Internal wall paint with air purification function and preparation method thereof

A technology for interior wall coatings and air purification, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., to achieve the effects of high fullness of the paint film, strong adhesion, and good scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

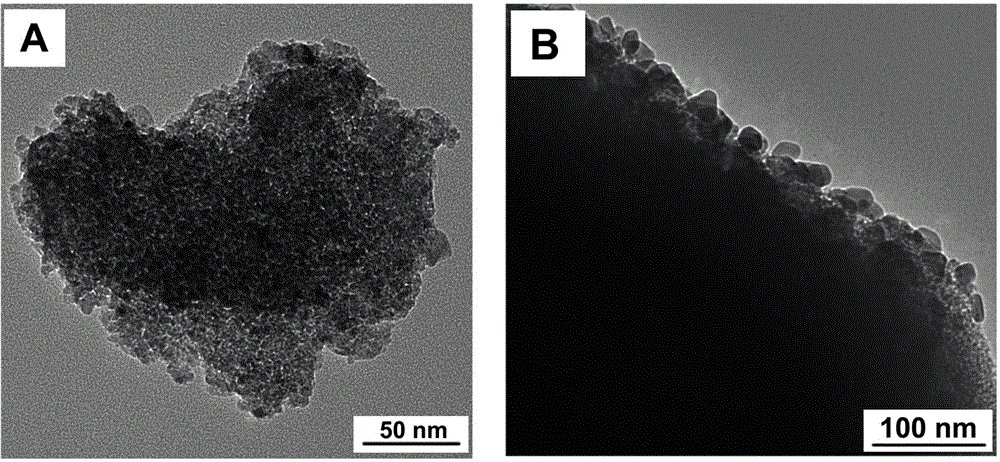

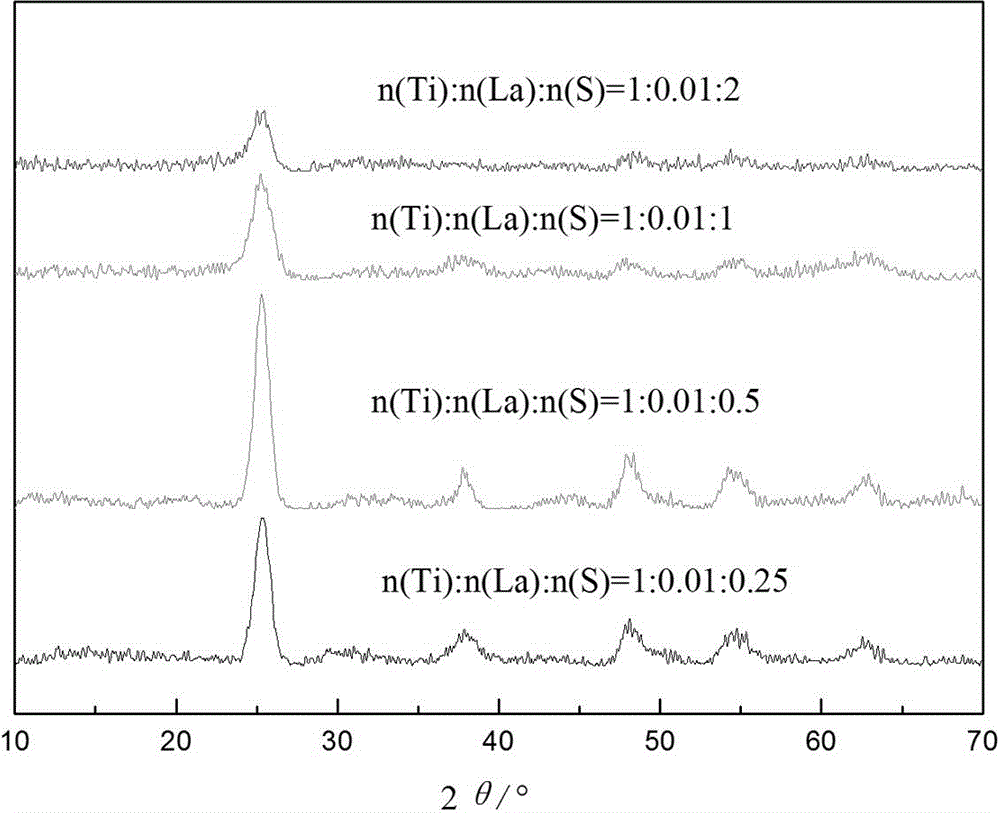

Image

Examples

preparation example Construction

[0037] A kind of preparation method of interior wall coating with air purification function, its preparation steps are:

[0038] Step 1: Take the dispersant, thickener, antifreeze, leveling agent, dodecyl alcohol and 70% of the formula amount of water according to the ratio of parts by weight and add them to the container, stir and mix them thoroughly for 20 minutes to obtain mixture;

[0039] Step 2: To the mixed solution prepared in step 1, add acidity regulator with formula quantity of 10%, defoamer with formula quantity of 20%, preservative, antifungal agent and 2-amino-2-methyl-1- Propanol, and stir and mix for 10min;

[0040] Step 3: Add pigments and 25% of the formula water to the mixed solution prepared in step 2 in sequence, stir and mix thoroughly, then add 30% of the formula defoamer to it, and continue to stir and mix for 30 minutes, after that, use The disperser fully disperses the mixed material to make a slurry;

[0041] Step 4: Add water-based fluorocarbon r...

Embodiment 1

[0059] Step 1: Take 3.50 kg of sodium polyacrylate, 1.50 kg of carboxymethyl cellulose, 1.50 kg of 1,2-propylene glycol, 1.00 kg of polyether-modified polysiloxane, 3.50 kg of dodecyl alcohol and 12.6 kg of water Add it into the reaction kettle, stir and mix thoroughly for 20 minutes to obtain a mixed solution;

[0060] Step 2: Add 0.1kg of sodium hydroxide, 0.14kg of tributyl phosphate, 0.15kg of 1,2-benzisothiazolin-3-one, and benzimidazole carbamic acid to the mixed solution prepared in step 1. Methyl ester 0.15kg and 2-amino-2-methyl-1-propanol 2.0kg, and stirred and mixed for 10min;

[0061] Step 3: Add 18kg of pigment and 4.5kg of water to the mixed solution prepared in step 2 in turn, stir and mix thoroughly, then add 0.21kg of tributyl phosphate to it, and continue to stir and mix for 30min, after that, use a disperser Fully disperse the mixed material to make a slurry;

[0062] Step 4: Add 44.0 kg of water-based fluorocarbon resin emulsion, 0.35 kg of tributyl phosp...

Embodiment 2

[0072] Step 1: Take 4.0 kg of sodium oleate, 2.0 kg of hydroxyethyl cellulose, 2.0 kg of ethylene glycol, 2.00 kg of polyether-modified polysiloxane, 4.0 kg of lauryl ester alcohol and 9.1 kg of water into the In the reaction kettle, after fully stirring and mixing for 20 minutes, a mixed solution was obtained;

[0073] Step 2: Add 0.15 kg of potassium hydroxide, 0.2 kg of polydimethylsiloxane, and 1,3,5-tris(2-hydroxyethyl)-s-triazine to the mixed solution prepared in step 1 0.25kg, 0.25kg of 3-iodo-2 propargyl butyl carbamate and 3.0kg of 2-amino-2-methyl-1-propanol, and stir and mix for 10min;

[0074] Step 3: Add 10kg of pigment and 3.25kg of water to the mixed solution prepared in Step 2 in turn, stir and mix thoroughly, then add 0.3kg of polydimethylsiloxane to it, and continue to stir and mix for 30min, after that, Use a disperser to fully disperse the mixed material to obtain a slurry;

[0075] Step 4: Add 50 kg of water-based fluorocarbon resin emulsion, 0.5 kg of p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap