Pile foundation bearing characteristic model test device and method under complicated load effect

A model test device and function technology, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems that the test results cannot accurately reflect the actual situation, the loading direction is single, and the pile body is not set, so as to avoid artificial Estimated reading error, easy to operate, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

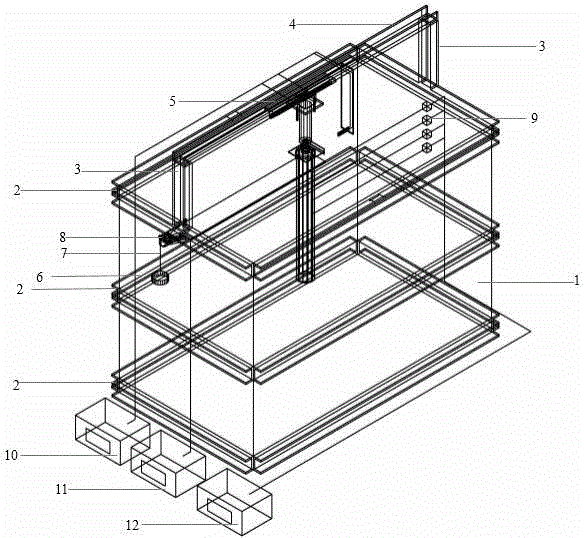

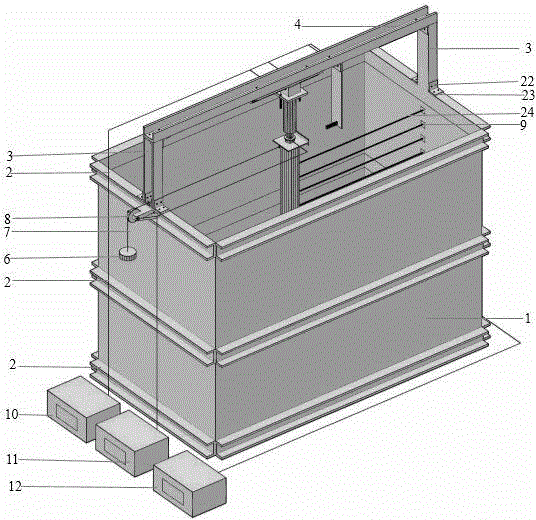

[0046] The pile foundation bearing characteristic model test device under the complex load action of this embodiment is as follows figure 1 and 2 As shown, it includes a model tank, a horizontal loading system, a vertical loading system, and a loading device.

[0047] Wherein the model groove is made by organic glass plate 1, and adopts channel steel 2 to reinforce. The horizontal loading system is composed of pulley 8, weight plate and weight 6, and steel wire rope 7.

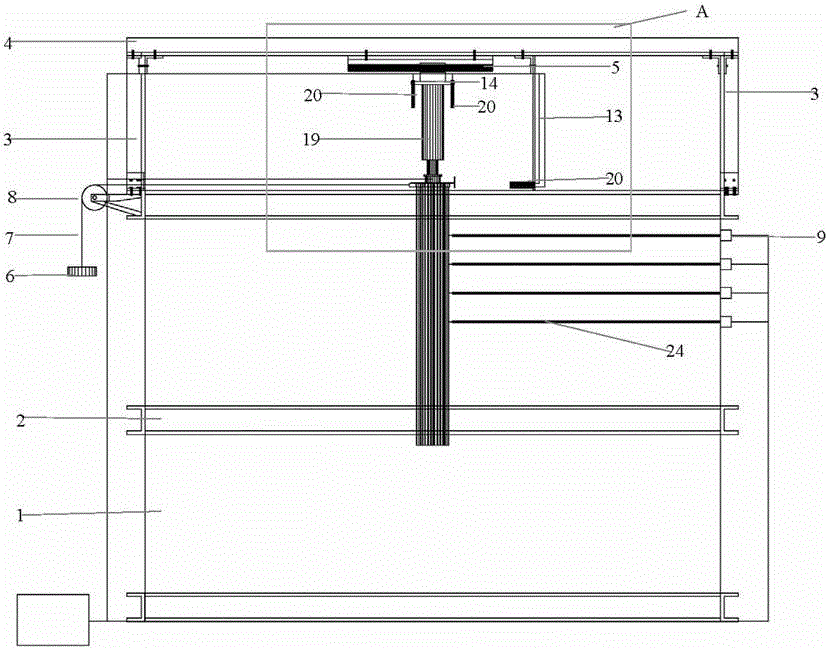

[0048] Vertical loading systems such as image 3 and Figure 4 As shown, it is composed of a vertical channel steel 3, a reaction beam 4, a jack 19, and a linear sliding guide rail 5. The linear sliding guide rail 5 is fixed to the reaction beam by screws 22, and is fixed with the placement steel plate 14 and the jack 19 as a whole by the screws 22. , the jack 19 applies a vertical load, and can move horizontally along the linear sliding guide rail 5, which can maintain the stability of the vertical lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com