Yarn bracing and sizing all-in-one machine

An all-in-one machine and yarn technology, applied in textiles and papermaking, fiber processing, textile material processing and other directions, can solve the problems of burning materials that do not meet the environmental protection requirements of clean energy, repetitive processes, and high energy consumption, and achieves reduction of repetitive processes. The effect of reducing production cost and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further explanation in conjunction with accompanying drawing.

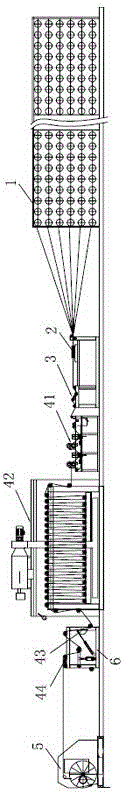

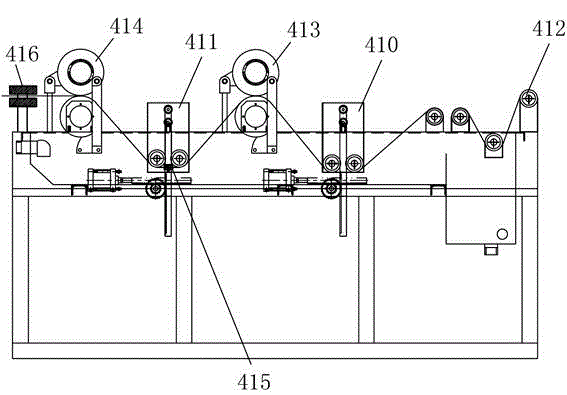

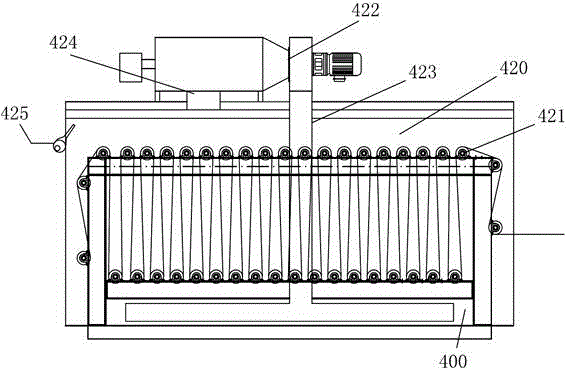

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: a yarn drawing and sizing integrated machine, including a creel 1, a yarn dividing reed 2, a tensioner 3, a sizing and drying device and a yarn winding head 5 arranged in sequence. Creel 1 can be set with 600-1000 embryo yarns. Yarn dividing reed 2 divides each embryonic yarn on the creel 1 into a row of yarns, and the separated rows of yarns are transmitted to the sizing and drying device through the tensioner 3 under the pull of the yarn winding head 5 through each yarn guide roller Inside.

[0025] The sizing and drying device is provided with a sizing unit 41 and an air drying unit 42, and between the sizing and drying device and the yarn winding head 5 is also provided with a burning hair processing unit 43 and a waxing unit 44, and the sizing unit 41 and the air drying unit 42 , a burner processing unit 43 and a waxing unit 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com