Control method for rotating speed of gas turbine

A speed control and gas turbine technology, applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve problems such as automatic tuning, fixed parameters, harsh working environment, etc., to achieve improved control performance, short scan cycle, and excellent overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

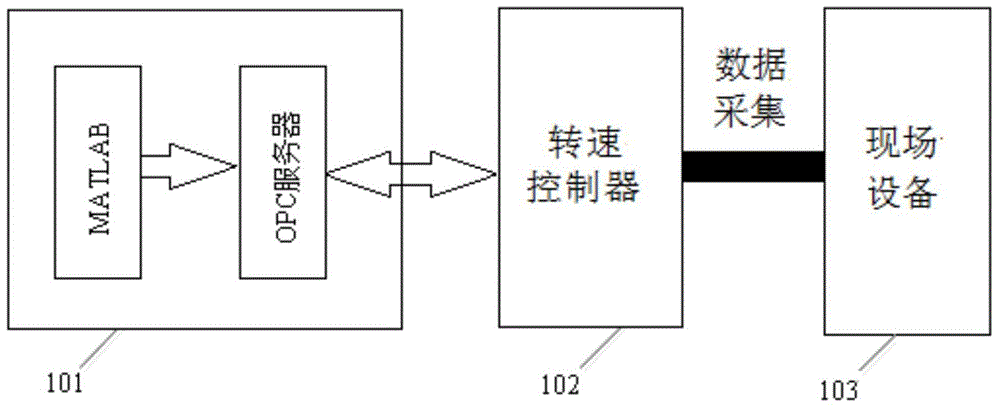

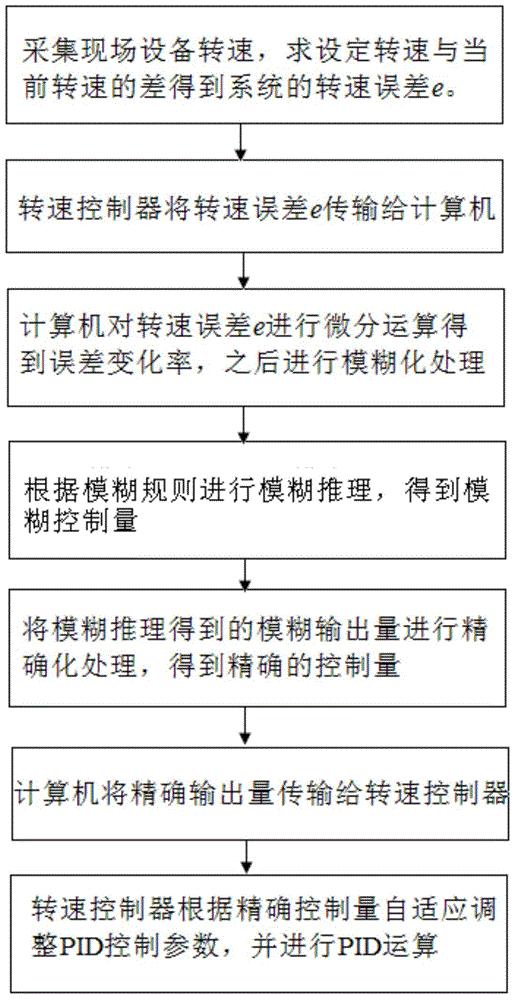

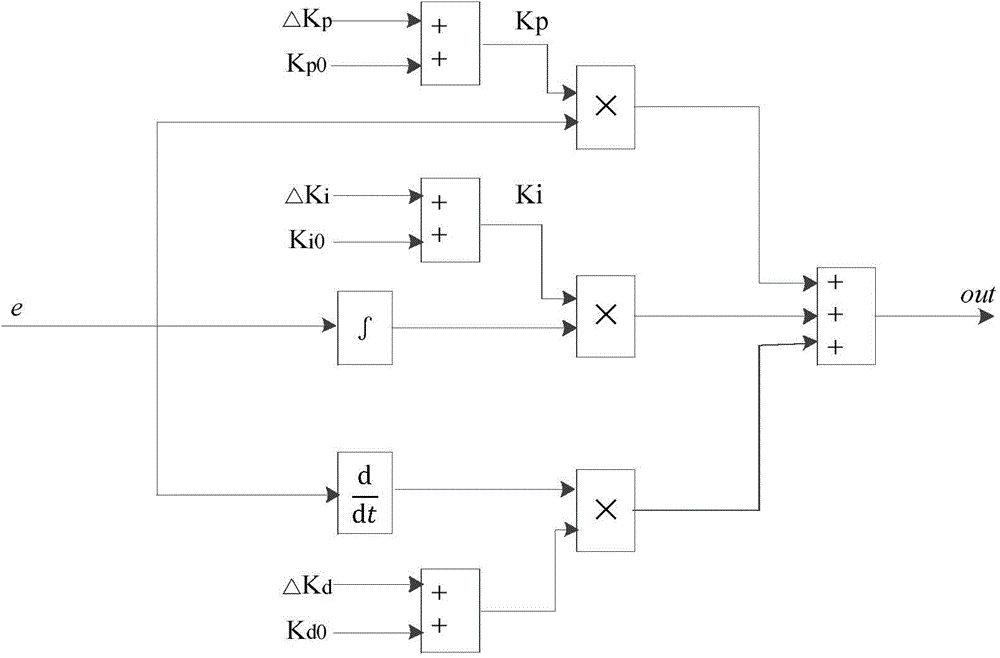

[0034] The system to realize the speed control of gas turbine is as follows: figure 1 As shown, it includes a computer 101 , a speed controller 102 and a field device 103 . The computer 101 is equipped with Matlab software to realize the fuzzy control algorithm. The computer is also used as an OPC server, and the OPC service software is installed. It provides an industrial standard interface, and its function is to communicate with the speed controller. Speed controller 102 adopts KM950 controller. The computer 101 receives the rotational speed error signal collected by the rotational speed controller 102 through the OPC server, and calculates the rate of change of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap