A protective treatment method for karst caves at the top of tunnels

A technology of karst caves and tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as vegetation reduction, restriction of project progress, instability, etc., and achieve the effects of simple production process, good governance effect, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

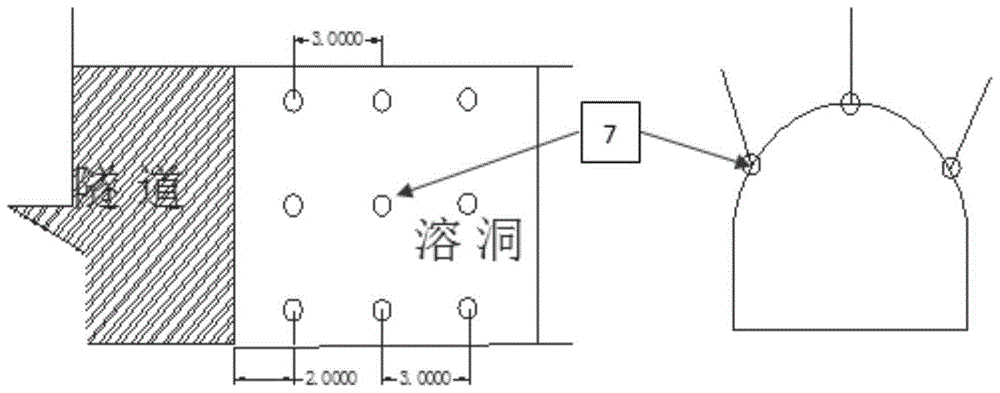

[0030] A protective treatment method for a karst cave at the top of a tunnel, comprising the following steps:

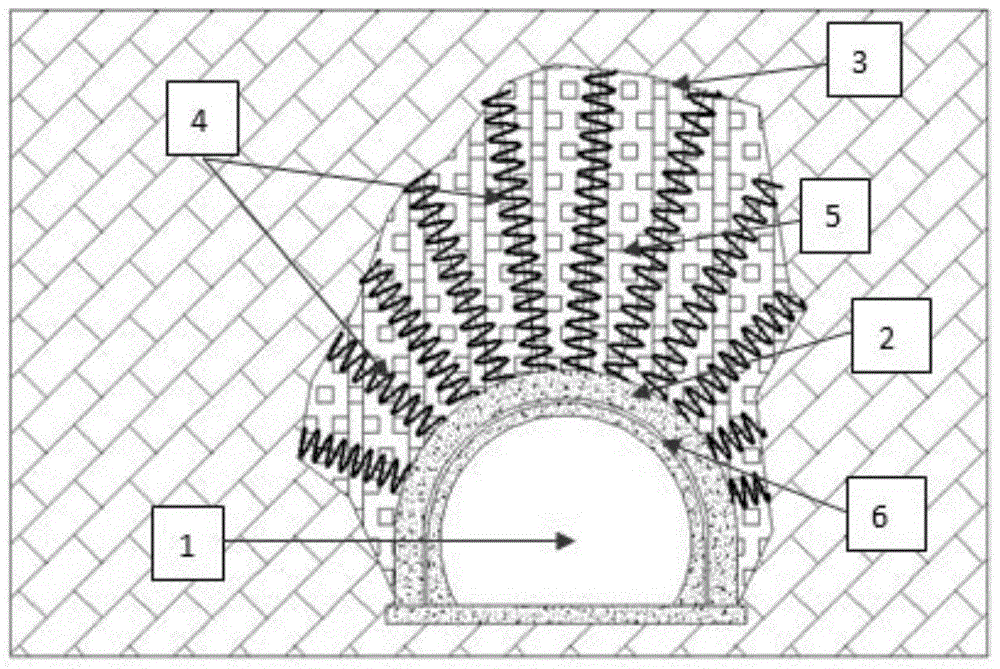

[0031] Step 1. Fill the super large spring-shaped steel frame 4 after winding with plastic foam; the details are as follows:

[0032] The steel bar is wound into a super-large spring with a designed diameter on the spring winding machine, and the plastic foam is filled into the wound super-large spring-shaped steel skeleton, and simply fixed.

[0033] The exposed rock mass at the top of the cave is effectively supported by super-large springs, and at the same time, a preload can be applied to the cave wall, which strengthens the stability of the exposed cave wall. Filling the plastic foam into the super-large steel bar effectively reduces the usage of Rockshine material, and at the same time achieves an effect similar to that of fully filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com