure 2 As shown), the attitude of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com